- Ultrapure media (water, ...)

Elke Droste, Area Sales Manager, Pharmatec GmbH, a Syntegon Company

When the chemistry is right

Vetter expands capacities with PW generator from Pharmatec

The production of injectable APIs is a highly complex process that leaves no room for error. But everything is easier when the chemistry is right, in both the literal and the figurative sense – as the Syntegon subsidiary Pharmatec and Vetter proved during the installation of a new purified water (PW) generator as part of the site expansion in Langenargen, Germany. The successful collaboration also laid the foundation for an extended partnership between the two companies.

With over 75 years of experience, more than 7,000 employees worldwide, and sites in Europe, Asia, and the US, Vetter Pharma-Fertigung GmbH & Co KG is a leading global Contract Development and Manufacturing Organization (CDMO) for injectable APIs. Vetter supports pharmaceutical companies with comprehensive fill-finish services along the entire value chain. Its range of services extends from clinical development, aseptic filling, and visual inspection to the assembly of complex injection systems. Secondary packaging, analytical quality control, and support with regulatory issues are also part of Vetter’s portfolio.

Laying the foundation for growth

The company's services are popular: Vetter is experiencing long-term growth and a steady increase in demand. To meet this demand, the company has been investing in the expansion of its portfolio and sites for years. One of these is Langenargen in Germany, where Vetter has been filling liquid and lyophilized products into vials and syringes since 1998. The facility currently has four filling lines, two more will be added in the future. This requires meeting certain conditions. For example, a sufficient supply of pure media such as water or steam for feeding and cleaning the lines is essential.

Until recently, two generators with a total volume of 15,000 liters per hour produced purified water (PW) by reverse osmosis in Langenargen. Whenever the larger of the two units was out of operation for sanitization purposes, the smaller one was no longer able to meet the demand for PW. To secure production capacity and prepare for an increase in the future, Vetter needed another PW generator.

Pure media in pharmaceutical production

Purified water plays a central role in the pharmaceutical industry – both for cleaning production systems, format parts, or containers and as a basis to produce other water quality levels such as highly purified water (HPW) and water for injection (WFI). The purified steam (PS) required for sterilization is also produced from PW.

Quality requirements for these pure media are strictly regulated, for example by the European Pharmacopoeia (Ph. Eur.) or the US Pharmacopoeia (USP). Vetter even goes one step further and sets its own, significantly stricter limits regarding the microbial count in PW to ensure maximum patient and product protection. This was also one of the specifications for the project in Langenargen: Vetter was looking for a solution that could produce PW in WFI quality.

A rigorous selection process

Dietmar Waizmann, Head of System & Service Media in Langenargen, has been with Vetter for over 30 years. He was well aware of the requirements for PW production at the site – and began a careful selection process: “We drew up a very comprehensive specification sheet,” Waizmann explains. “This served as the basis for us to take a close look at the offers from various manufacturers and compare them with our needs.” The PW generator from Pharmatec impressed from a technical standpoint, amongst others with its capacity control, which automatically adapts to the requirements of the storage tanks and ensures rapid availability even if the containers are temporarily emptied.

Despite its price advantage, the unit has a longer amortization period compared to competing ones, mainly due to its lower yield. Moreover, Dietmar Waizmann's team had not yet worked with Pharmatec as a project partner before. However, the team was able to convince Vetter that the system is more stable and reliable than others in the long term, if it is not pushed to its limits. After the first meeting, Waizmann was already convinced that he had found the right partner in Pharmatec. The decisive factors were not only the likeable manner and technical proficiency of the experts, but also their flexibility and willingness to respond individually to the special conditions on site – particularly regarding space constraints.

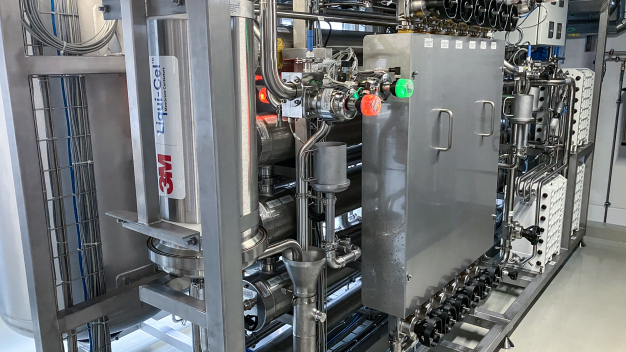

Made to measure

Nick Eilenberger, Engineer Process Design and Project Manager at Pharmatec, recalls: “The available floor space was actually too small. But if it’s necessary, we are happy to deviate from the standard.” During an on-site visit, the available space and the existing connection options were measured precisely, and a custom-made unit was designed. The project team faced yet another space problem during installation: Due to the construction of a new production facility opposite, space for delivery and installation of the new unit was limited. “We simply planned the frame in two parts, delivered it like this, and assembled it on site during installation,” Eilenberger explains.

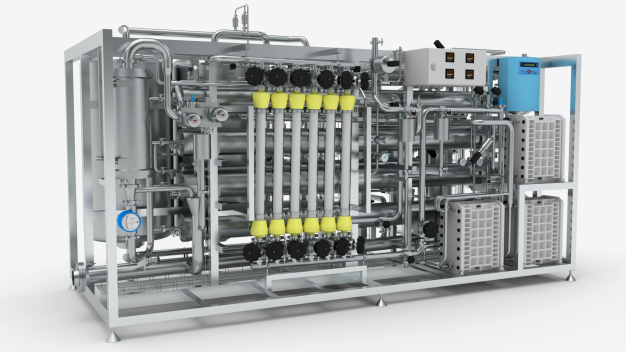

The PW generator, which Vetter uses to feed the distillation systems for WFI processing and to clean, for example, format parts and syringe bodies before autoclaving, has a capacity of 10,000 liters per hour and includes several process stages. First, the potable water is softened in an ion exchanger. Reverse osmosis is used to reduce the ion content of the softened water and retain the majority of germs and endotoxins. The CO2 content is then reduced by membrane degassing, followed by electrodeionization and ultrafiltration to remove residual ions, germs, and endotoxins. The entire system can be sanitized with hot water.

A partnership built to last

Once installed, commissioning and qualification of the new system went smoothly. “This was not the only time we received excellent support from Pharmatec,” reports Dietmar Waizmann. “I was really impressed by their good availability, flexibility, and productive and friendly cooperation. The chemistry was just right.” In fact, the successful project in Langenargen laid the foundation for further cooperation between Vetter and Pharmatec. Two more PW generators and softeners have already been installed at the Vetter site in Ravensburg, and two further PW generators with integrated softening in Rankweil, Austria. Dietmar Waizmann is convinced: “Pharmatec is the right partner for us to continue on our growth journey and shape the pharmaceutical industry of the future together.”

![]()

Syntegon Technology GmbH

Blaufelder Straße 45

74654 Crailsheim

Germany

Phone: +49 7951 4020

email: packaging-ph@syntegon.com

Internet: http://www.syntegon.com