- Lasertechnology

Process Chains for Isolation and Analysis: from Single Cells to Organoids

Researchers at the Fraunhofer Institute for Laser Technology ILT are working on new tools for the preparation and analysis of single cells and cell assemblies. The team developed the “Liftoscope,” a system for cell sorting for subsequent cultivation that can analyze and transfer biomaterials precisely and in a way that is gentle on cells. In addition to this system, further 3D bioprinting methods are increasingly finding their way into biotechnological research: Thanks to the development of microfluidic organ-on-a-chip systems, various cells can be arranged in a defined and reproducible manner to form artificial tissues. Fraunhofer ILT experts will be presenting the results of their research at analytica in Munich from June 21 - 24.

Future-oriented, biotechnological solutions and innovative laboratory technology await the approximately 35,000 visitors at analytica, with more than 700 exhibitors, the world's leading trade fair for laboratory technology, analytics and biotechnology. In the first edition since the beginning of the corona pandemic, Fraunhofer ILT will be present and exhibit several topics relevant to the future of medical technology.

Analyze, isolate, transfer

To produce cell cultures, a laboratory must follow many different steps in which the cells are grown and examined. Indeed, cell cultivation is very time-consuming and error-prone owing to the manual work involved in conventional processes. At analytica, Fraunhofer ILT is presenting two projects on cell cultivation: In the joint project "Liftoscope", Fraunhofer ILT is working with the Fraunhofer Institute for Production Technology IPT to develop a gentle, automated process for analyzing and isolating cells.

To accomplish this, the institutes use a high-speed microscope to scan a cell culture plate. Based on the image data, the cell morphology of the detected cells can be determined using a specially developed algorithm. To ensure that only suitable cell material is subsequently isolated, the researchers use laser-induced forward transfer, or LIFT for short: The cell cultures are located on the cell culture plate in a special hydrogel. A laser is focused into the gel very locally under the selected cells and generates a precisely tuned amount of thermal energy. The short pulse causes the gel to expand and transfer the cells to a cell culture support above, on which they are then further cultured.

The fully automated analysis and isolation process can be easily integrated into any laboratory environment. Thanks to its modular design, it is versatile and can be used in existing microscopes. A commercially available microtiter plate, for example, is suitable as a cell carrier. This makes the process not only time-saving, but also cost-effective.

Another challenge is the transfer of adherently growing cells: "Here we are still looking for the appropriate hydrogel to improve the survival rate of the cells," says Richard Lensing, scientist in the Biofabrication Group at Fraunhofer ILT. To make the process even more efficient, researchers at Fraunhofer IPT and ILT are also working on a faster and more sophisticated algorithm that can classify and select cells based on various characteristics.

Organ-on-a-Chip

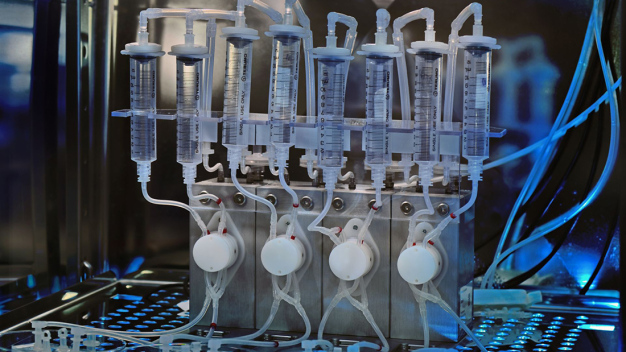

3D printing also provides the researchers with new opportunities: Bioprinting makes it possible to construct artificial tissues, helps society do without animal testing and improves therapy diagnostics. Fraunhofer ILT scientists will show several microfluidic organ-on-a-chip systems the size of a USB stick at analytica.

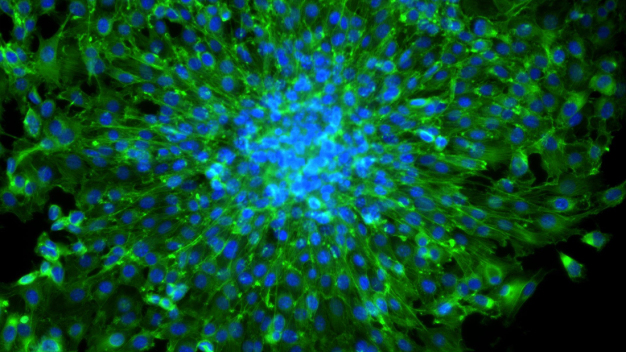

The aim of 3D bioprinting is to arrange cells in precisely defined and reproducible spatial configurations to form artificial tissues. Cell-laden hydrogels, so-called bioinks, are printed in an extrusion-based process. In such cultures, the cells develop approximately as they do in the body. At the same time, researchers can more easily intervene and observe the process. In combination with a microfluidic chip design, an organ-on-a-chip can be constructed from multiple cell types, which allow for easy analysis of cells. The tests can be precisely targeted and are expected to offer better and more accurate results when the effects of bacteria, viruses and drugs on in vitro tissues are studied.

Fraunhofer-Institut für Lasertechnik ILT

52074 Aachen

Germany