- R+D & Community of Interest

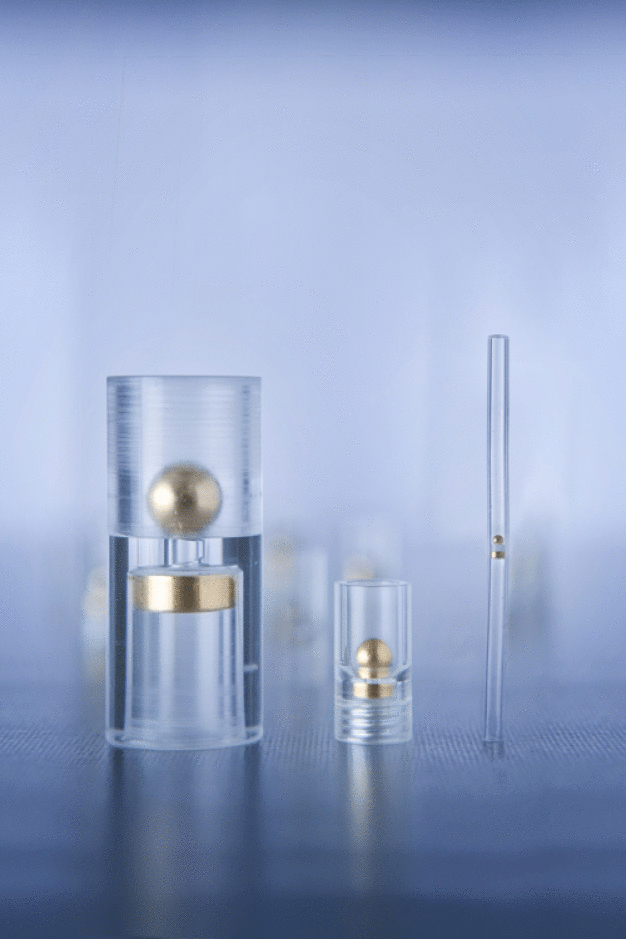

Klaus Jacob

A clean take off into space

Components used in space missions have to be extremely clean. Over the last few years, Fraunhofer IPA has made a name for itself, especially concerning systems that not only clean things but are also capable of supplying exact information about the quality of their work. To achieve this, the Stuttgart-based institute has a range of highly-precise analysis devices at its disposal. It also has the world’s most sophisticated cleanrooms.

It all started with a surprising request. The European Space Agency ESA wanted to know if Fraunhofer IPA was capable of sterilizing diverse components for a mission to Mars. Udo Gommel, head of the business unit »Electronics and Microsystem Technology«, didn’t see much of a chance of being given the opportunity to tackle this challenging task. That’s because he wasn’t the only person who had been asked. Neither did he have any experience in the aerospace business. »Being a manufacturing specialist, I really didn’t think they’d be interested in me«, he recalled. However, he did know a lot about cleaning delicate electronic components that are used in the semiconductor industry and in medical engineering, for example. He also had the advantage of working at a place where one of the world’s best cleanroom laboratories is located. And that’s what finally tipped the balance: he got the job. That was seven years ago. Meanwhile, space travel has become a focal point of his business unit. At the moment, over 20 projects are running on a range of topics. »Once you’ve gained a foothold in the industry, more and more people take an interest in you«, said Dr. Gommel. Whenever there’s a particularly difficult challenge to be tackled, when commercial solutions don’t work and research is called for, that’s when the team from Stuttgart comes into play.

