- Storage technology

N2 purging for wafer preservation

A large part of the air we breathe every day consists of nitrogen (N2). However, while the human body only uses the oxygen in the air, nitrogen is essential for some industries.

Unlike oxygen, nitrogen is a very inert gas with low humidity and is therefore ideal for the storage of sensitive goods, e.g. in the electronics and semiconductor industries.

The humidity contained in the air, but also oxygen, can cause damage to silicon wafers, for example. Therefore, a low-oxygen atmosphere is created there with the help of nitrogen, which prevents slow oxidation in the form of corrosion.

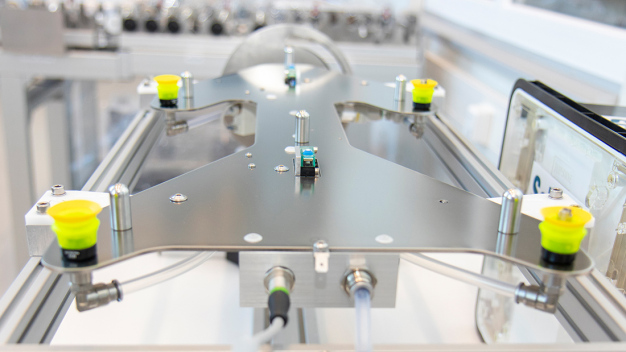

With its Purging Bay, the Schiller company offers a solution for wafer preservation during storage. Each storage place of the stocker (cleanroom storage system) can be equipped with this double-deep storage station. On the Purging Bay, two FOUP cassettes (containers for the wafers) can be stored one behind the other and purged with nitrogen. The Purging Bay was developed and designed by Schiller and can be used in the Schiller Linear Stocker or Max Stocker.

All 300 mm FOUP cassettes from well-known manufacturers that have an inlet and outlet valve on the underside can be stored on the Schiller Purging Bay. Kinematic coupling as well as a placement sensor on the top of the construction ensure precise placement of the cassettes.

All components of the purging bay, such as the inlet and outlet valves, the filter elements and the electronic components are mounted on the bottom side of the purging bay to save space. This results in a low overall height of only 50 mm. Depending on requirements, the purging time and the purging interval can be defined customer-specifically via Schiller's SWarePro warehouse management software.

The purging bay is already being used in various projects with several thousand storage places. Each bay is subjected to a complete function test of the mechanical and electrical components in Schiller's in-house clean room before delivery.

SCIO Automation Intrasolutions GmbH

94486 Osterhofen

Germany