- 3D printing

Layer by layer to more stability: New possibilities for 3D printing through integrated plasma treatment

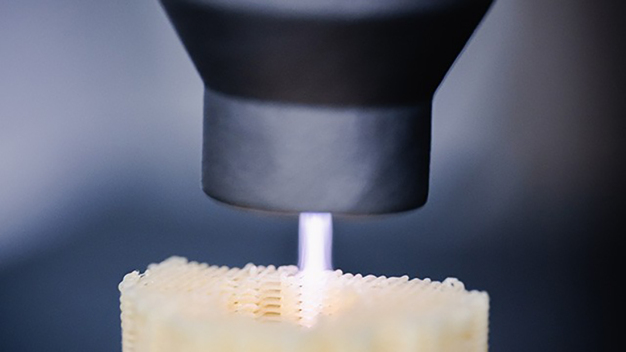

Additive-manufacturing processes are characterized by the fact that the components are built up layer by layer using, for example, plastics. The adhesion of the individual layers thereby plays an important role, as it significantly influences the stability of the printed components. At the Fraunhofer Institute for Surface Engineering and Thin Films IST, plasma sources are currently being developed which can be integrated into the 3D printer, thereby enabling a targeted chemical modification of the surface during the printing process itself. Amongst other things, a significant increase in adhesion can consequently be achieved, which leads to new options for 3D-printed component manufacturing.

With the aid of atmospheric-pressure plasmas, surfaces can be specifically pretreated, cleaned or functionalized. The configuration of the plasma sources is thereby variable and can be adapted according to the application: From pinpoint treatments of the smallest areas through to the handling of substrate surfaces several meters in size, anything is possible. Depending on the type of treatment, the most diverse functions can be achieved, such as control over the adhesion of coatings and paints, or adapted wettability. Through the combination of atmospheric-pressure plasma treatment and 3D printing, it also becomes possible to apply this enormous range of functions in the field of additive manufacturing, thereby opening up new fields of application for 3D printing. The application possibilities are manifold: from small-series production with integrated surface modification for subsequent processing steps such as metallization or bonding, through the production of more stable 3D-printed components, and on to the experimental utilization of the plasma sources. Possible applications include the automotive industry, the aerospace sector and medical technology.

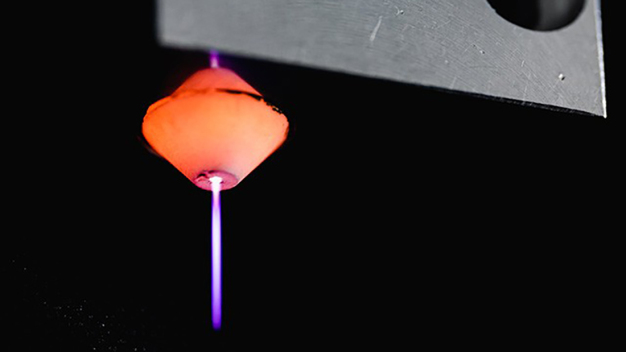

Currently, a so-called plasma point source is being deployed at the Fraunhofer IST. This allows the printed structures to be modified with high resolution on a comparatively small surface area. The special feature of this is that the source itself is small enough to be installed in a commercially available 3D printer. As a result, plasma treatment can take place immediately after deposition of the individual layers, without the necessity of major modifications. The long-term goal of the work is the integration of a plasma ring source, which is placed directly around the extrusion nozzle, and which consequently enables treatment to become a part of the printing process.

Fraunhofer-Institut für Schicht- und Oberflächentechnik IST

38108 Braunschweig

Germany