Safety first

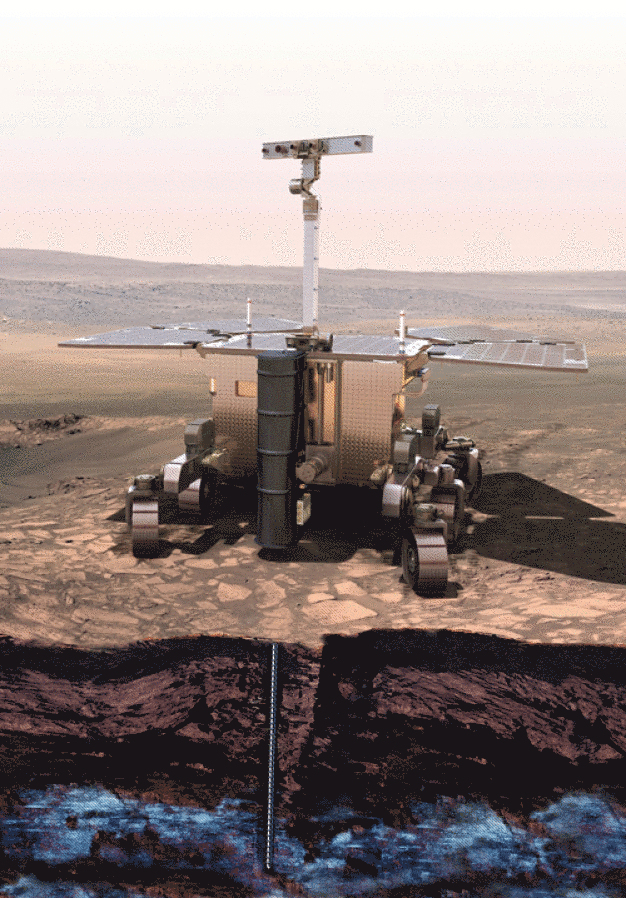

In space travel, safety is the top priority because peoples’ lives are at stake – and a lot of money, too. If a plane crashes, hundreds of passengers die. And a space mission often costs as much as a whole skyscraper. Because an unmanned space probe can’t be repaired once it‘s been launched, a fault in a component costing just a few cents could lead to a total disaster. Then all the hard work would have been for nothing and the scientists would have to wait for years before they got the chance to try again. »Failure is not an option«, is what they say in the space industry. Not a single component or aggregate may fail. Contamination is one of the main causes of failure because dirt is regarded as poison for all materials: it can jam the mechanics, cause a short or damage electronics. Things get tricky if this concerns a probe that should search for signs of life on a distant planet. And that’s what the European Mars mission »ExoMars« is all about, which is still keeping the experts in Stuttgart busy today. »ExoMars« is due to take off in 2018: a landing module will land on a neighboring planet from where it will launch a vehicle about the size of a Smart. In order for its sensors to function reliably while searching for traces of life, it may not be contaminated with any organic material from Earth. Otherwise, it will suffer the same fate as its American predecessor »Curiosity«, which announced success back in 2012. For months, experts used their on-board equipment to analyze the substances they had found, until they came to the conclusion that it was a false alarm: the devices had detected contamination from Earth. Consequently, to avoid such a mishap from happening again, each component has to be absolutely free of microorganisms. Not even residues of dead microbes may be stuck in crevices. Such pedantry has since become an integral part of space travel for economic reasons, too. In the »Planetary Protection Program«, institutions such as ESA and NASA have pledged not to introduce any germs from Earth to other planets. Additionally, they have to make sure that no hazardous substances of extraterrestrial origin are brought back to Earth – if a return flight is planned, of course. The euphoric scenes, such as those seen in 1969, would never take place today. Back then, the first astronauts who traveled to the moon were embraced by elated people just after their return. And the space travelers also presented a box containing lunar rocks to Richard Nixon, who was President at the time. Now there is a specially-trained »planetary security officer« to make sure that such scenes aren’t repeated and that all rules and regulations are strictly upheld. He’s a regular visitor to Stuttgart these days.

