Smart light

Glass diode laser optics for high-volume applications

For the first time ever, high-grade glass laser optics are now available for price-sensitive high-volume applications such as LIDAR and ID sensors thanks to a new production method. LIMO GmbH, a maker of high-precision micro-optics for laser systems, has become the world’s first manufacturer to successfully process large 300 mm x 300 mm glass wafers and use the wafers to fabricate cost-effective micro-optics.

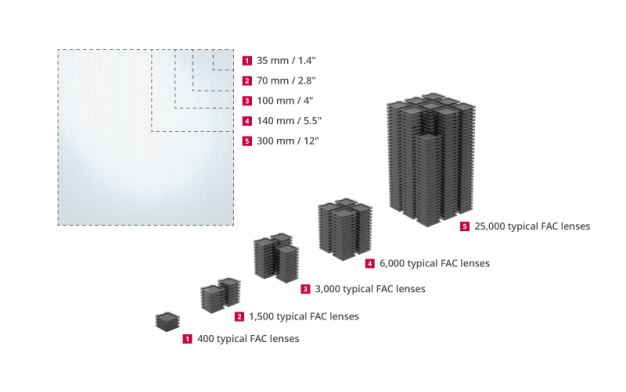

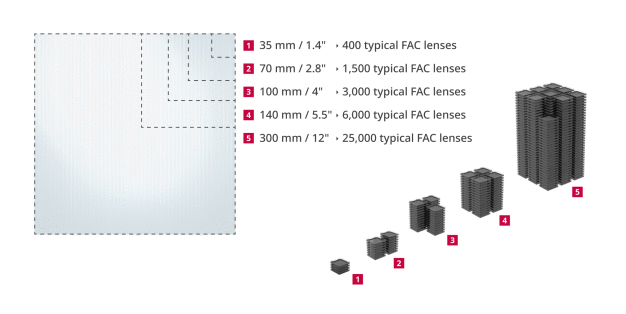

When mass-producing complex glass optics, manufacturers face the challenge of processing large wafer areas with a consistently high level of precision. But in 2018, LIMO achieved a technology breakthrough: The German micro-optics manufacturer managed to produce 140-mm glass wafers for the fabrication of high-precision cylindrical lenses—without sacrificing any quality at all.

After further enhancements to this technique, the company now has the capability of producing 300-mm glass wafers (12 inches x 12 inches). The result: 25,000 FAC lenses with typical dimensions can be made from just one of these wafers, as well as other acylindrical lens arrays featuring consistently high optical quality. The advances in production technology have lowered the unit costs for high-grade diode laser optics made from glass to levels previously only seen for low-cost plastic lenses. For the first time ever, high-quality glass optics can also be used in price-sensitive consumer and high-volume applications. Examples of typical application areas include:

- LIDAR for autonomous driving and autonomous transport (logistics, drones, etc.)

- Communications and data exchange, e.g., for smart computing and smartphones with optical ID sensors

- Defined homogeneous laser illumination for optical measurement

- Security (home automation, data sharing, financial transactions)

- Industry 4.0 applications (machine vision)

The advantages of high-precision glass optics

The biggest advantages of glass optics are their high optical quality, long-term stability, and excellent performance characteristics:

- Glass optics provide flawless and reliable functionality over a temperature range from –40 to at least +105 °C. Glass optics deliver long-term stability while performing consistently over this entire temperature range.

- Glass optics offer consistent optical performance even when used with higher power outputs. Thanks to their zero hot-spot beam shaping, glass optics are also suitable for laser illumination in safety-related applications.

- LIMO’s manufacturing technique makes it possible to freely form surfaces along one axis, which allows the creation of any desired illumination area with an extremely wide angle (field of view of up to 120 degrees). This means that each sensor has a larger field of view—a benefit both in terms of the number of sensors required, e.g. in LIDAR systems, and for all types of consumer electronics in general.

Glass optics for safety-related components

High-quality, economical glass laser optics have the potential to make innovative applications, such as those used in additive manufacturing (3D printing) and for LIDAR systems (laser-based light detection and ranging), suitable for high-volume demand. The LIDAR systems and 3D sensors used for autonomous driving are particularly important components from a safety standpoint, and are also used in harsh ambient atmospheres. Aside from high quality, they also need to deliver reliable operation with long-term stability. The only way to meet these requirements is with laser systems that utilize high-end glass micro-optics.

Improved production method for laser optics made from glass

In 2018, the Dortmund-based LIMO GmbH developed a revolutionary new processing method that is much more productive than the processes that have typically been used in the past for optics and micro-optics. Processing the material at room temperature makes it possible to increase the wafer size for micro-optics without any loss in quality, while also reducing the cycle time per wafer and cutting production costs over the long term. LIMO is the world’s only company to have mastered this type of production process for large quantities.

LIMO GmbH

44319 Dortmund

Germany