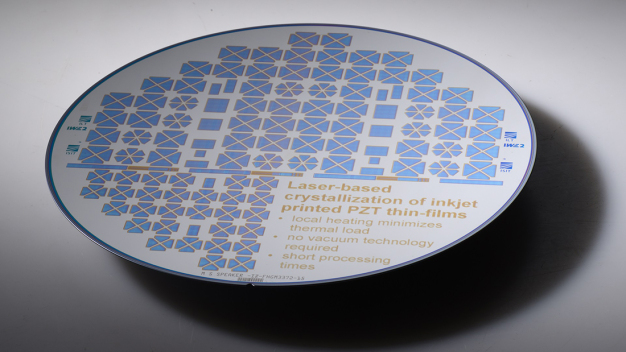

- Electronics (wafers, semiconductors, microchips,...)

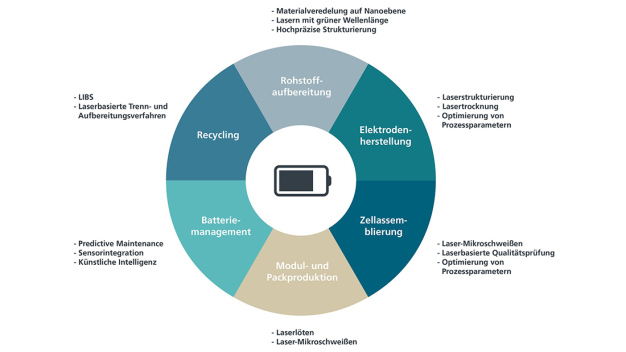

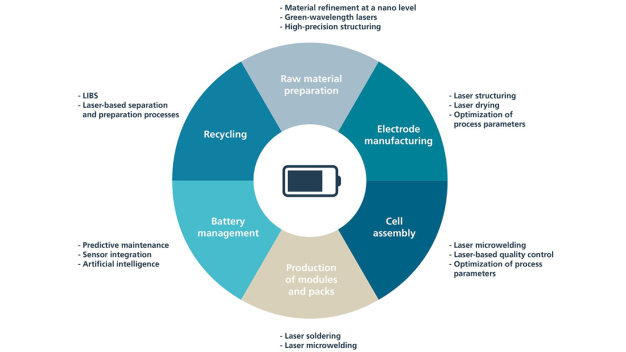

From raw material processing to recycling: new approaches in battery production

Battery production is at the heart of industrial and climate policy worldwide. Indeed, the demand for energy storage systems for electromobility and stationary applications is growing globally as is the importance of efficient, sustainable and regionally independent battery production.

In particular, the business and regulatory environment for battery production presents companies with immense challenges: For example, the dependence on raw materials such as lithium, cobalt and nickel is causing geopolitical tensions. At the same time, supply chains are becoming increasingly fragile as global crises mount and transportation costs rise. Europe is, therefore, faced with the task of building a resilient value chain that includes both raw material extraction, further processing as well as recycling – after all, used batteries are the most abundant German lithium resource. In addition, production processes must be flexibly adapted to new battery designs such as solid-state or sodium-ion batteries in order to secure investments in them.

In view of these challenges, it is clear that the future of battery production in Europe can only be secured by using state-of-the-art technologies. Laser technology in particular offers solutions to meet the key requirements – efficiency, precision and sustainability. Competitive and sustainable battery production in Europe is hardly conceivable without innovative laser processes, whether in material processing, electrode production or recycling.

Raw material processing and material refinement: the basis for sustainable battery production

Materials such as lithium and nickel are still components of current battery cells. Their chemical and physical properties make high energy densities and long lifetimes possible, but their extraction and processing pose complex issues.

However, battery technologies are developing rapidly with the industry aiming at minimizing the use of rare and expensive raw materials. The Chinese battery manufacturer CATL presented a sodium-ion battery in 2021 that completely dispenses with lithium and cobalt. In April 2024, CATL launched a cobalt-free lithium iron phosphate (LFP) battery that can power an automobile for over 1,000 kilometers on a single charge. In just ten minutes it can charge enough energy for 600 kilometers, which corresponds to a charging speed of one kilometer per second.

