Manufacturing and commercialisation of components for high purity stainless steel tube systems

Assurance of quality even for welds created by the customers

Weldability as significant product feature

As manufacturer of components for high quality stainless steel tube systems the family-owned German company Dockweiler has got a worldwide leading position in the field of tubing for semiconductor, pharmaceutical, biotechnological, and photovoltaic applications. A major proportion of the manufactured products has to be assembled from individual parts which must be joined by welding, so welding competence is a vital objective of its corporate philosophy.

Like other companies which depend on the soundness of their welding technology Dockweiler has implemented a system of efficient quality assurance procedures, but additionally to its proper joining activities it is primordial for this manufacturer to care about an at least sufficient quality level of the welds created by their customers.

No matter whether components with simple geometries like tubes, elbows, T-pieces, reducers or caps are demanded or complex units, e.g. manifolds or valves, have to be supplied, all of them are designed to become an integral part of a tube system for the distribution of high purity liquid and gas media at a high-tech production site.

Comprehensive inspection of incoming shipments

At Dockweiler’s a comprehensive inspection for all ingoing shipments is obligatory. Semi-finished products are only accepted if accompanied by valid in-shop testing certificates, the chemical composition of the materials is analyzed in a systematic manner and must comply with the standards or agreed limits, the geometry of the parts must not exceed the specified tolerances, and the mechanical properties and corrosion resistance must meet at least the expected values.

