Gx Elite vials and RTF vials – top quality and performance for the filling line

Gerresheimer at PDA in San Diego

With its Gx Elite and Gx RTF vials, Gerresheimer is presenting two new type I vials made from borosilicate glass at booth 115 at the PDA Annual Meeting March 11-13) at the Marriott Marquis in San Diego (CA).

Top of their class

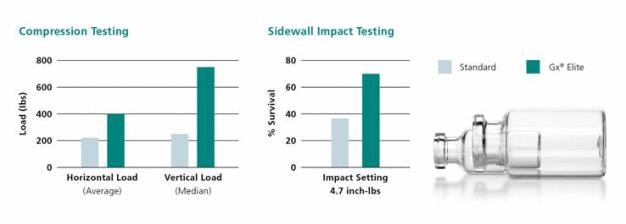

“The Gx Elite vials are the result of a careful product development process spanning several years. This has also impressed our customers,” says Edward Troy, Vice President Sales & Marketing Primary Packaging Glass at Gerresheimer, emphasizing the extent to which avoiding glass-to-glass contact in the production process can affect the quality of the vials. The highly shatter-resistant vials are extremely durable and free of cosmetic defects. They also boast an incredibly robust structure, while their resistance to delamination protects the drug inside. Simple handling and a range of packaging options ensure that Gx Elite vials can be supplied for end-to-end use on various filling lines. This cuts costs while improving quality, as countless past and ongoing tests by notable customers have shown.

Gx RTF injection vials: two manufacturers – one packaging

The Gx RTF injection vials are made from type I borosilicate glass. They meet all current requirements of the applicable ISO standards and pharmacopoeias (USP and Ph. Eur.). By using the Ompi EZ-fill packaging format, the risk of glass-to-glass contact, which could result in breakages, cosmetic defects, and particle contamination, is minimized.

Gerresheimer’s two areas of expertise – the moulding of vials made from tubular glass and the ready-to-fill process for prefillable syringes – are combined with recognized Ompi EZ-fill packaging technology for the new Gx RTF vials. The result is vials that are washed, packed in trays or in nests and tubs, and sterilized before being delivered to pharmaceutical customers. This enables our customers to start filling them straight away without the need for any intermediate process steps.

The new injection vials meet our customers’ increasing desire for comprehensive solutions. By establishing a standardized packaging platform for sterile vials, Gerresheimer is fundamentally simplifying the process for the customer.

Flexibility through various packaging configurations

The new product currently exists in the 2R, 6R, and 10R formats for nests and tubs as well as in formats for 4 to 13.5 ml as trays. Further formats will follow. The new packaging solution allows the vials to be used from the development phase of new medications to small or large-scale production.

Injection vials set the benchmark for primary packaging for parenteral drugs. Gerresheimer’s come in all sizes and comply with the relevant international standards and pharmacopeias. The company’s range includes solutions for bioengineered drugs and other specialist pharmaceuticals.

Gerresheimer AG

40468 Düsseldorf

Germany