The cleanest cleanroom in the world

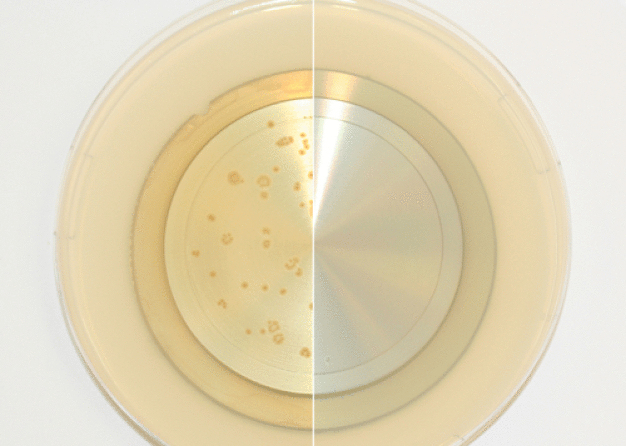

In order to fully sterilize the Mars rover, the experts in Stuttgart designed a cleanroom for ESA which has since been erected in Noordwijk in the Netherlands, where the headquarters of the European Space Research and Technology Centre (ESTEC) is located. Such thorough cleaning procedures can only be carried out in a cleanroom because huge numbers of dust particles present in the air would otherwise recontaminate the components immediately. The world’s most sophisticated cleanroom is located at Fraunhofer IPA. It fulfills the highest cleanliness standards - ISO Class 1, meaning that a maximum of 10 particles just 0.1 micrometers in size may be contained in one cubic meter of air. An ISO Class 9 cleanroom, one of a comparatively much lower level of cleanliness, would contain 109 particles, i.e. one billion times more. In the air normally found in a town, around 1013 particles are suspended in each cubic meter of air; when there’s smog, there are even more. To maintain this highest cleanliness class, a huge effort is required. Visitors notice this as soon as they walk into the IPA building: immediately behind the door, a knee-high bench stops them from walking any further. Before they are allowed to step over it, they have to put on plastic overshoes. Smoking is prohibited throughout the building. Despite these precautions, the particle count is only reduced by the factor of 10.

The actual cleanrooms, which can only be entered via locks, are hermetically sealed like a house within a house. You can watch the scientists in their sterile suits as they work behind high walls made of glass. Inside, the air pressure is slightly higher, which stops any unfiltered air from getting in. A laminar airflow, which is introduced via the ceiling and extracted via the floor, prevents any dust particles from remaining in the room. With an airflow of 50 centimeters per second, the complete volume of air contained in the room is exchanged within seconds. Any particles that might be generated when a scientist rubs his gloves against one another, for example, disappear straightaway through the perforated floor. To prevent turbulences, which would impair the air exchange, the engineers work without the aid of an overhead crane. The entire ceiling is made up of filter elements. And the floor is raised to enable the air to be extracted effectively. In this ultra-clean environment, you can even measure how much abrasion is generated when a robot arm or a cable is moved. The only other ISO Class 1 systems in the world of this kind are located in Holland and Romania. Both were designed by experts from Fraunhofer IPA but the cleanrooms in Stuttgart are the largest. The most imposing one is 6.50 meters high. Its raised floor can bear loads of up to 6 tons per square meter, making it unique throughout the whole world.

Carbon dioxide snow and ultrasound processes

To sterilize the Mars rover, a technique developed at Fraunhofer IPA and for which a patent is pending, proved to be the most effective option. It’s actually the further development of an existing process. The technique was originally implemented in the USA to remove paint from the bodies of aircraft. A hard jet of frozen carbon dioxide crystals the size of rice grains is used to practically blast off layers of paint from the metal surface. The team of experts in Stuttgart have since comprehensively refined this rough tool. Instead of ice crystals, they use carbon dioxide snow. The trick: the jet emitted from the nozzle is additionally accelerated by a jacketed jet of nitrogen, thus allowing it to penetrate into crevices and remove the smallest traces of contamination. As soon as the tiny snowflakes impact on the relatively warm surface, they are converted to gas at an explosive rate, which increases their volume by around 800 times. The detonation pressure blasts any traces of contamination away immediately, even fingerprints, which are made brittle beforehand by the cold gas. The only disadvantage is that carbon dioxide is expensive. It costs 1000 Euros to produce just 30 kilos – and they’re used up after just ten minutes. To make life easier, Fraunhofer IPA has installed a supply system, which alone cost 800,000 Euros to build.

Blasting with carbon dioxide is just one way of cleaning industrial components. There are about three dozen other methods, which Fraunhofer IPA is currently spending a lot of money on to improve. These range from wiping and rinsing steps to plasma-based cleaning processes. Some techniques, such as ultrasound, only work in combination with moisture or a liquid, making them unsuitable for cleaning electrical or electronic components. Others, such as the carbon dioxide technique, are dry-cleaning processes, which makes them especially gentle. There are rough and fine cleaning steps, pre-cleaning and final cleaning processes. The method that is finally chosen depends on the level of cleanliness required and the type of component involved. The semiconductor industry has the highest requirements, thus making it the pacemaker for cleaning technologies. The reason for this is because structures on chips are so small nowadays that a particle just a few nanometers in size is enough to cause a short. In the automotive industry, requirements aren’t quite so high. Here, only particles upwards of 200 micrometers are considered to be critical, with metallic contamination causing the most problems. Space travel requirements lie somewhere between these two, with particles upwards of one micrometer usually being the most problematic.