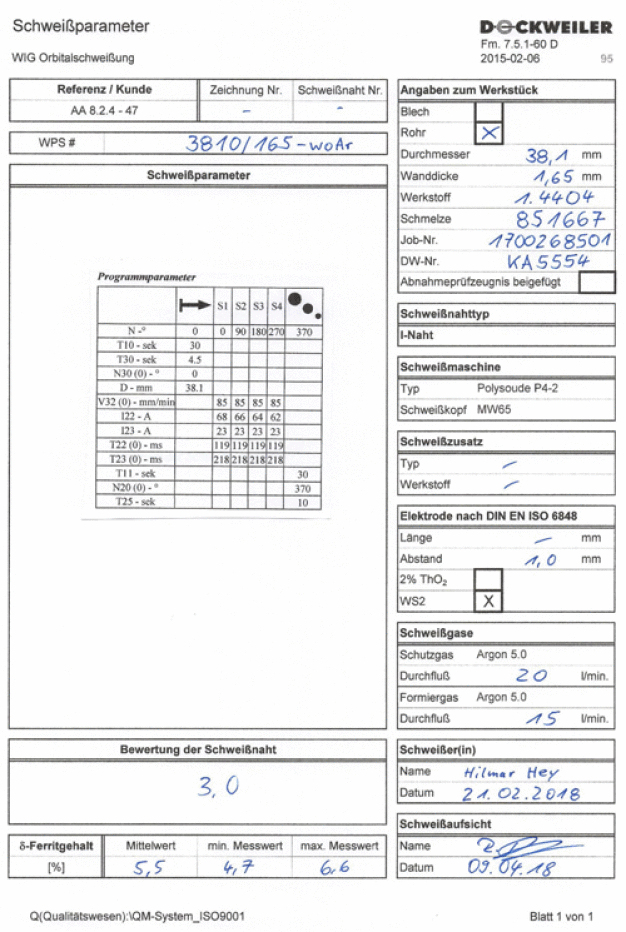

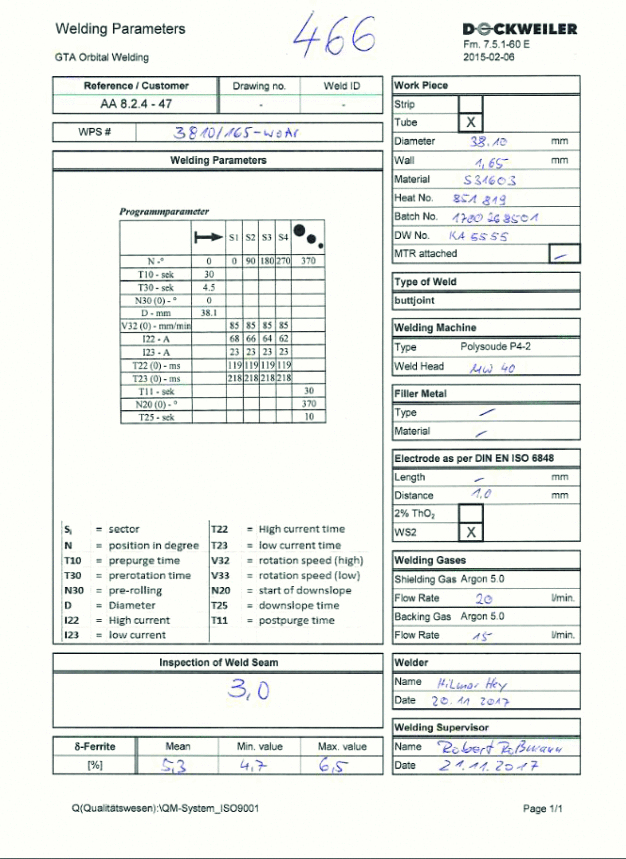

All parts which have passed these tests successfully are then reviewed for their weldability. After a visual examination of a few preliminary welds the experts are generally able to ascertain the parameters which have to be programmed for orbital welding of test coupons. The welds of these coupons are analyzed thoroughly: general visual impression of the weld seam, geometry at the inside and outside on the entire circumference of the specimen, surface appearance, presence of discoloration etc. Furthermore, cross-sections of the welded tubes are prepared for macrographic exploration: uniform and satisfying penetration in all positions, dimension of the heat affected zone, tendency to form coarse grains, and possible occurrence of segregation. Completed by determinations of the mechanical properties of the welded zones and their corrosion resistance the results are used for a final improvement of the welding parameters. Differently to the joining of tubes or pipes with more important diameters the arc time of these small parts is quite short and a possible increase of the welding speed would not cause substantial economic advantages, so the optimization can be concentrated exclusively on the tangible quality of the welds. An example of a completed form indicating the resulting welding parameters for a particular heat and batch of a certain material is shown in Fig. 2.

Internal specifications merge the most stringent requirements

Now it can be checked whether some or even all of the input materials qualify for Dockweiler’s in-house regulations. These regulations are laid down exclusively for internal use and consist of a compilation of the most stringent requirements of all applicable codes and standards. Components which are manufactured in accordance with these regulations can be supplied to any customer, independently of the specific codes which have to be respected in the particular case.

Otherwise, the materials are ranked according to a more extensive system within a range of marks from 1 to 5. Based on this ranking the best subsequent use for each of the batches is decided. Due to their individual properties some batches may suit better for pharmaceutical purposes, whereas others fit perhaps perfectly for semiconductor processing. According to Dockweiler’s experience a classification of 3 or better is absolutely necessary if the parts shall be provided for semiconductor applications.

Sophisticated welding technique

The proper material quality and geometry of the workpieces to be joined are essential prerequisites to obtain best welding results, but the process, the equipment, the consumables, the environmental conditions etc. must meet the same strict requirements.

TIG welding is probably the best choice if delicate materials like stainless steel or nickel base alloys have to be joined. No fumes or spatter are generated by the process, the welds are smooth and uniform and the welding parameters can be optimized within a wide range to preserve the required characteristics of the sensitive base materials.

As every welder knows, joining of thin-walled tubes with small diameters by manual TIG welding always turns out to be a tedious task. Only well-trained and highly-motivated staff members with extraordinary skills are able to obtain the expected results; the lack of reproducibility and the extremely low productivity are some of the reasons why this method is avoided whenever possible.

