Minimum disturbance of the production process by the automatic Luftkeimmonitoringsystem asip

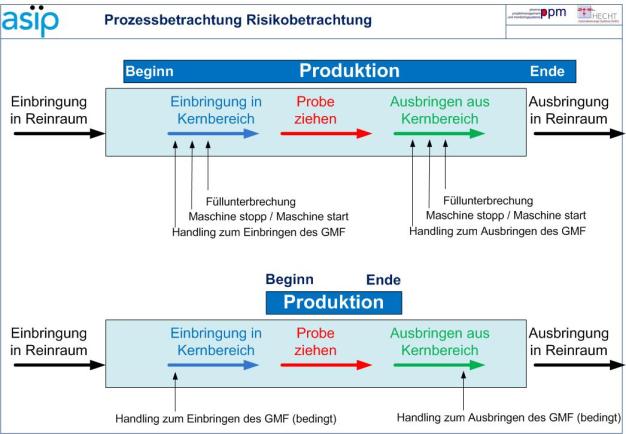

A semiautomatic measuring procedure like those the air germ measurement means� always a risk for the process which can be examined. With the Luftkeimmonitoringsystem asip these risks can be reduced to a controllable measure.�In order not to reduce the risk by ideal in and yield of the filter bodies, transferring procedures are built for example into the machine nuclear range. It does not play a role whether with RABS, insulator technology or conventional clean-room technology one works. �Since the decentralized measuring point distributor with its vacuum generator is outside of the pure area, no contamination risk, for example by impure exhaust air, goes out also with this. � With the conventional operational sequence of one� usually during production the measuring medium into the aseptischen nuclear range in and again one yields for active air germ measurement. As evident in the diagram 1, thereby the risks of the then necessary filling interruption develop, Maschinenstopp and � starts and the handling for in and yield measuringmedium due to the realizations for long-term measurement with GMF (source: Continuous Microbiological air monitoring for Aseptic Filling LINEs, PDA journal OF Pharmaceutical� Science and Technology VOL. 61, No. ) those developed 2, March/April 2007 pike automation GmbH as well as ppm the GmbH an automatic air germ measuring process, which minimizes the risks specified above clearly. By bringing the measuring media into the aseptischen nuclear range before the product in the respective pure space line, the risk of a contamination is crucially reduced. The measuring process cycle during production runs off automatically, a handling in the pure space line is not necessary. Are yielded the measuring media after the measurement only at the end of the respective production part run.�The Luftkeimmonitoringsystem asip supervises the correct fit and the function of the measuring medium during the measurement. Also personal errors of the measuring personnel are excluded by the automatic measuring process cycle. �Depending upon �User need can be individually developed the respective measuring procedure courses. Like that a maximum optimization of the measuring processes and thus a minimization of the production process risks are possible.��

This text was translated automatically.