Toyota plans to use solid-state batteries in hybrid vehicles starting in 2025. Nissan has put a prototype production plant for laminated solid-state batteries into operation in Japan. Panasonic has presented a solid-state battery for drones. VW and Mercedes, Ford and BMW are about to introduce solid-state batteries or have entered into strategic partnerships.

A key starting point for new battery technologies is material refinement at the nano level; here, raw materials are specifically processed and functionalized to maximize their performance in batteries. This is what the Surface Technology and Ablation Department at the Fraunhofer Institute for Laser Technology is examining. With modern laser technologies it can precisely intervene in the material structure and to minimize the consumption of resources at the same time.

Another example of the successful use of laser technologies can be found in the collaboration between Fraunhofer ILT, the Chair of Laser Technology LLT at RWTH Aachen University, TRUMPF and the German Electron Synchrotron DESY. By using X-rays from a particle accelerator, the engineers have been able to gain deeper insights into laser welding processes. They showed that using lasers with a green wavelength improves material utilization and reduces waste. Their findings not only offer technological advantages, but also contribute to more sustainable production.

"These projects show that innovative laser technology can not only overcome the challenges of raw material processing, but also enable sustainable and competitive battery production in Europe," explains Dr. Alexander Olowinsky, head of Joining and Cutting at Fraunhofer ILT.

Electrode production: innovations for sustainable production

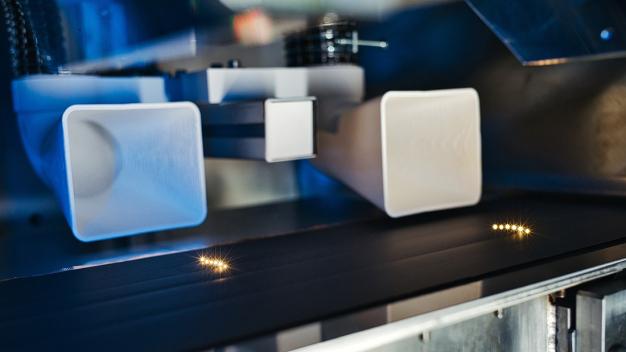

The current conductor foils (copper or aluminum) have to be coated with the electrode materials for the anode and cathode, and subsequently dried – crucial steps that influence both the energy density and the cycle life of the batteries. Conventional drying processes based on convection ovens, however, consume a considerable amount of energy and require a large amount of space, which limits the sustainability and efficiency of battery production.

The IDEEL project (Implementation of Laser Drying Processes for Economical & Ecological Lithium- Ion Battery Production), funded by the German Federal Ministry of Education and Research, shows how laser drying solves these challenges: In the project, anodes and cathodes were dried in a roll-to-roll process for the first time using a high-power diode laser. This method significantly reduces energy consumption, doubles the drying speed and halves the space required.

"Laser drying not only enables more efficient process control, but also helps to significantly improve the carbon footprint of battery production," explains Dr. Samuel Moritz Fink, group manager for the Thin-Film Processing group at Fraunhofer ILT. Together with the project partners, Fink and his team have developed a laser drying module with adapted optics and process monitoring to ensure uniform drying. This approach also offers flexibility: Existing convection ovens can be retrofitted with the laser technology, making it easier to implement the innovative process in existing production lines.

In another research project, Fraunhofer ILT is using specially developed multi-beam optics. This optical assembly splits the laser beam into several partial beams that simultaneously process a 250 millimeter wide ribbon of a lithium-ion battery anode. This high-precision structuring increases the energy density and improves fast-charging capability.

Electrode production also benefits from the integration of artificial intelligence into the manufacturing process. Researchers at Fraunhofer ILT are currently investigating how AI-supported systems can be used to optimize process parameters. Such systems may not only further increase quality and productivity, but also lay the foundation for autonomous production.

