- People

Father of the Cleanroom

Willis Whitfield

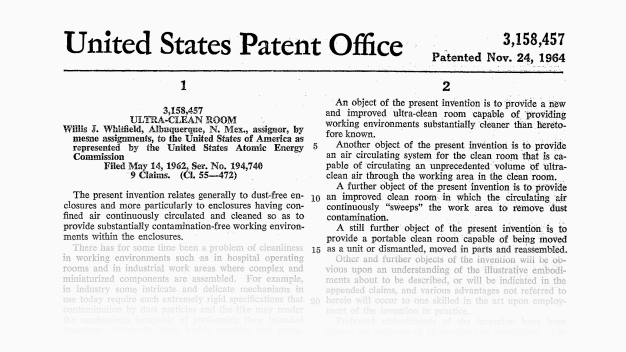

In 1962, Sandia National Laboratories in Albuquerque, New Mexico, obtained a patent for the “Ultra - Cleanroom,” which had been invented earlier by Willis Whitfield, one of the engineers working for the national security laboratory. This event helped to spur on technological developments including modern semiconductor production which, at the time, had not even been envisioned yet.

“As a child, I didn’t really know what it was my father had invented. I was just six or seven years old,” recalls Jim Whitfield, who – like his father – became an engineer. “I don’t even think he realized just how important the cleanroom he had invented would become.”

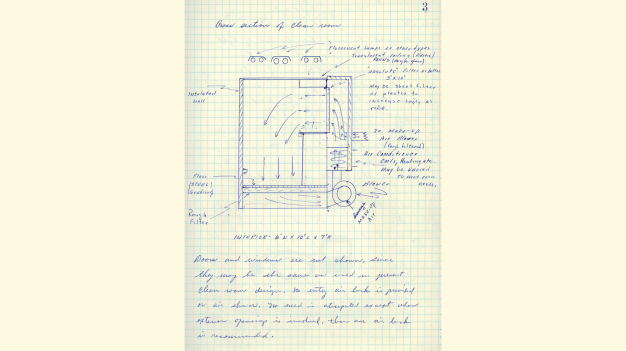

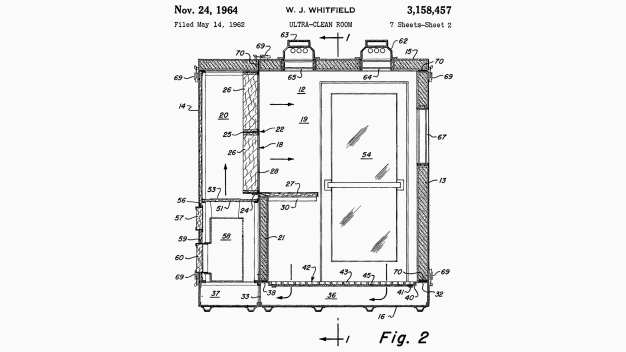

Up to the day on which Willis Whitfield received the assignment to develop an improved solution for keeping contaminants out of laboratories, only turbulent cleanrooms existed; these were basically air - conditioned rooms in which the air swirled around. “He took a look at them and came up with the solution right away. It’s simple if you use laminar airflow that comes from the ceiling and flows out the floor, he said to himself. It didn’t take him five minutes to get the idea,” explains Jim Whitfield. After that, the plan was implemented, meaning that a prototype measuring eight by ten feet (about 2.5 by 3.3 meters) was built and tested: it made it possible to exchange the air about 600 times an hour. “The tests were done with smoke, in order to see the airflow in the room.” This was back in 1961, although the first patent application was not filed until a year later. By April 1962, Time Magazine had already published a story with the title “Mr. Clean.” The Whitfield Ultra-cleanroom was a groundbreaking innovation. The air in the cleanroom was 100 times more pure than anything before. A photo from 1962 shows Whitfield next to his invention, speaking to the people in the cleanroom on an integrated telephone.

“Then Sandia quickly registered the patent – not my father. No telling how wealthy we’d be today, if he would have gotten it,” says Jim Whitfield with a grin. But money didn’t matter much to his father. “It’s good to have enough

of it, but enough is enough. He was proud of what he had accomplished. That was his attitude.”

