Fronius welds prototypes for suppliers

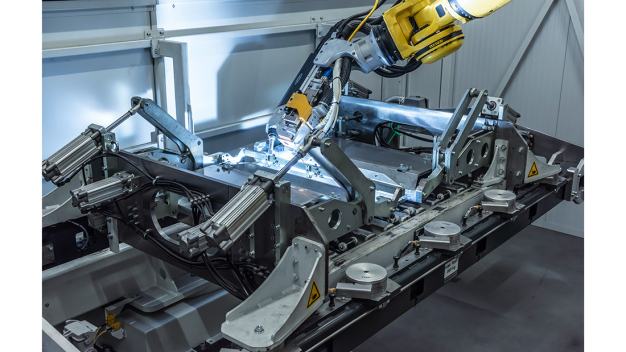

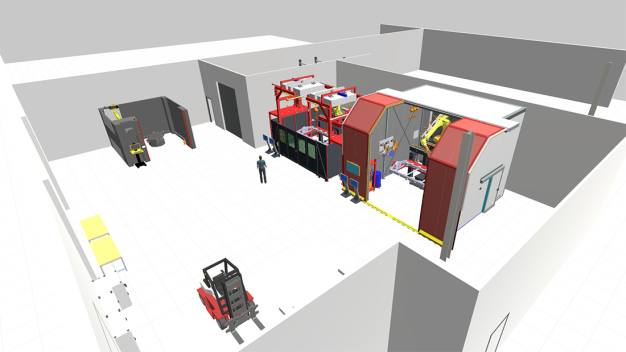

In late autumn 2020, the new prototyping centre from Fronius International will be put into operation. At the site in Wels, Upper Austria, the welding technology manufacturer will not only be working on individual solutions for customers in the field of joining technology, but also welding small series components for the prototype phase.

Trends such as e-mobility are resulting in new components and thus new challenges in production, for example when it comes to specific knowledge in joining technology. The special systems that are required, particularly for prototype manufacturing, can pose an investment risk. “When working with suppliers over the past few years, we have discovered that the construction of prototypes is an important topic that comes with a degree of uncertainty for our customers. For this reason, we have decided to support them in this regard,” explains Harald Scherleitner, head of sales in the Fronius Business Unit Perfect Welding.

As an important strategic step towards becoming a solutions provider, in the future Fronius Perfect Welding will be welding components for prototypes according to customer requirements. This means the customer does not need to invest in their own prototyping centres and also has the welding knowledge of Fronius at their disposal. Wolfgang Scherleitner, head of the prototyping centre, continues: “We offer our customers technical support and develop the ideal welding solution for the specific component in house. If this eventually goes into series production, as a general contractor we can also supply the necessary welding systems.” The Fronius prototyping centre will be put into operation at the start of November this year.

Fronius International GmbH

4643 Pettenbach

Austria