- R+D & Community of Interest

An impulse generator for the digital production era

Autonomous, smart, clean: from mobile and self-learning robots to state-of-the-art cleanroom technologies, methods for explaining machine learning, software tools for production, and the Stuttgart Exo-Jacket – in December 2020, Fraunhofer IPA will showcase a wide range of applications and services for automated production processes at Automatica. However, the Virtual IPA Preview will offer the first glimpses as early as June 18, 2020.

»New ideas for the automation of tomorrow« is what Automatica, the leading trade fair for smart automation and robotics, promises. Stuttgart-based Fraunhofer IPA has also taken up this concept and will demonstrate several exhibits at its trade fair stand and at further contact points on site. In an area covering 240 square meters visitors can see what is already possible today and where the journey on the shop floor of the future is heading.

Cooperative and connected navigation solutions

Compact mobile »rob@work« robots move across an elevated exhibition space. They navigate autonomously, are connected with each other and present a miniaturized logistics scenario. Thanks to a continuous SLAM algorithm, the robots reliably locate themselves even in changing environments without the need for additional infrastructure. Moreover, they exchange data with their own sensors or sensors installed in theoperational environment. This means that each robot has a permanently up-to-date map at its disposal, which it can use to adapt its route and localize itself. This avoids unnecessary paths, bottlenecks and downtimes.

»With this cooperative navigation solution, we are demonstrating how driverless transport systems could enable for example a matrix production«, explains Kai Pfeiffer, Leader of the Industrial and Commercial Service Robots group at Fraunhofer IPA. »We can also expand the exhibit to include virtual robots and use augmented reality to visualize travel paths and other information«, he adds. This simplifies and accelerates the commissioning, maintenance and expansion of the fleet. The software has already successfully demonstrated the required agility of modern logistics processes in industrial applications on several occasions.

Automated assembly and improved autonomous grasping

Many companies are focusing on the question of the extent to which they can automate their assembly tasks. For many years, Fraunhofer IPA has been offering an Automation Potential Analysis (APA) for this issue. Until now, APA has been dependent on the knowledge and input of an automation expert. A new app now makes this knowledge more easily accessible. It instructs users on how to analyze their own assembly processes, evaluates their answers and provides information on automation potential. »With our app, anyone can become an expert in the evaluation of assembly processes«, says Alexander Neb, a research scientist at Fraunhofer IPA who co-developed the app. It can be obtained via a simple license agreement for test use.

NeuroCAD is another software tool for assembly automation. It uses machine learning methods to analyze component properties and uses this information to determine the extent to which a work piece is suitable for assembly automation. Users can upload their STEP files free of charge to www.neurocad.de and receive feedback within seconds how easy or difficult it is to singularize a work piece with a robot, e.g. bin picking. The tool also evaluates the gripping surfaces and alignment potential of the component. In addition, the neural network ensures a high probability that the results are correct.

Finally, the pitasc modular system for programming force-controlled assembly processes shows how manually executed processes can be automated in an economically viable way. »Until now, it has largely been necessary to re-program a robot system for each application. With our software, tasks that have been modeled once, can be quickly transferred to new product variants, products and even to robots from other manufacturers«, says Frank Nägele, Head of the Robot Programming and Control group at Fraunhofer IPA. The software is structured as a modular system: it contains many ready-to-use and reusable program modules that can be individually configured when setting up a robot process. The pitasc system is ready for use in pilot applications that the scientists would like to implement working together with companies.

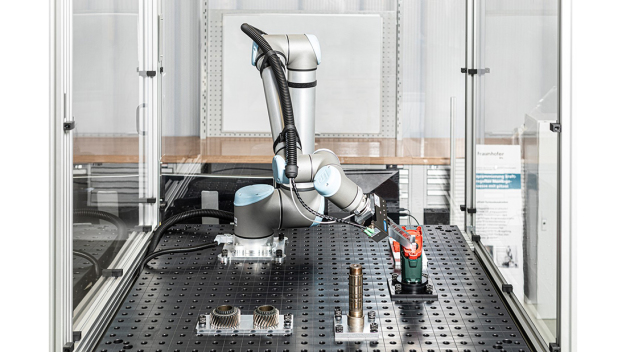

Not only assembly, but also »bin picking« applications can present automation with a challenge. Fraunhofer IPA’s »AI Picking« exhibit shows how machine learning methods and simulations significantly improve the autonomy and performance of the application.

