Vector kinematics

A new dimension of dynamic cleaning

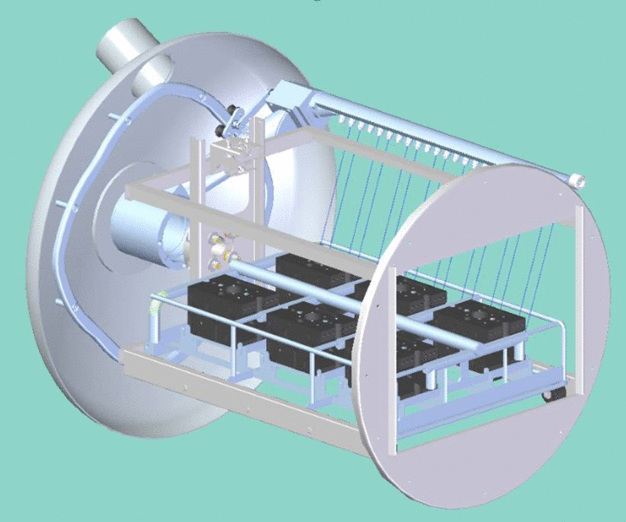

MAFAC cleaning machines set global standards in terms of cleaning quality, efficiency and application diversity. The patented process technology of counter- or co-rotating movements of spraying system and basket receptacle system is a crucial component of this corporate success. MAFAC has further developed this kinematic system approach and presents the patented MAFAC vector kinematics, an extended cleaning process that provides even more movement and thus faster cleaning and drying.

