formnext connect: Arburg presents the special capabilities of the Freeformer

- Arburg Plastic Freeforming: Predestined for medical technology, soft materials and PP

- Freeformer: Integration into customer portal arburgXworld

- Broad spectrum: Challenging functional parts made of original plastics

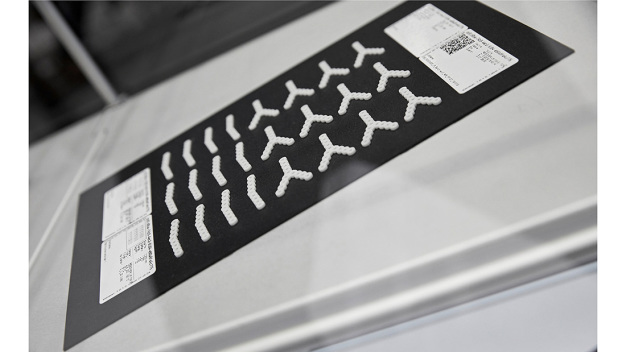

When it comes to demanding AM parts, the Freeformer is in its element. The Arburg Plastic Freeforming (APF) process with the Freeformer is predestined for medical technology, the processing of soft materials and PP, as well as for the additive manufacturing of multi-component parts. High-temperature plastics can also be processed using the open system. All these special capabilities are shown by Arburg during the formnext connect 2020, also in three expert presentations. In addition, Arburg presents the integration of the Freeformer into the digital customer portal arburgXworld as special titbit.

The Freeformer in sizes 200-3X and 300-3X process plastic granulates of the kind also used in injection moulding. This makes the open systems very economical and also enables a big variety of materials to be used. This also makes it possible to process bio-compatible, absorbable and sterilisable as well as FDA-approved original materials to be used. This in turn opens the door to new possibilities, also for human applications.

AKF for all kinds of implant

“In medical technology, we can also accomplish very demanding applications with the AKF process that other processes simply cannot handle”, explains Lukas Pawelczyk, Head of Freeformer Sales at Arburg. As an example, he names absorbable implants. As well as Resomer Composite LR 706 S ß-TCP, a product similar to human bone that promotes bone formation, the Freeformer was recently used to process another innovative material from Evonik: The polymer from the Resomer-C family is used in the soft tissue sector.

Great variety of materials

With the additive AKF process, it is possible to produce parts from soft materials in virtually all Shore hardnesses.

In relation to mechanical load-bearing capacity, recoil characteristics, UV stability and endurance strength, these parts share almost the same properties as injection moulded parts. With the slicing parameters, various material densities can be achieved within a part.

“Completely functional prototypes made of soft thermoplastic elastomers are mainly in demand in the automotive industry“, explains Lukas Pawelczyk. During the digital event in Frankfurt, Arburg does not only present automotive parts but also shows the production of a flexible shoe sole and, as an impressive example of multi-component injection moulding, the production of a functional part made of semi-crystalline PP and flexible TPE as a classic hard/soft-combination. The production of medical and technical parts from high-temperature plastics rounds off the spectrum.

Integration into the customer portal arburgXworld

Arburg is not only focussing on the production of an AM part but the additive manufacturing is also considered a process that has to be integrated into the whole production environment of the companies. In this context, the successful and continuous process monitoring and documentation plays a decisive role. During the formnext connect, Arburg therefore shows the integration of the Freeformer into the customer portal arburgXworld and the retraceable documentation of process data.

ARBURG GmbH + Co KG

72290 Loßburg

Germany