- Auszeichnung

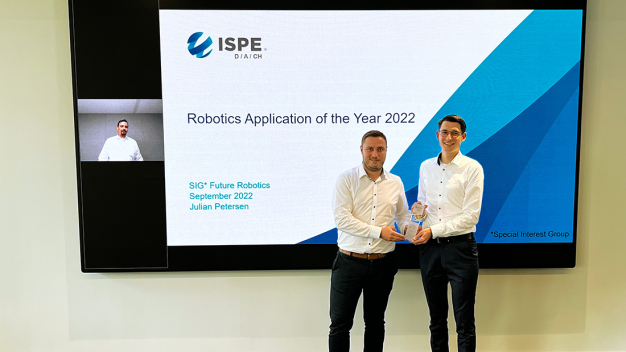

robocell was distinguished as the “Robotic Application of the Year”

The latest groninger line, the robocell, was named by the world’s largest non-profit organization in the pharmaceutical industry, ISPE “Robotics Application of the Year” today.

As soon as it got on the market, it already received an award—the latest groninger development – the robocell. The latest machine concept of the aseptic filling systems, which completely eliminates the human “risk factor” in pharmaceutical processing and takes into account the latest regulatory requirements of the industry (EU GMP Annex 1), has now been awarded the “Robotic Application of the Year” award. The prize was awarded for the first time this year as part of the ISPE workshop “SIG Future Robotics”.

The ISPE, “International Society for Pharmaceutical Engineering”, is the world’s largest non-profit organization in the pharmaceutical industry. It connects members of the pharmaceutical industry and encourages interdisciplinary exchange and knowledge transfer.

The top-class jury justified its decision at the award ceremony in Annecy le Vieux, France, on Thursday as follows: “On the one hand, the robots increase efficiency, while avoiding manual actions in the sterile production environment.” The built-in robots would take over tasks such as format changes at the push of a button and the automated installation of sterile parts, the jury went on to say. “Secondly, handling, waiting or changing gloves is avoided. And thirdly, the use of robots allows to reduce the size of the sterile room. This shortens decontamination cycles,” say the experts.

The fact that the filtered air flow was optimized in the machine concept so that the sterile filled liquids only come into contact with fresh air (first-air) created enthusiasm. “So far, this is absolutely unique and the robocell demonstrates and implements that for the first time.”

The groninger family business has relied on the use of flexible robotic solutions in its systems for many years, and has even developed and patented its own robocell modules.

Josef Veile, Technical Director of groninger & co. gmbh in Crailsheim, where the family business builds its filling and closing lines for the pharmaceutical industry, states the following: “We have the highest standards when it comes to our robot solutions, but also in terms of their application. They should not only be used to make pharmaceutical processing more efficient, but above all safer.”

Jens Groninger, Managing Partner of groninger, is thrilled about the award and adds: “This award confirms that we are on the right path. Together with our partners, we want to continue to actively shape this in the future and continue to set standards in the industry.”

robocell

The innovative system concept of robocell was created in cooperation with the Swiss partner company Skan—technology leader for isolators, clean room devices and decontamination processes.

“Our guiding principle when designing the robotic filling system was always the intelligent use of robotics and not the use of robotics for robotics’ sake,” explains Veile.

This principle made it possible for the two partner companies to develop and market a completely glove-free isolator filling system. “In addition to the regulatory requirements, we also intensively involved our customers, such as PSM GmbH in Schiffweiler, and asked actively for their feedback,” Groninger also describes.

The result is a line concept in which almost all work steps previously carried out by the operating personnel are replaced by custom-manufactured robots. There are no more glove ports. Human interventions in the core processes of the pharmaceutical filling process is a thing of the past.

Conveyor belts or conventional drives are also no longer installed, since cleaning them is sometimes poses to be difficult and the risk of possible product contamination is correspondingly increased. The transport of optionally pre-sterilized syringes, vials or cartridges is taken over by robots instead.

Pharmaceutical sales manager, Dirk Schuster, is pleased that the robocell not only impressed the ISPE jury, but also attracted a great deal of interest in the market: “The robocell technology has already been able to win over several well-known pharmacists due to its advantages and we at groninger have already placed a number of systems on the market.” Schuster also said that their portfolio has been expanded with the line in the small-batch sector. “As a result, we are able to offer our customers the complete performance range for the processing of pre-sterilized syringes, vials and cartridges, from the small-batch sector to the high-performance line.”

groninger & co. gmbh

74564 Crailsheim

Germany