- Automation

Solutions for safe, efficient, and high-purity automation applications

At this year’s Automatica trade fair, the Fraunhofer Institute for Manufacturing Engineering and Automation IPA will be showcasing numerous solutions that – thanks in part to artificial intelligence (AI) – greatly simplify and accelerate the planning, programming, and training of robots. On display from June 24 to 27, 2025, in Hall A4, Booth 314.

Whether in the production hall, cleanroom, or laboratory, robots and other automation components are now used everywhere, primarily to assist with repetitive, physically demanding, or dangerous tasks. However, it often takes much time to install, program, and set them up. The big goal is therefore “automation of automation.” This means that setup and implementation with suitable tools is much more automated than before, saving time and money.

From June 24 to 27, 2025, Fraunhofer IPA will be presenting a whole range of solutions at Automatica in Munich that also use AI technologies to massively simplify and accelerate the planning, programming, and training of robots by (partially) automating these processes.

A software framework for all machines and systems

Scientists led by David Breunig from the research team “IT Architectures for Production” at Fraunhofer IPA have developed a software framework that enables companies to automate their entire production. This could render programmable logic controllers (PLCs) obsolete, which currently control the operation of machines and systems and are installed in large numbers in factories. “Anyone who buys a PLC from an established manufacturer today is making themselves dependent on that manufacturer’s hardware, development environment, and programming language,” says Breunig, “and that’s exactly what we want to change with our software framework.”

To demonstrate how this software-defined automation works, Breunig and his team have built a demonstrator that shows how the framework works and how it can be used. Visitors to Automatica can use it to learn about the individual modules of the software framework on screen and create or optimize their own automation projects.

Together with three colleagues, Breunig plans to start his own business with the software framework. Their start-up, retavi GmbH, will officially begin operations at the end of this year.

Flexible, intelligent mobile manipulators

Humanoid robots are currently receiving a lot of attention in the media and will also play a major role at Automatica. However, according to a study by Fraunhofer IPA as part of the AI Innovation Center “Learning Systems and Cognitive Robotics”, many companies have little interest in robots that can walk like humans. Instead, the experts surveyed see the greatest potential in humanoids being able to grasp objects with the same flexibility as humans. This is precisely where a current development from Fraunhofer IPA comes in. Due to the many degrees of freedom of a robot hand, it is not efficient to program robots extensively for these gripping tasks. To address this, Fraunhofer IPA is researching approaches for the fast and intuitive teaching of complex gripping and handling movements.

Grasping processes can be taught in simulation and with deep reinforcement learning, for example. The focus is not only on controlling robot hands, but also on intuitively instructing and teaching new applications for fully flexible robot systems – including mobile multi-purpose platforms with multiple arms and grippers. Modern methods such as imitation learning and so-called foundation models are used for this purpose. Natural language instructions, teleoperated executions, and human-demonstrated sequences are used to efficiently teach robot skills.

The demonstrator at the booth provides practical insight into selected aspects of the technology and shows examples of how central ideas from current research can be transferred into application. In addition, visitors will have the opportunity to learn more about the challenges of current imitation learning methods and foundation models, as well as how a hybrid approach can close existing gaps in a targeted manner by combining proven, parameterizable robot capabilities with learning-based methods.

Flexible laboratory robotics for handling and dispensing liquids

The prevailing shortage of skilled workers also affects laboratories and medical facilities. Existing staff spend a large part of their daily working time on monotonous routine tasks that delay higher-value, value-adding activities. Automation solutions are therefore in high demand in this environment. However, an off-the-shelf system is usually unsuitable because the tasks and objects to be handled are so diverse. Fraunhofer IPA is therefore developing a customizable software kit for autonomously operating laboratory robots that enables such routine tasks to be automated efficiently. For example, robots should be able to collect process-relevant consumables, independently dose chemicals or samples, retrieve sensitive samples from refrigerators or heating cabinets “just in time”, or, in the future, carry out experiments completely independently. To do this, the robot must be able to perform tasks such as locating and gripping a wide variety of containers, precisely weighing different liquids and solids, opening cabinets and doors, and navigating autonomously.

At Automatica, Fraunhofer IPA will showcase the current state of development with a demonstrator that can automatically dispense liquids of different viscosities to a target weight and divide them into defined target containers.

