- Conversion

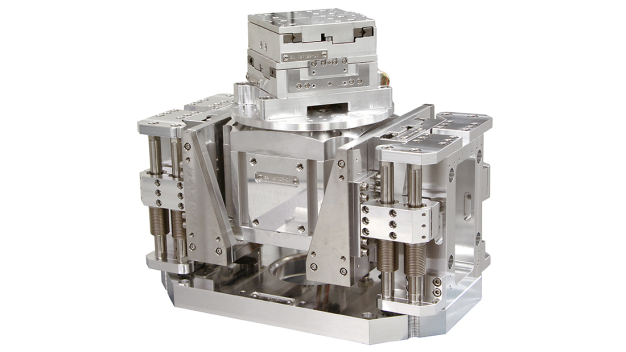

Magnifying glass clean and highly precise

Aerotech continues its expansion and doubles its cleanroom capacities, among other things

Aerotech, manufacturer of high-performance motion control and positioning systems as well as automation solutions, is responding to increasing global demand by further expanding its headquarters in Pittsburgh. Following the recent expansion of the production area and the purchase of additional systems and machines, the clean room area is now also being doubled. The branches in Germany and Great Britain are also to benefit from this. The subsidiary Kiski Precision Industries (KPI), a supplier of mechanical components, just announced the acquisition of the neighbouring company Alpha Carb Enterprises (ACE), which more than doubles the operating space to 79,500 sqm.

With a broad product range specialising in nanometre positioning, Aerotech has carved out a solid niche in the field of high-precision motion control over the past 50 years. Aerotech Ltd, UK, and Aerotech GmbH in Fürth, Franconia, were the first European subsidiaries to drive the international expansion of the medium-sized US company. In the meantime, the company has grown to approx. 500 employees worldwide. The spectrum of industries ranges from medical technology and life science applications, to photonics, semiconductor manufacturing, automotive and data storage, to laser processing, aerospace and measurement and testing technology.

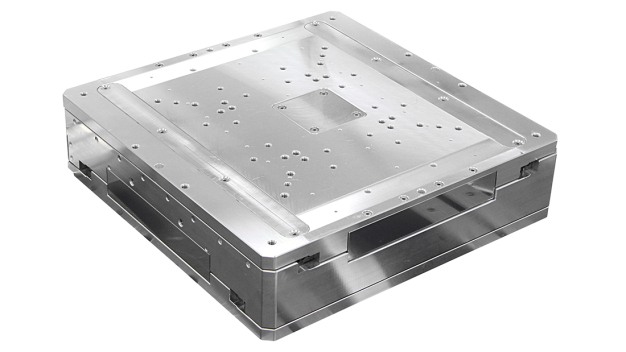

"Many of our customers come from highly regulated industries with high process requirements. To keep the amount of airborne particles, particulates or germs as low as possible, sensitive products such as catheters or lenses are manufactured exclusively in clean rooms," explains Simon Smith, European Director Aerotech. "In the interest of our customers, we also ensure constant conditions and avoid any contamination during the production of our positioning systems." He adds that it is imperative to live up to this promise of quality, even as demand increases. "We take our manufacturer obligations very seriously - in order to be able to produce larger quantities under the best conditions, we are currently expanding our clean room capacities at our headquarters in Pittsburgh."

Significant investment in new space and equipment

At the end of the construction work, the cleanroom will have an area of 600 m², which is about twice the original size. It will be expanded to ISO class 6 with cell-specific areas of ISO class 5. Additional investments will be made in cleanroom clothing, work equipment, tools and complete product ranges.

The cleanroom expansion is considered a continuation of a multi-year investment in facilities and operational capacity that began back in 2018. Aerotech added an additional 134,500 square feet of manufacturing, office, engineering and laboratory space to its Pittsburgh facility.

The new cleanroom capacities will then also benefit Peak Metrology. The youngest Aerotech subsidiary, also located in Pittsburgh, is currently on a rapid growth course. The experts there, led by RJ Hardt, concentrate exclusively on industrial customers in the field of surface metrology. Peak Metrology offers a wide range of products for this purpose - right up to turnkey machines. Already as a business unit of Aerotech, a broad customer base could be built up around standard and customised precision solutions for surface metrology.

Kiski Precision Industries acquires Alpha Carb Enterprises

Kiski is also pleased to see the rapid growth of Aerotech's subsidiary Kiski Precision Industries (KPI), which provides metalworking services such as CNC machining, precision grinding and wire EDM, as well as assembly services for Aerotech. Kiski announced in early December 2022 the acquisition of Alpha Carb Enterprises (ACE), a neighbouring manufacturing company focused on wire EDM in the tool and die industry, among others. According to KPI, the addition of 7,390 sqm doubles the available operating space - a critical factor as current production facilities are at capacity. ACE also offers complementary business lines and a broad range of expertise and experience that makes it possible to serve a variety of different markets. Combined, the two companies will combine their strengths on a common platform to provide their customers with an expanded industrial offering in the future.

"We have little customer overlap and only two overlapping machining processes - metal cutting and electrical discharge machining (EDM). However, KPI is still new to EDM and has traditionally focused on machining and CNC metal processing, whereas at ACE the focus is much more on EDM. With this addition of EDM expertise, we can offer our customers significantly more capacity around wire EDM in tooling and prototyping for all the services we offer," explains Dave Holm, President at Kiski Precision Industries, adding, "Flexibility is the key to our success - from prototyping to high volume production, from complete machining to finishing, from plastics to special alloys and everything in that range."

More know-how for Aerotech

Aerotech also wants to benefit from the ACE acquisition, after all KPI now has additional capacities and more know-how in the individual business areas. The employees at ACE have been offered jobs at with KPI The ACE employees have been promised jobs at KPI, and the executives are also to be taken on.

"KPI has developed very specific know-how for key industries over the last few years and has also introduced special procedures and certifications. We can all only benefit from this knowledge - and it is a great advantage that KPI is only about 45 minutes by car from Pittsburgh, as the professional exchange can take place without compromise," says Simon Smith, looking forward to the whole thing.

Good forecasts in highly competitive markets

The management in Pittsburgh is also satisfied with the current development. "We can look positively into the future," says Dr Robert Novotnak, President of Aerotech. "Given current demand, these investments will help us continue to provide our customers with the products and services they expect from Aerotech." And Aerotech CEO Mark Botos emphasises, "Fully meeting our customers' needs has been a core part of our company philosophy for 50 years. We look forward to continuing to deliver on our ideas of quality and precision and succeeding together with our customers."

Aerotech GmbH

90768 Fürth

Germany