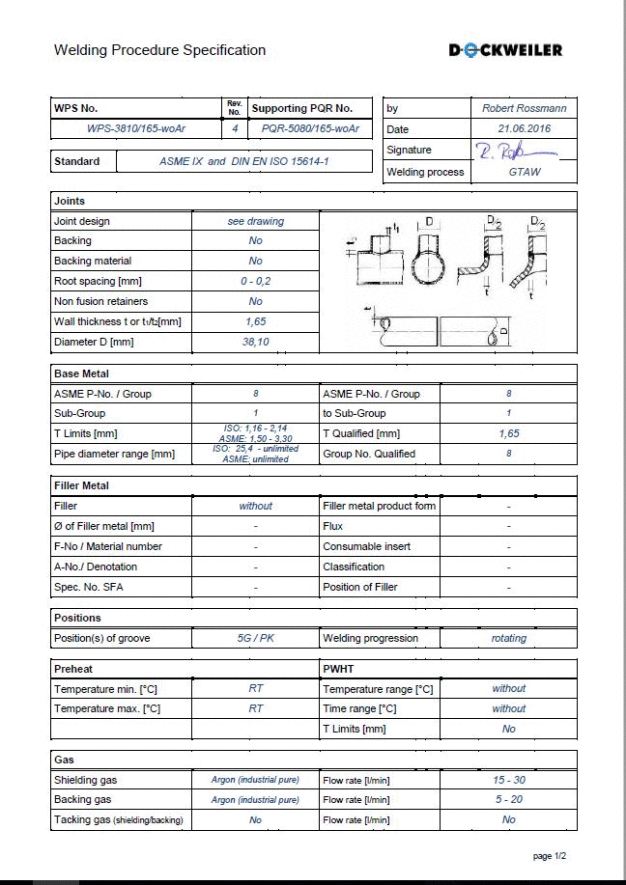

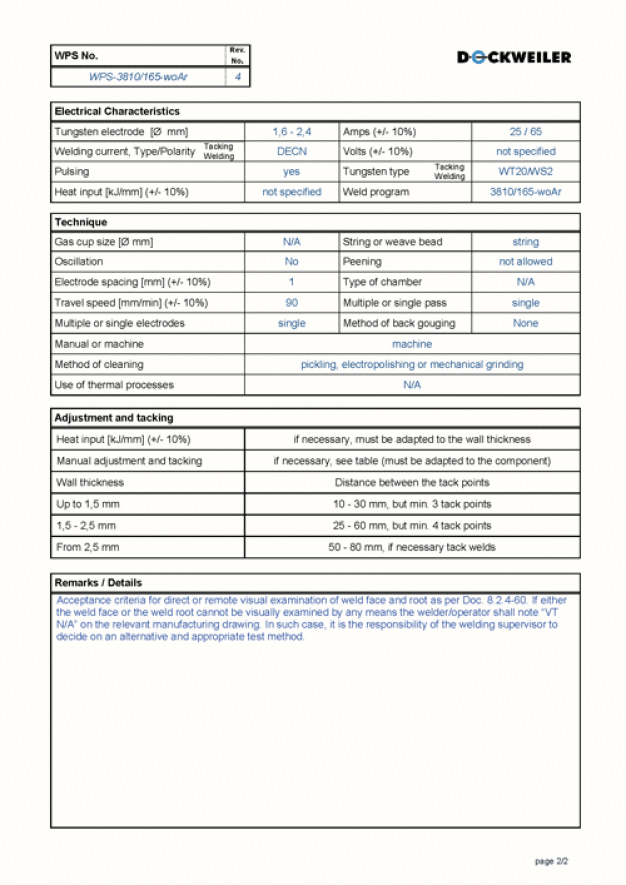

Orbital TIG welding of tubes is an efficient way to gain productivity and to improve the quality of the obtained welds substantially. The TIG torch travels around the circumference of the tubes to be joined, guided by a mechanical system. The optimized welding parameters are programmed in advance and stored in the memory of the control device. Generally, the operator follows the instructions of the particular Welding Procedure Specification (a completed WPS for the assembly of a T-piece is shown in Fig. 3) of the respective component. When it comes to the joining process, he has to position the orbital welding head on the workpiece and start the welding cycle. The weld itself is carried out automatically without any need for the operator to intervene; after the end of the cycle it is up to him to release the properly joined workpiece.