Implementing safe human-robot collaboration in a semi-automated manner

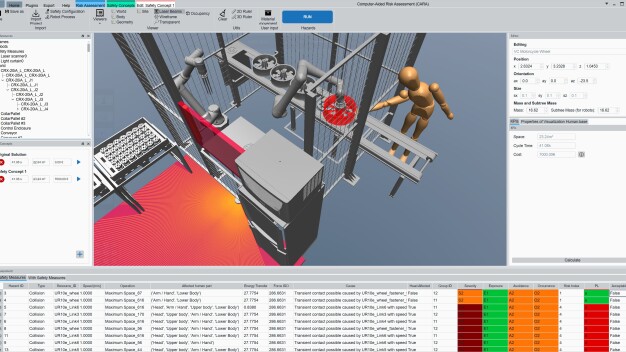

Due to small batch sizes, modern automation solutions need to be as flexible as possible. However, this also means that safety measures must be continuously adapted. This is based on risk assessment and CE marking – two processes that are currently still very time-consuming and require a great deal of expert knowledge. Fraunhofer IPA has therefore developed tools for both the planning and operation phases that simplify and accelerate safety design.

The trade fair exhibit “CARA” is a tool for the planning phase that provides comprehensive support for safety design. It uses 3D simulation to help experts plan and implement all necessary safety measures in six steps before a system is put into operation. CARA considers parameters such as potential hazards, safety distances, and possible interactions between humans and machines. Collision and entrapment hazards are automatically identified. The tool then suggests measures to reduce risk.

Collision models determined on an automated test bench developed by Fraunhofer IPA also help in the planning phase. They address the challenge that maximum permissible forces and pressures in case of collisions can limit the speeds and cycle times of the robot, thereby reducing the performance of the system. However, forces occurring during operation are difficult to calculate mathematically. Once created, the collision models enable the performance to be accurately estimated as early as the planning phase. CARA can draw on these models.

Intuitive robot programming with the help of a new user interface

Robot programming is still often a bottleneck when it comes to efficiently setting up or retrofitting an application. A new user interface on display at the trade fair booth uses a simulated disassembly application to show how the necessary expertise can be reduced and how robots can be programmed efficiently even with a high degree of variety. The user interface allows individual skills, i.e., robot capabilities, to be combined into a complete task. This is achieved using skill modules from the Fraunhofer IPA’s “pitasc” software, which can be compiled and combined for specific applications without any programming knowledge.

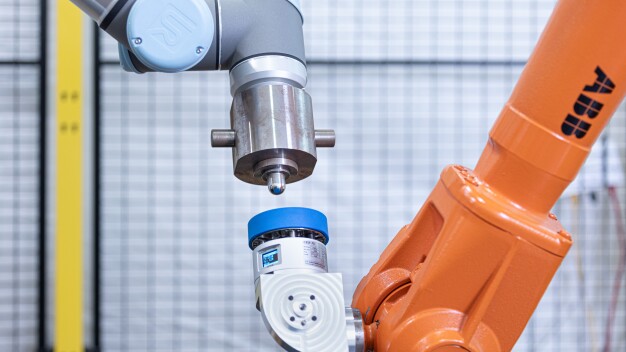

Automation in high-clean environments: 2ndSCIN® and Tested Device®

2ndSCIN® is a patented protective cover that makes robots and other moving automation components ready for use in ultra-clean production. The cover consists of a permeable, flexible, multi-layer textile that mimics the function of human skin. The textile layer is equipped with sensors that continuously measure parameters such as particle concentration, chemical contamination, pressure, and humidity. AI-based algorithms evaluate this sensor data and enable predictive maintenance, for example. Depending on the application, two or more textile layers can be superimposed and separated by spacers.

Air can be sucked in or expelled in the spaces between the layers. This allows particles from the environment or from the automation component to be removed. The introduction of special gases into the spaces between the system components enables sterilization, for example. The cover can be changed in about an hour and can be reused after decontamination. “2ndSCIN® is extremely versatile in its design, allowing us to meet individual demands. This enables us to address many requirements for cleanliness-compatible protective covers for cleanroom components that previous products have not been able to meet,” explains Udo Gommel, Head of the Clean and Dry Room Manufacturing Divison at Fraunhofer IPA. He and his team will be presenting 2ndSCIN® at Automatica.

For many years, Fraunhofer IPA has also been offering processes for particle emission, outgassing, ESD, and other requirements. The Tested Device® test mark is awarded to the products tested, and visitors to the booth can also find out more about this at the stand. The product- and customer-specific test report provides companies with confirmation of the cleanliness and cleanroom suitability of their systems, devices, or consumables. The tests include the production environments of atmospheric cleanrooms, dry cleanrooms, and vacuum conditions.

![]()

Fraunhofer-Institut für Produktionstechnik und Automatisierung IPA

Nobelstraße 12

70569 Stuttgart

Germany

Phone: +49 711 970 1667

email: joerg-dieter.walz@ipa.fraunhofer.de

Internet: http://www.ipa.fraunhofer.de