MAFAC vector kinematics - more movement and greater effectiveness

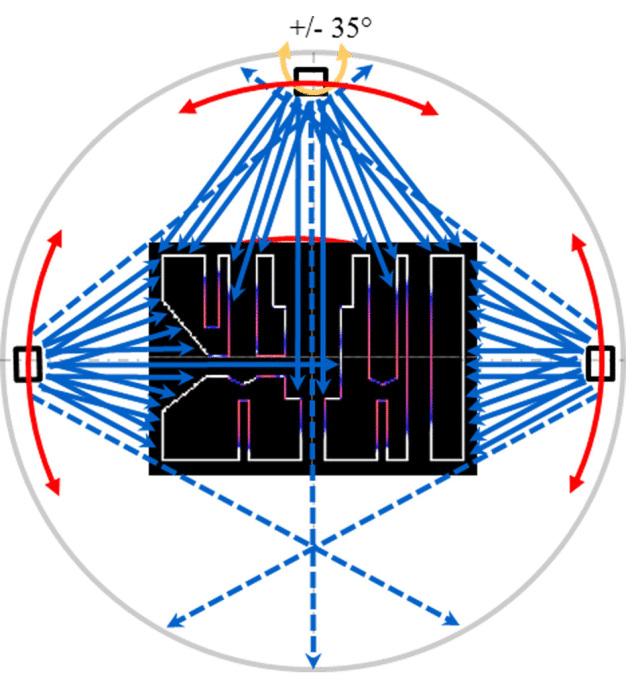

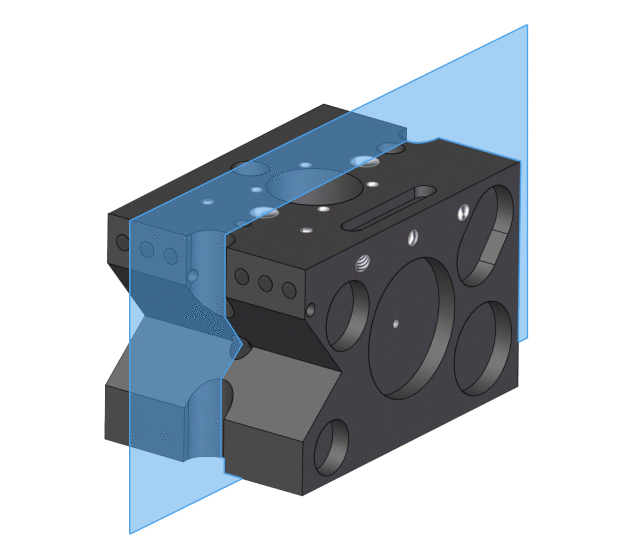

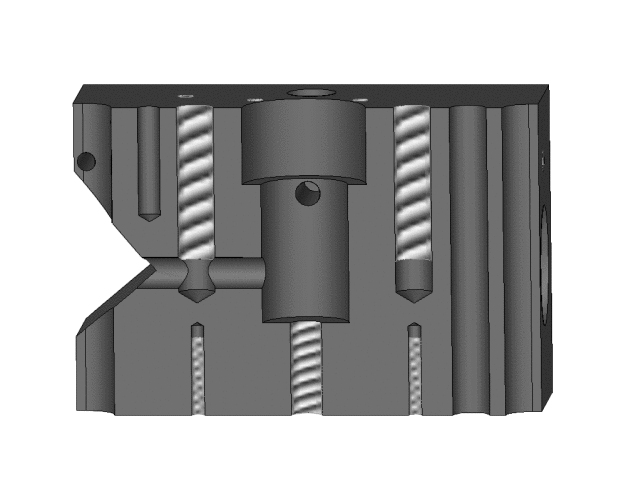

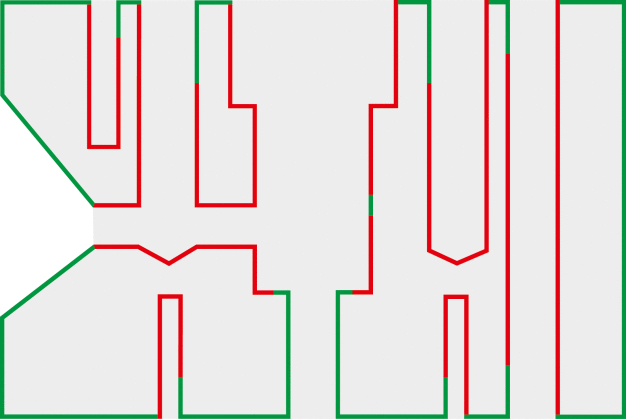

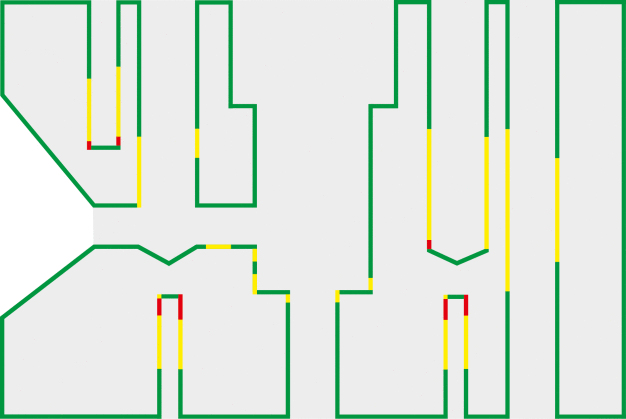

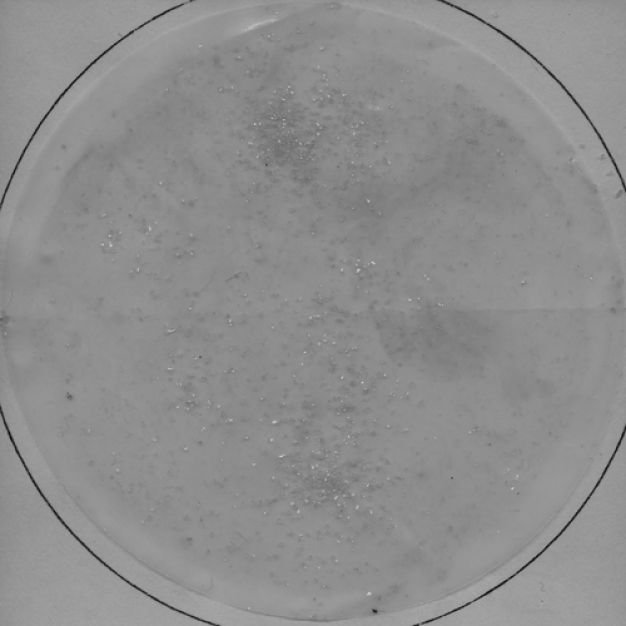

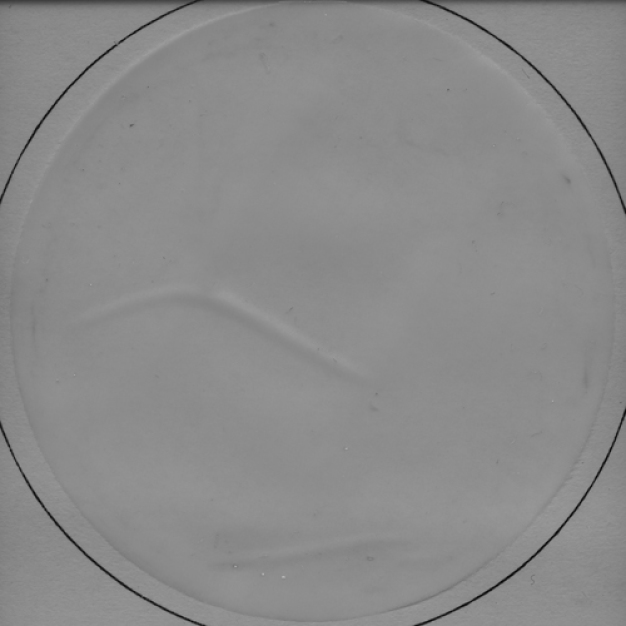

In contrast to the process in a rigid nozzle system, the workpieces are not hit at one specific but from many different angles. The nozzle tube performs both a rotating and a rocking movement. The rocking movement is performed around its own axis by 35° to either side – the basket receptacle system rotates synchronously at an optimally adapted speed. The Maviatic controller of the machines calculates the movement of the basket rotation beforehand, whereby co- and counter-rotation are both possible. Real impact tests showed that this coordinated interaction of nozzle tube and basket movement achieves a considerably more effective impact on the part to be cleaned. Compared to rigid systems, the particle quantity is reduced by up to 70 % while the cycle time remains the same. This means that, in relation to Sinner's circle, vector kinematics leads to a better cleaning result in the same time or to the same result in a shorter time due to the larger mechanical part.

Innovative technology for more flexibility

In particular, manufacturers of complex workpieces with geometries and surfaces that can be reached in different ways benefit from this innovative process. The various angles of impact lead to significantly less spray shadows, so that excessive cleaning of easily accessible component regions with valuable resources is avoided. The entire cleaning process is more efficient and more economical as undercuts and blind holes are already reached during spray-cleaning. Previously, this was only possible in the flooding process. In the future, users will also be able to react with significantly greater flexibility to a wide range of parts or to changes in the part program: Thanks to the high angle variance, a large variety of significantly different workpiece batches can be processed - from standard operation to sophisticated and varied angular application. The new MAFAC vector kinematics permits an effective execution of many cleaning tasks.

The new process can be integrated as an option in the MAFAC JAVA and MAFAC PALMA machine types, without any further adjustments.

MAFAC – E. Schwarz GmbH & Co. KG

72275 Alpirsbach

Germany