The scientists demonstrate this using the example of a robot that separates objects from an undefined position out of a bin. An object localization based on artificial intelligence (AI) provides sound and accurate object positions within a few milliseconds. »New objects can be teached in quickly and easily on the basis of a CAD model«, explains project manager Felix Spenrath. »The software can also avoid any obstacles and detect and release entanglements as well as handle packaging material in a robust manner«. The robot has already been extensively trained in simulation and this knowledge subsequently been transferred to the real application. Grasping points are automatically generated and evaluated based on this knowledge.

Contamination-free production with protective cover and cleanroom tent

The demand for more autonomous as well as ultraclean production is increasing. »Clean production environments are facilitating a high-tech future«, explains Udo Gommel, Head of the Ultraclean Technology and Micromanufacturing department at Fraunhofer IPA. »Tomorrow’s key technologies will only be advanced using ultraclean technology. It is crucial: from battery production right through to biotechnology.«

2ndSCIN® protective technical skin: Recently patented, 2ndSCIN® makes dynamic automation components such as robots ready for use within ultraclean environments. The cover consists of a permeable, flexible and multi-layered textile, which is similar in its functionality to human skin. Depending on the application area, two or more layers can be superposed. The layers are each separated with spacers. Air, for example, can be absorbed or discharged in each interspace. In this way, particles from the environment or automation components are removed. A gas feed into the system’s interstices enables it to be sterilized. In addition, the protective technical skin can be changed in about one hour and be reused after decontamination. The textile layers are also equipped with sensors that continuously measure parameters such as particle quantities, pressure and humidity. In the future, this sensor data will be evaluated using AI algorithms and will, for example, enable predictive maintenance. »2ndSCIN® is extremely variable in design, so we can implement individual requirements. In this way, we address many of the requirements for protective technical skins for cleanroom components that products seen up until now have been unable to meet«, explains Gommel.

CAPE® mobile cleanroom: Scientists from Fraunhofer IPA have also developed a mobile, tent-like cleanroom system that can be set up in less than an hour both indoors and in weather-protected outdoor areas. This »Cleanroom on Demand« provides manufacturers with a mobile, contamination-free production environment that enables air purity of ISO classes 1 to 9. This is particularly attractive for manufacturers who need contamination-free manufacturing surroundings but do not require a permanently available sterile and clean environment. CAPE® is suitable for use in chip production, medical technology, the food industry and satellite assembly, for example. The automotive industry also benefits from the cleanroom tent, for example in battery cell or fuel cell production. »CAPE® can even be used in crisis areas to provide a clean and sterile environment, for instance if there is no operating theatre on site«, says Gommel.

Fraunhofer Tested Device®: For many years now, Fraunhofer IPA has also been offering methods for particle emission measurement and awards audited objects the »Tested Device®« certification. During Automatica, this method is demonstrated by means of an optical particle counter and a test object within the CAPE® mentioned above. Product and customer-specific test reports provide companies with confirmation as to the cleanliness and cleanroom suitability of their systems, devices and consumables.

