Highly Accurate Feeding Solution for Growing Demands of Continuous Processing

Coperion K-Tron Displays Innovative Feeder Design for the Pharmaceutical Industry

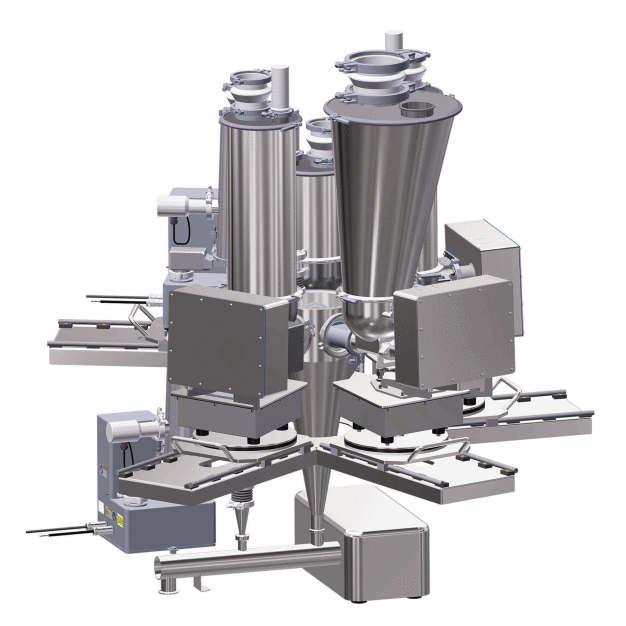

At this year's Interphex (April 2 to 4, 2019, booth 2558, New York/USA) as well as at Powtech (April 9 to 11, 2019, hall 4, booth 4-290, Nuremberg/ Germany) Coperion K-Tron will display the next generation of its highly accurate, gravimetric K3-PH feeders for the pharmaceutical industry. These modular feeders have been specially designed to meet the growing demands of continuous processing. Thanks to the use of a smaller D4 platform scale incorporating the patented and highly accurate Smart Force Transducer (SFT) weighing technology, they require significantly less floor space compared to previous models. Depending on the process and requirements, several feeders can be grouped into a cluster, for example for continuous processes such as direct compression (CDC), extrusion, wet and dry granulation, and continuous coating as well as traditional batch processes.

Easy handling and better product quality

The modular design of this innovative feeder line simplifies cleaning and reduces changeover times. The "Quick Change" design, whereby the feeder bowl can be quickly decoupled from the feeder drive, also enables simple and fast product changes. By simply releasing two clamps, the used feeding unit can be removed and replaced with a clean one.

The three available Coperion K-Tron feeder types QT20, QT35 and QS60 (twin and single screw) can be used with the same scale and drive units. They are interchangeable, depending on the product to be fed, the required feed rates and the necessary scale resolution. For an optimal Wet-In-Place (WIP) result, every unit has an integral two degree pitch facilitating maximum drainage during the cleaning process. In addition, the feeder bowls and hoppers feature a new improved seal design for optimal product containment. The complete line of equipment is engineered to meet the rigid requirements of the pharmaceutical industry, including strict adherence to cGMP guidelines and standards as well as the use of FDA approved materials of construction. Initial industry reactions to the design include very positive comments on the use of a single gearbox for the complete speed ranges of all feeder models.

High-accuracy weighing with patented SFT technology

The new D4 platform scale features the same state-of-the-art sanitary design of the established Coperion K-Tron D5 scale. Smooth, crevice free surfaces prevent deposit of dust and product residue and enable easy cleaning. The redesign of the scale from a round design to a trapezoid design features a much smaller footprint and facilitates an optimized multi-feeder arrangement. This is especially useful in areas with limited space, where multiple ingredients must be fed into one process inlet. At the heart of the new D4 scale, Coperion K-Tron’s patented SFT single wire weighing technology provides a highly accurate weight signal with a resolution of 1:4,000,000 in 80 ms. The electronics include linearization, temperature compensation and a digital low-pass filter to reduce the effect of plant vibration. The 100% digital design eliminates the need for calibration.

Coperion GmbH

70469 Stuttgart

Germany