Million-Euro component: cleaning in record time

However, the aerospace industry is fussy about other things. Each component is produced singly, from aluminium frames to tiny washers. There’s no assembly line in this profession. Furthermore, every processing step has to be carefully documented. Here, NFC tags should make life easier in the future. They record information about the processing state of each individual component. This enables every step in the history of even the tiniest screw to be reconstructed, from its fabrication right till its final assembly. It’s the only way to find out the exact cause of a failure. Of course, just cleaning components isn’t enough. After that, they have to be packaged to prevent them from getting dirty again. That might sound trivial but this is also a very demanding task because particles could become detached from packaging materials and cause re-contamination. Special containers made from high-grade steel have proven to be the best answer. Sometimes components lie dormant inside them for years before a satellite is finally launched.

The amount of work carried out by the experts to clean components could be seen last November. Fraunhofer IPA had to clean 13,000 parts of an Earth observation satellite. The largest component was an aluminium segment that had been cut from a block weighing 200 kilos. The delicate structure had to be cleaned very carefully to prevent even the smallest amount of damage from occurring. This aluminium structure alone involved a huge effort on the part of the institute’s employees. To pre-clean the heavy component, the filter ceiling of the cleanroom would have had to have been removed to install an overhead crane. But this would have impaired the optimum airflow required. The answer was to construct a temporary decontamination cell, which not only met stringent cleanliness demands but also solved the load problem. Things had to be done fast to prevent the tight time schedule of the project from being endangered; the temporary cleanroom the size of a small house was erected within the space of a week.

The broad spectrum of services offered by Fraunhofer IPA also enables additional processing steps to be carried out on site if necessary, such as painting. This does away with having to transport components from one place to another and excludes the risk of them becoming re-contaminated in the process. A lot of work is also needed to assess the quality of cleaning processes. If particles in the micro- or nanometer range are involved and information about their exact number is required, highly-precise equipment is called for. In this regard, Fraunhofer IPA spares no expense. A fully-automated field emission scanning electron microscope is capable of detecting even nanometer-sized particles. It can scan a component the size of a mobile phone and count the number of particles adhering to its surface. Stuttgart has a scanning electron microscope in Stuttgart, which scans surfaces with a tiny needle. It also has a thermodesorption gas chromatograph coupled with a mass spectrometer for finding the tiniest traces of organic contamination.

Establishing practicable standards

Only with such enormous efforts can optimum cleaning methods be developed for special applications and different cleaning processes be compared with one another. That’s why the scientists from Stuttgart are on the relevant committees in charge of standardizing cleaning methods. Dr. Gommel works for ISO, the International Organization for Standardization, as well as for ECSS, the European Cooperation on Space Standardization. In addition to these, he’s a member of the work group »Cleaning«, where he is responsible for the guideline sheet »Ultra-precision cleaning for flight hardware«.

Fraunhofer IPA also supports many other major branches of industry in different areas, such as the power industry. A reliable energy supply is essential to a mission’s success. The most recent example of this is when the signal to the mini-lab »Philae« was lost due to a lack of power shortly after it landed on the comet »Chury«.

If you talk to Dr. Gommel about the role of Fraunhofer IPA in space travel, he sees it as being a »hidden champion«. That’s how he felt seven years ago when ESA chose him instead of any of the other competitors on the scene. And that’s still the case today. Because a hidden champion isn’t just a secret winner but also an unknown world market leader.

![]()

Fraunhofer-Institut für Produktionstechnik und Automatisierung IPA

Nobelstraße 12

70569 Stuttgart

Germany

Phone: +49 711 970 1667

email: joerg-dieter.walz@ipa.fraunhofer.de

Internet: http://www.ipa.fraunhofer.de