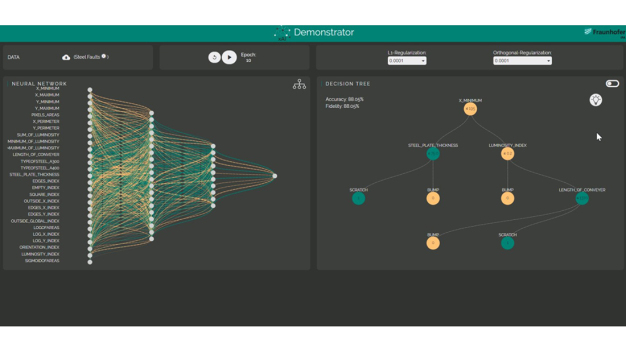

Explaining machine learning and communicating data

In robotics as well as in numerous other application areas related to production and services, the use of machine learning methods and artificial neural networks is on the increase. Depending on the application, it becomes more and more important to know exactly how these work and why they achieve a certain result: In essence, they have to be explainable. Due to their complexity, in many cases, this is not yet possible. »The more powerful a neural network is, the more difficult it is to understand«, explains Prof. Marco Huber, who heads the Center for Cyber Cognitive Intelligence (CCI) and the Image and Signal Processing department at Fraunhofer IPA.

For this reason, at Automatica, Fraunhofer IPA will be presenting processes under the slogan »Explainable AI« (xAI) that visualize decisions made by neural networks and make them transparent and comprehensible to the user. »This traceability strengthens acceptance of AI, creates trust, improves the correct functioning and provides legal certainty«, explains Huber.

Data accumulates in every production process, but due to different formats and interfaces, it is often not possible to use and evaluate it. This is exactly where the »Station- Connector« software comes in to play, offering a uniform interface across every facility. It allows data to be transferred easily and in an application-specific manner between industrial protocols, control systems and any IT systems. »With our software, users can quickly generate and implement data-based business models«, says Marcus Defranceski, who leads the group Clean Automation Technology within the department Ultraclean Technologies and Micromanufacturing at Fraunhofer IPA. The exhibit on display at the stand shows how easy and flexible the software is to use and how it can be implemented for a wide range of applications, such as AI processes or monitoring.

Increasing the efficiency of production processes and easing employee workloads

A demonstrator for autonomous production optimization shows how losses in production can be detected automatically and their causes determined. It depicts an automated model of a production line. This is monitored both by the control system and external sensors, such as light barriers and cameras. All observation sources are used to create a behavioral model of the line. This allows the line to be continuously analyzed online and, in this way, its normal behavior can be recorded and production losses identified. »In this way, we are aiming to increase the efficiency of the entire production line and make central process parameters transparent«, explains Julian Maier, scientist at Fraunhofer IPA and co-developer of the demonstrator.

The flexible manpower engaged in production is still irreplaceable in many places, despite numerous automation possibilities, and it is important to retain this as far as possible. Exoskeletons, i.e. robot systems that are worn directly on the body, provide strength and support for demanding physical activities and relieve the strain on humans. Fraunhofer IPA has developed the Stuttgart Exo-Jacket (SEJ), an exoskeleton for research and development purposes. The SEJ actively supports the upper extremities during lifting and overhead activities. The current system on show at the IPA stand, the Stuttgart Exo-Jacket 2, is mainly aimed at applications in logistics, where workers use both hands to manually handle objects such as tires, crates and suitcases between knee and shoulder height in front of the body.

»The core idea behind the system is that users can continue to move their hands to the best of their ability and in this way make optimum use of their handling skills«, comments Christophe Maufroy, Group Leader for Physical Assistance Systems and Smart Sensors at Fraunhofer IPA, describing the particular features of the SEJ. The exhibit also focuses on measurable ergonomic workplace analyses and optimization.

Discover and make use of AI initiative

Last but not least, the Fraunhofer IPA trade fair stand will also provide information on an initiative in the context of artificial intelligence. The »pitasc« and »AI Picking« exhibits are part of the »Cognitive Robotics« initiative sponsored by the state of Baden-Württemberg. It aims to further advance innovative robotic technologies and to translate skills such as perception, learning, anticipation and adaptation into applications. In this way, the cognitive robot offers solutions to confront the challenges associated with production and other processes of the future, which have been triggered by social megatrends. The involvement of industrial partners creates a network which ensures technology transfer.

![]()

Fraunhofer-Institut für Produktionstechnik und Automatisierung IPA

Nobelstraße 12

70569 Stuttgart

Germany

Phone: +49 711 970 1667

email: joerg-dieter.walz@ipa.fraunhofer.de

Internet: http://www.ipa.fraunhofer.de