Thin-walled tubes can be joined by autogenous welding, i.e. the welds are completed without wire addition solely by melting and unifying the base material of both tube ends. This task can be accomplished perfectly by means of a closed orbital welding head as shown in Fig. 4. The entire welding zone remains inside the closed chamber of the welding head. Before, during, and after the welding operation the chamber is flooded with shielding gas, thus an accurate protection of the hot metal can be obtained. The torch is reduced to a tungsten electrode which is directly fixed on a gear inside the chamber and rotates around the tubes.

Acceptable welding equipment for clean room fabrication

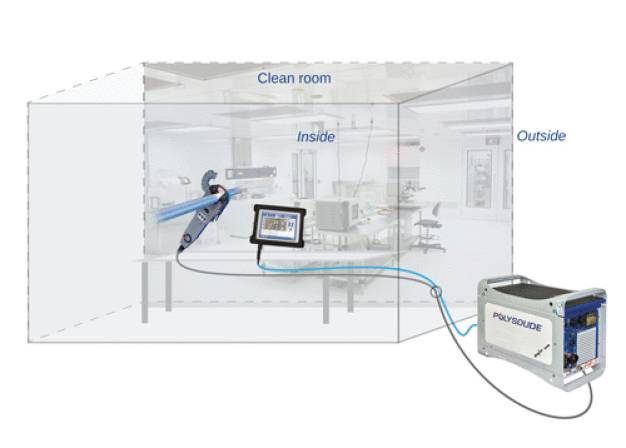

To obtain the requested quality, Dockweiler’s components for high purity applications are joined in a clean room environment as shown in Fig. 1. The atmosphere in such a clean room is controlled, i.e. the amount and size of floating particles are limited to specified values. A continuous flow of filtered air leaves the outlets under the ceiling and passes the clean room as laminar stream. Light particles are taken away by the stream and disappear together with the discharged air.

Human beings constitute an important source of particle emission in a clean room environment, therefore their skin and hair have to be covered as much as possible, and additionally they are instructed to move slowly. Many technical devices are banned from the inside of a clean room for the same reasons, especially if they disturb the laminar flow by hot surfaces or fans with powerful air streams.

However, closed orbital welding heads are tolerated in clean rooms. Generally, an electric arc has always to be regarded as efficient particle generator, but in this case the released particles remain enclosed within the chamber of the welding head and can not contaminate the surrounding atmosphere.

Power sources for TIG welding generate waste heat which is dissipated by strong fans, so they are not at all acceptable within a clean room environment. On the occasion of a change of the welding equipment in Dockweiler’s production line the French company Polysoude supplied power sources of the P4 family which have been especially adapted for this type of clean room application. The power source itself has been separated from the rest of the welding equipment and moved into the service area outside the border of the clean environment, only the operating panel and the closed welding head (Fig. 5) remain in the clean room.

The surfaces of the control panel with the integrated display are flat and easy to clean, no mechanical switches or other moving parts allow dust and dirt to be accumulated. Wearing of protective clothing presents no problem for the staff, as the soft buttons on the touch screen can be operated even with gloves. A graphic interface is used to indicate the progress of the current welding cycle, all important welding data is continuously monitored by a real-time data acquisition system.

Programmable and non-programmable welding parameters

A finished weld is always the result of a vast number of influencing factors. Generally, these factors are referred to as welding parameters. When it comes to orbital TIG welding Dockweiler’s experts talk about a total of several thousand parameters which contribute in a more or less important manner to a successful welding operation.

Some of the welding parameters affect the joining process so obviously that their setting is always carried out as a matter of course. In case of manual welding the operators are used to adjust or check these parameters routinely by means of the control elements of the power source, when automated TIG welding is applied the parameters have to be determined in advance and stored as a welding program. The corresponding parameters are also recognized as programmable welding parameters.

Within a typical program of an orbital welding cycle the following steps and their related parameters are specified:

- Pregas: Duration of flooding and purging the chamber of the closed welding head with shielding gas before the ignition of the arc.

- Ignition: Commonly carried out by a high frequency discharge.

- Welding current: As welding current serves usually pulsed DC, so the pulse time as well as peak and background current intensities have to be determined.

- Rotation: The linear welding speed is associated to the programmed rotational speed and the tube diameter.