Willis Whitfield was born in Rosedale, Oklahoma, in 1920 and grew up on a farm. “My grandparents had a homestead – land made available by the government.” In 1863, the Homestead Act was passed by the U.S. government. Under the law anyone who was at least 21 years old could get about 65 hectares of unsettled land. After five years, they got title to the land. “Our family planted cotton there. My father was used to pitching in everywhere.” The young Willis Whitfield studied physics and joined the Navy in 1944, where he was assigned as a specialist for Aircraft Experimental Systems at the Naval Proving Grounds at Dahlgren, Virginia. Then, in 1954, the physicist came to Sandia National Laboratories in Albuquerque, New Mexico, where nuclear weapons were being designed in the 1950s. “It was all top secret, which is why he never told us anything, but I know that he developed a whole series of warheads,” says Jim Whitfield.

His father was a real scientist, a man of many interests, who liked to get to the bottom of things. “At Sandia, they also experimented with all kinds of different explosives, which were ignited in steel barrels to avoid damage. Of course, the detonations were so enormous that they tore the barrels apart. As a result, they went out into the desert, which was quite an operation. Well, my father heard about all this and told them they should create a vacuum in the barrels – then they wouldn’t burst anymore. When they tried that out, they initially thought that the explosives had not ignited because it seemed like nothing had happened, especially since they hadn’t heard anything. But when they opened the barrels, they saw the signs of the explosions on the inside. In a vacuum, of course, there is no transmission of sound.”

In addition to the cleanroom, Willis Whitfield also developed a workstation with laminar flow. Five years after his groundbreaking invention, he worked in a project group at Sandia that did research for NASA. “There, the components for the space program were initially still being assembled in a non - clean environment,” says Jim Whitfield – who, as a child, considered the Albuquerque airport as his second home. “We went there so often to pick up my father. He was always on the go.” Until 1976, Willis Whitfield worked on projects for NASA. And from 1977 until he retired in 1984, he was back in the area of nuclear research.

In a hospital in Albuquerque, Whitfield’s cleanroom principle was used in an operating room for the first time in the 1960s. He also gave lectures on the topic of the cleanroom at the University of New Mexico. One day his son Jim, who was studying electrical technology at the time, was also in the audience. “I slipped in unnoticed and listened to him,” says the computer scientist, who had a very close relationship with his father. “He had the gift of motivating other people and helping them move ahead. He was a quiet, affable man, who was friends with many of his colleagues and coworkers. I’m sure he was a good boss. Many of his colleagues still met regularly with him after he retired. I’m glad that my father had such a long and fulfilled life.”

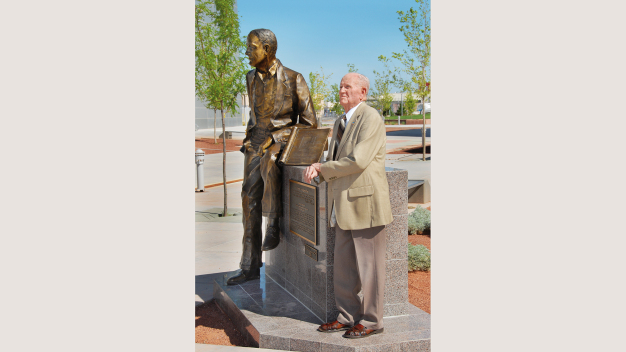

In 2007, Sandia Laboratories – for which he had worked for 30 years – gave Willis Whitfield a special honor. A bronze statue of him was unveiled at the facility in Albuquerque. It was created by Neal McEwen, who also worked for Sandia. At the base of the statue, next to the list of Willis Whitfield’s inventions, there is a quote from President Dwight D. Eisenhower: “ Engineers build for the future, not merely for the needs of men, but for their dreams as well. Thus, inherently, the engineer’s work is a fearless optimism that life will go forward, and that the future is worth working for.”

Exyte Technology GmbH

71272 Renningen

Germany