Cell assembly: precision and efficiency through innovative technologies

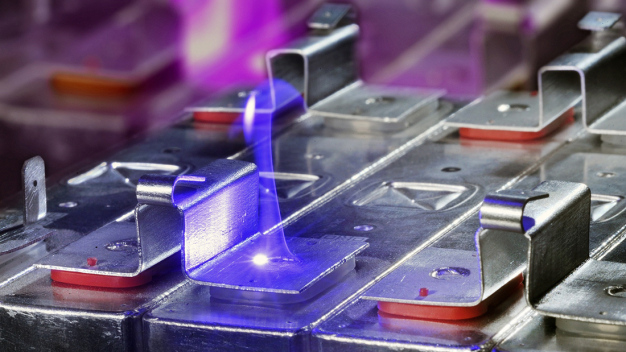

In addition to drying the electrodes, the precise joining of the electrode materials also plays a central role in the performance and reliability of batteries. Laser microwelding has established itself as a key technology here since it can join materials such as copper and aluminum, essential for battery electrodes, without contacting them and at high precision. Thanks to the low thermal load, the sensitive cell chemistry remains intact, while the electrical conductivity is optimized through reduced contact resistance. Laser microwelding provides a combination of flexibility and efficiency that traditional welding processes cannot match.

The requirements for laser microwelding vary depending on the cell format, as each cell type presents specific challenges when it comes to contacting. Cylindrical cells require a precise welding depth to ensure electrical conductivity, on the one hand, and to prevent damage due to overheating, on the other. Contacting the negative pole poses particular challenges, as excessive heat can damage the sensitive polymer seal, which could result in electrolyte leakage. In the case of pouch cells, which are characterized by their flexible design and high energy density, welding through the sensitive film coating must be avoided.

One promising development in cell assembly can be found the XProLas project, which TRUMPF is carrying out in collaboration with Fraunhofer ILT and other partners. They aim to develop compact, laser-driven X-ray sources that enable on-site quality testing directly at the manufacturer's premises, instead of using large particle accelerators as was previously the case. This new technology makes it possible to analyze battery cells in real time, allowing both the charging and discharging processes and the material quality to be monitored precisely. This method opens up new possibilities, especially when the cathode material needs to be examined; the material determines battery performance and durability. "By using brilliant X-ray sources, we can detect impurities and material defects at an early stage and, thus, significantly shorten development times," explains Dipl.-Ing. Hans-Dieter Hoffmann, head of the Lasers and Optical Systems Department at Fraunhofer ILT.

Here, too, the integration of artificial intelligence opens up additional potential: AI-supported systems can monitor and adjust process parameters in real time. With it deviations can be detected and corrected at an early stage, creating the basis for autonomous production. The vision of "first-time-right" production, in which all components are assembled without errors in the first run, is, therefore, within reach.

Module and pack production: efficiency and precision through laser technologies

The individual cells are then connected to form modules or packs. Precision plays a decisive role at the module level in particular as several weld seams need to be integrated without increasing the thermal load on the sensitive cells. Laser processes such as microwelding enable users to adapt their processes to these requirements in a tailored manner.

One of Fraunhofer ILT's key innovations is the development of processes that can be used to safely and precisely join aluminum and copper – two materials with very different physical properties. Using state-of-the-art laser beam guidance, the institute’s engineers can control welding depth so as not to damage sensitive cells.

"This technology is essential for the production of modules and packs that have to function reliably under extreme conditions, such as high currents and thermal loads," explains Olowinsky. One example of this is the laser welding of large cylindrical cells, which the Aachen-based institute has continued to develop together with partners such as EAS Batteries GmbH. Here, they are paying attention to generating a stable and durable interconnection between the cells to ensure a long service life and low failure rates.

In addition to laser welding, laser soldering has become established, particularly for joining heat-sensitive components. This process works at lower temperatures than traditional welding methods and, thus, protects sensitive electronics within the modules, making not only the battery packs more reliable, but also production more energy efficient.

Battery management and sensor integration: intelligence for future-proof battery systems

Battery management is one of the central challenges of modern energy storage systems. The safety, longevity and performance of batteries depend largely on it – and not least the acceptance of electromobility. Advances in sensor integration and the use of AI provide transformative opportunities to meet these requirements.