- Sectors: To compensate the dissimilar influence of gravity in the different welding positions and the increasing temperature of the workpiece during the progress of the weld cycle, the creation of sectors may be useful. In a new sector a reduction of energy input can be achieved e.g. by an extended time span of the lower background current.

- Downslope: To avoid crater formation or cracks due to an abrupt turn off of the welding current the slowly decreasing current intensity at the end of the weld seam is known as downslope.

- Postgas: Duration of flooding the chamber of the closed welding head with shielding gas after the loss of the arc.

After a pertinent set-up of the welding equipment the programmed welding cycle can be executed as scheduled. The set-up of the equipment comprises its connection to the electrical power, shielding and backing gas supplies; the tungsten electrode to be mounted must consist of the specified alloy and have the proper geometry and exact length; and the clamping inserts of the welding head must match with the O.D. of the tubes to be welded.

Once the equipment is switched on the power source needs some time to warm up for an accurate control of the welding current intensities; shielding and backing gas flow have to be adjusted manually and a sufficient interval has to pass for the hoses and valves to be purged from humidity and oxygen. A reasonable number of test welds should be carried out to heat up the welding head and ensure that any remaining impurities can disappear from the inside of the device.

Now the equipment is ready and the production welds can be executed.

In summary, the set-up of orbital welding equipment is a rather complex procedure. The programmable parameters and their values are stipulated in the welding program, whereas the instructions for putting the devices into operation and adjusting or checking the rest of the remaining non-programmable parameters should be documented as precise as possible in the WPS.

Orbital welding in the factory or on site

Automated welding equipment is designed to repeat a programmed welding cycle as often as desired. A good welding result is reproducible as long as the surrounding conditions can be kept sufficiently constant. Dockweiler’s experts profit from their excellent knowledge of the welding production line in the factory and care thoroughly to avoid any deliberately caused modifications or changes. Additionally mounted devices support a constantly high quality level of the produced welds: a drying and cleaning unit prior to the consumption point improves the purity of the supplied shielding and backing gas substantially; a measuring instrument indicates the remaining oxygen content of the backing gas at the outlet vent, so the purging efficiency can be assessed and any waste of gas and time can be prevented.

Finally it’s not surprising that as a result of these efforts a constantly high quality level of the produced welds can be preserved. But, as mentioned in the beginning, up to now only half of the expert’s mission has been accomplished.

To accomplish their task, the experts are challenged to make certain that Dockweiler’s components are welded perfectly by the customers as well.

Arc welding on a construction site is always a difficult endeavour. Differently to a production line in a factory a lot of conditions can not or rarely be controlled. The only available electrical power supply is often interrupted, instable or with a too much shifted phase angle. Environmental conditions may be subject to strong fluctuations, differences in temperature and high atmospheric humidity can cause detrimental effects to equipment and consumables, sufficient protection against dirt and dust is not always possible.

As consequence of such unsatisfactory situations the whole range of weld defects can occur: lacking or excessive fusion, inadmissible weld seam geometry, porosity and heat tint, just to name some of them. Unnecessary to mention that due to those defects the mechanical characteristics and the corrosion resistance of the joints become irrecoverably corrupted.

But poor welding results of the customers can also have other causes: wrong set-up or unprofessional handling of the equipment, error in the welding program, inferior quality of tubes and/or consumables, defective equipment, etc.

