- Electronics (wafers, semiconductors, microchips,...)

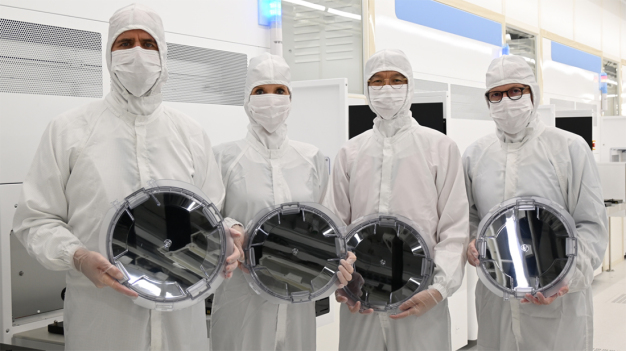

Siltronic AG produces first wafers in its new Singapore fab

On 7th November 2023 Siltronic announced the production of the first wafers in its latest state-of-the-art 300 mm fab in Singapore. The production marks an important milestone in the strategic capacity expansion of Siltronic’s global production network.

"It fills me with immense pride to see the production of the first wafers from the line. This is a decisive milestone in the history of Siltronic. I am delighted to see that the test wafer production has started slightly ahead of schedule. I would therefore like to congratulate and thank all the employees and suppliers involved for their contributions. We look forward to supplying our customers with leading-edge wafers from this new state-of-the-art fab," said Dr. Michael Heckmeier, CEO of Siltronic AG.

Despite many challenges, including the global pandemic and supply chain constraints, the construction of the new fab, which started in 2021, is on schedule and on budget. By the end of 2024, around 2 billion Euro will have been invested into this greenfield project. This will be followed by further investments on a smaller scale to further ramp the production.

The large-scale project covers an area of approximately 20 soccer fields. At peak construction times, more than 5,000 workers were on site for both construction activities and facilities installation. The fab is supported by approximately 5,500 piles which extend up to 60 meters into the ground. In total, 150,000 m³ of concrete and more than 35,000 tons of steel have been used.

In the mid-term, the new fab is expected to be highly cost efficient due to the high degree of automation and deployment of digitalization, coupled with its strategic proximity to the existing 200- and 300 mm fabs in Singapore, which will lead to economies of scale and synergies.

The new fab will serve both medium and long-term demand growth in the semiconductor market, which is driven by megatrends such as digitalization, artificial intelligence, and electromobility. As originally planned, the production ramp phase will commence from the beginning of next year.

"The trust and support of our customers has been a key factor for this investment. In the ramp phase, sales from the new fab have been secured to a high degree by long-term agreements. Customers have also contributed significantly to the initial financing of the fab through prepayments," added Claudia Schmitt, CFO of Siltronic AG.

Siltronic AG

81677 München

Germany