Component check: the perfect position for top quality cleaning

Libelle Product Control from BvL detects position deviations

With a new product from the intelligent cleaning portfolio, BvL Oberflächentechnik GmbH offers new options for component control: Libelle Product Control generates photographs and stores these for various applications. Initially, the “Position Monitoring” application monitors the feeding and alignment of the components to be cleaned. The new product will be presented for the first time at Parts2Clean in October.

Reliable, thorough parts cleaning plays a crucial role in production processes across all industries. The more precisely the nozzles are directed at the component to be cleaned, the more efficient cleaning is possible. Precise loading of the workpiece holders is particularly important for components with complex geometries. Even undercuts, edges and very small holes then no longer impede thorough cleaning.

Exact component detection regarding number and position

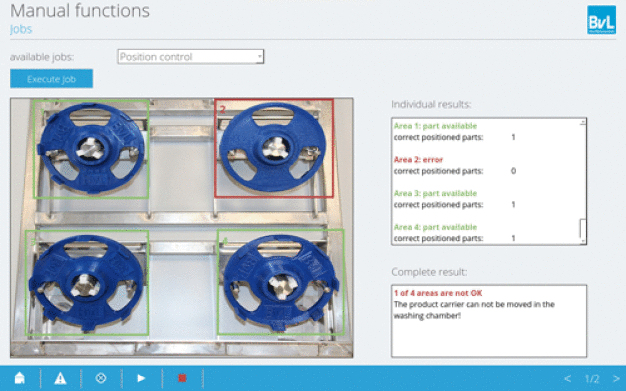

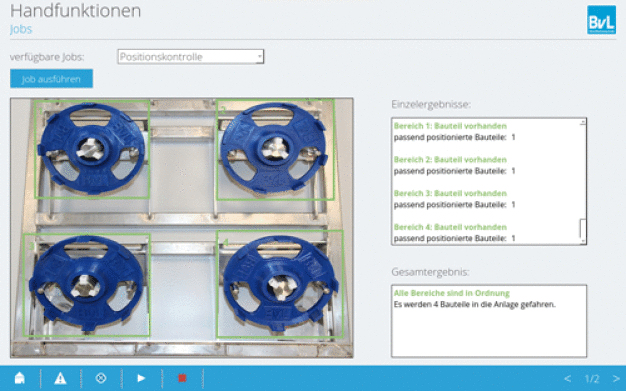

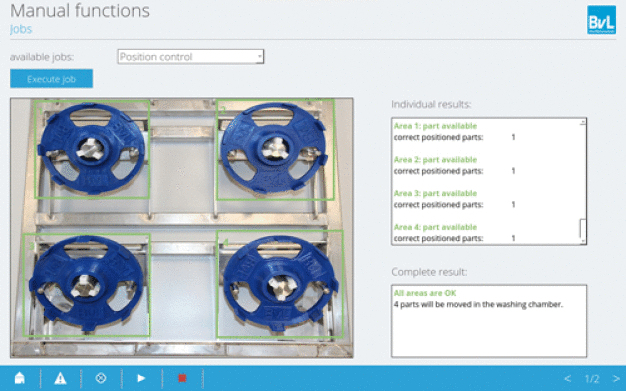

With an addition to the sensor system product line under the name of Libelle Product Control, the cleaning system manufacturer BvL Oberflächentechnik provides an essential prerequisite for a perfect cleaning process. With the help of the “Position Monitoring” app, the system counts and checks the elements to be cleaned. This allows Libelle Product Control to detect the number of loaded components and their position. If a component is missing or was placed in the workpiece holder slightly offset, the sensor system signals the corresponding information to allow correction.

Detailed integration of individual requirements

Libelle Product Control can be integrated into a Yukon continuous system or Niagara basket washing system, for example. During customised manufacturing of the respective cleaning system, detailed photographs are already taken of the respective component as part of the teaching process. The ambient conditions are just as important for the function as the individual customer requirements regarding output of the results and control of the cleaning system, adapted to the existing cleaning process.

Further development options for Libelle Product Control

In addition to the currently available “Position Monitoring” application, the technical options of Libelle Product Control allow additional applications which are currently undergoing intensive further development at BvL. This is always driven by the objective of continuously increasing the quality and process reliability of parts cleaning.

Participation at the Parts2Clean trade fair

During the trade fair Parts2Clean in Stuttgart from 22nd-24th October 2019, BvL will present the new product Libelle Product Control with its application possibilities in Hall 9, Stand D13.

BvL Oberflächentechnik GmbH

48488 Emsbüren

Germany