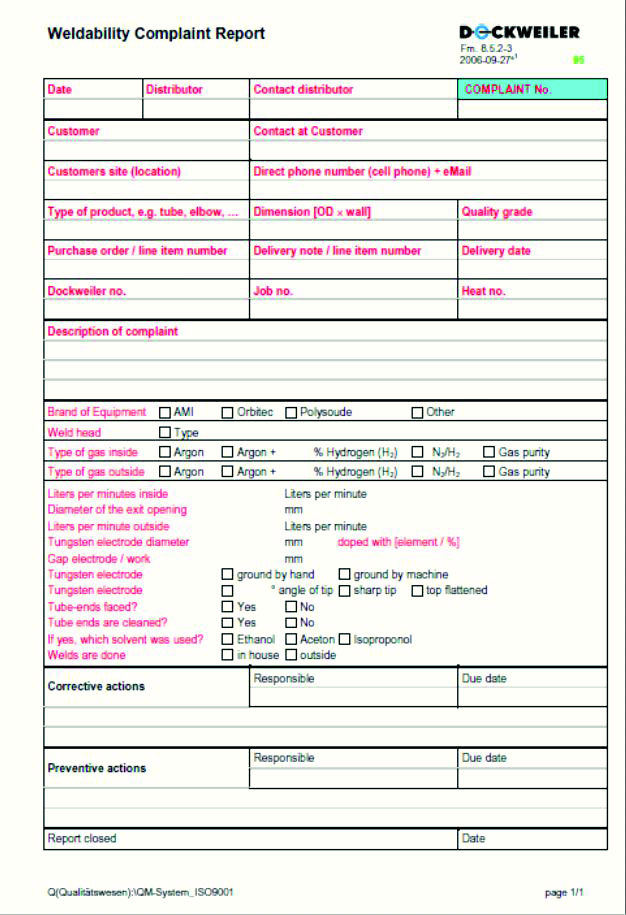

If a customer calls for support he will be asked to provide detailed technical information about the application, the employed equipment and the specific problem and to fill out Dockweiler’s questionnaire “Weldability Complaint Report” (Fig. 6). The experts have to figure out whether the involved staff of the customer is sufficient familiar with the equipment and experienced enough in the field of the particular welding task so that wrong set-up, inadvertent connections, erroneously loaded programs, mistakenly selected materials, inadequate positioned workpieces and other typical beginner’s mistakes can be excluded.

Another important question is whether the problem occurred from the very beginning of the work or if the customer arrived to finish some joints successfully before the campaign failed. Most fundamental programming errors can be easily revealed by the experts – if the program is available. Companies with established welding expertise have often invested considerable amounts of time and money to develop their own reliable procedures and to get the necessary experience, so they consider their know-how as corporate secret which is not allowed to be published to anyone. However, although this point of view is understandable it does not really contribute to a quick and efficient solution of a specific joining problem.

At the first attempt, the Dockweiler experts try their best to deal with the welding problems remotely, but improper operation of electronic components, leakages in the gas supply, temporarily occurring failures and other serious incidents can hardly be analysed without being present on site. In these cases, in agreement with the customer, an on-the-spot support will be organised. Sometimes, rather complex difficulties can only be solved with assistance from the equipment manufacturer. The Dockweiler experts are used to cooperate closely with the service technicians of the respective producer, especially the Polysoude After Sales Service enjoys an excellent reputation concerning targeted advice and immediate action.

Regardless of whether a customer had been bothered by a slight inconsistency of his welding results or faced serious quality problems with his joining technique, in the past the Dockweiler experts always succeeded to find a satisfying solution, and they are firmly decided to do their utmost in the future as well.

Conclusion

Manufacturing of components for high grade stainless steel tube systems in the field of hygienic applications requires a rigorous inspection of all incoming semi-finished products, a distinctive classification concerning the weldability of the used materials and, last but not least, sophisticated production methods. Autogenous orbital TIG welding is considered to be the most appropriate process to ensure a constantly excellent joint quality of the thin-walled tubes. Polysoude, a French company and worldwide leader if it comes to automated TIG welding systems, offers reliable equipment which is customized to be operated in the particular clean room environment.

The unrivalled standard of the produced components is an essential precondition to meet the strict criteria of hygienic pipework, but a sustainable commercialisation of these parts can only be maintained if the customers obtain extensive advice and technical support. Especially the joints made by the customers in their factory or on a construction site deserve close attention. Therefore Dockweiler makes available the related data, e.g. proofed welding parameters, but in case of serious problems the customers are also invited to consult the renowned welding experts of the company. Due to their experience or in close cooperation with the specialists of the equipment manufacturer they arrived in the past to find always an acceptable solution for each problem and they are confident to continue in the same way.

POLYSOUDE S.A.S.

44300 Nantes

France