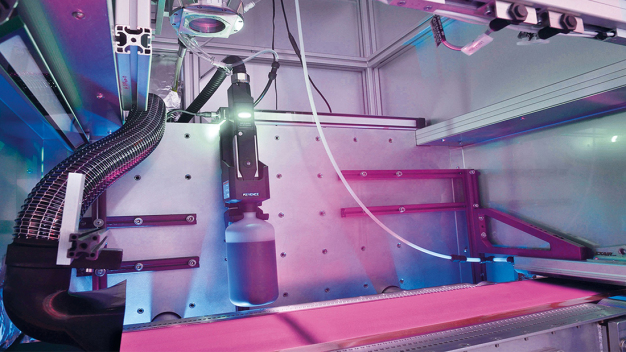

Traditionally, batteries are monitored at a macroscopic level, but this only offers limited insights into the complex processes within the cells. This is where the integration of sensor technology during production offers new possibilities. Researchers at Fraunhofer ILT print sensors directly onto components, or even integrate the smart measuring devices into them. These sensors make real-time monitoring possible, such as measuring temperatures, forces or even chemical changes within the batteries when in use.

"With additively manufactured sensors, we can continuously monitor the condition of the battery modules and react to potential defects at an early stage," explains Samuel Fink. These sensors are only a few micrometers thick, precise and resistant to mechanical and thermal stress, all of which make them ideal for use in the battery and in battery modules. Their ability to provide continuous data enables predictive maintenance, which detects potential defects before they occur.

However, the integration of sensor technology alone is not enough to implement predictive maintenance. Sensors can detect changes in cell chemistry, while AI algorithms analyze this data and make predictions about the service life of the cells. Researchers in the Data Science and Measurement Technology Department at Fraunhofer ILT are developing such AI-supported algorithms that analyze large amounts of data from sensors in real time. These systems also make it possible to dynamically adapt processes, for example by optimizing temperature profiles during cell assembly or adjusting laser welding parameters.

Recycling and reuse: the path to a circular economy in battery technology

Along with the boom in battery technology, the need for sustainable strategies to recover valuable raw materials is also growing. An effective circular economy is essential to reduce dependence on primary raw materials while minimizing the environmental impact of battery production.

In the EU project ADIR, Fraunhofer ILT is working with eight project partners from three countries to develop a sustainable recycling concept for electronic devices. The ACROBAT project aims to develop a plan for recycling lithium iron phosphate batteries before they penetrate the market on a large scale. The aim of the project is to recover more than 90 percent of the critical materials. Together with partners such as Accurec Recycling, Fraunhofer ILT is working on innovative separation and processing methods that are both ecologically and economically sustainable. The laser experts in Aachen are developing an inline characterization method to precisely evaluate the quality of the active material.

With its own laser-induced breakdown spectroscopy (LIBS) process, the institute can precisely identify and separate complex material compositions. The researchers want to adapt this technology for the recycling of used batteries to further improve the recovery of metals such as cobalt and tantalum. Here, too, AI can be integrated to analyze the large amounts of data from laser measurements and optimize the process in real time. This AI-supported monitoring enables dynamic adjustment of the recycling parameters, which reduces waste and increases the quality of the recycled raw materials.

Conclusion and outlook

Battery production is at the heart of the electromobility transition and, thus, the focus of innovations that combine efficiency, sustainability and technological excellence. The technologies and developments presented along the production chain show how state-of-the-art laser processes can pave the way for a sustainable and competitive battery industry: from raw material preparation and electrode production to cell assembly and recycling. At the same time, AI-supported analysis and control systems create a new dimension of process control that improves production quality and sustainability and further reduces production costs.

In the future, AI-supported control loops could enable autonomous production in which processes adapt to changing conditions in real time. In addition, laser-driven X-ray sources and inline characterization technologies open up new possibilities for quality assurance and material analysis.

Fraunhofer-Institut für Lasertechnik ILT

52074 Aachen

Germany