- Building technology

Safe remote microbial air sampling with MAS-100 ISO MH

Abstract

Active microbial air sampling is performed in isolators and RABS to detect potential product contamination by airborne microorganisms. Two MAS-100 Iso MH impaction-based microbial air samplers were successfully tested for these applications: (1) sampling air 50 m from the instrument base unit which in practice permits to place the base unit in an uncontrolled technical area far from the space-restricted isolator (2) inclusion of a filter into the air duct which protects personnel from exposure to toxic API’s (3) air-flow calibration of the air sampler without the need to access the isolator (4) Assuring identical microbial air sampling efficiency for each of the up to 4 sampling heads of the MAS-100 Iso MH and (5) the possibility to replace the base unit of an MAS-100 Iso MH while maintaining the integrity of the isolator.

The rugged design of the standard MAS-100 Iso MH enables specific installation options which make this instrument the safe choice for microbial air sampling in isolators and RABS.

Clean air supply is a defining criterion of an aseptic filling system within an isolator or RABS. Microbial air monitoring of these environments is performed with settling plates and active air samplers. Sampling locations are chosen based on a risk analysis within a QRM framework. In aseptic filling lines most frequently three positions are monitored: Entry and exit point of material as well as the filling position where product is exposed to the environment. The integrity of the containment must be guaranteed throughout the process.

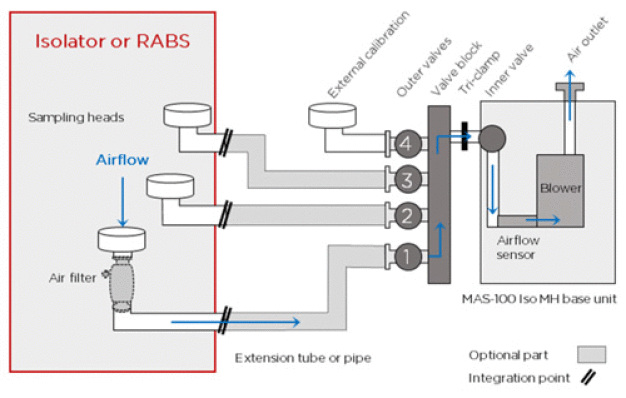

The MAS-100 Iso MH impaction-based air sampler from MBV has specifically been designed for air monitoring in isolators and RABS. The instrument consists of up to 4 pharmaceuticalgrade stainless steel sampling heads inside the containment which are connected by pipes or tubes to a base unit outside the isolator. The base unit includes a temperature and pressure-compensated mass flow sensor, communication interfaces, valves and the air blower which aspirates air with a sensor-controlled rate of 100 SLPM through the sampling heads. In one possible set-up, 3 sampling heads are placed within the containment and the fourth sampling point remains outside the isolator.

In the following tests we will investigate if the integrated mass flow sensor of the MAS-100 Iso MH maintains a constant sampling rate of 100 SLPM by automatically adjusting the blower speed to compensate for different air resistances within the air channel. If so, this would permit calibration of one channel of the instrument (e.g. the one outside of the contained compartment) and extrapolation of the result to the remaining sampling heads. The resistance-independent calibration would also allow for different channel lengths and geometries and the integration of a protective air filter in the air channel.

Material and methods

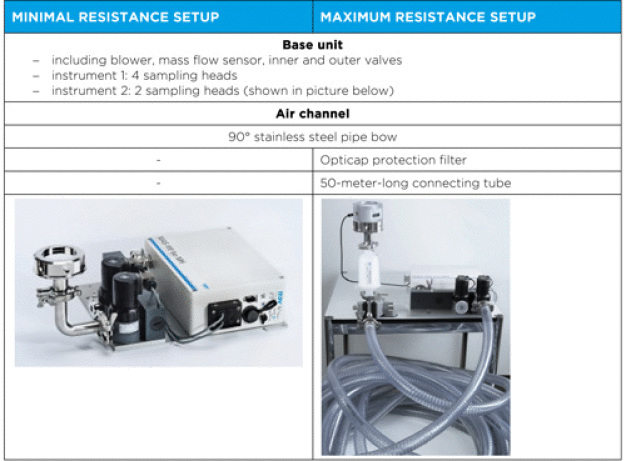

We tested whether differences in air resistance between the sampling head and the base unit of a MAS-100 MH instrument influence the amount of sampled air. The channel configuration with minimal air resistance consisted of a 90° stainless steel pipe bow with 3/4’’ inner diameter of a total channel length of approx. 0.2 m. The maximum resistance set-up consisted of a 50 m spiral coiled tube (transparent, 32x4.2 mm, #01201326, Helispring, Gummi-Fischer GmbH), the same 90° bow and an Opticap® XL4 Capsule Filter (0.2 μm pore size, Merck Millipore) which is frequently used to prevent release of toxic substances from inside the isolator. The total channel length was about 50.4 m (Table 1). The experiments were performed with two different MAS-100 Iso MH with either 4 (SNR 450019) or 2 sampling heads (SNR 450146) with standard 300x0.6 perforated lids with a D50 cut-off value of 1.1 μm. All channels of both instruments were initially adjusted to a target air flow of 100 SLPM and calibrated with a DA-100 NT digital anemometer.

After adjustment we performed air flow measurements with the minimal (no tube, no filter) and maximal resistance (50 m tube, protective filter) and compared them to the target air flow. The experiments were repeated to provide an indication of the systems robustness. The specified precision at 100 SLPM of the DA-100 NT is ±1% and for the MAS-100 Iso MH it is ±2.5% To account for sudden environmental changes in combination with instrument and test equipment variation the ex-factory limits for air flow deviation are set to ±5%. However, this experiment was performed under controlled conditions and we targeted to stay within a band of 100 SLPM ±2.5%.

Results

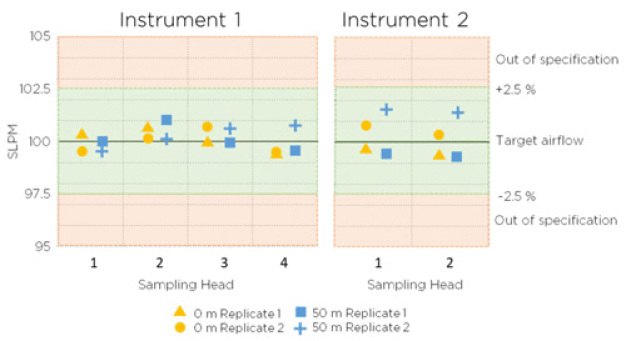

Inserting a long connecting tube and a protective air filter between the sampling head and the base unit increases resistance to the sampling airflow.We tested the relationship between the increased air flow resistance and the resulting air flow rate at the sampling point. Fig. 1 shows the results of the 6 tested sampling channels and the two repetitions per channel (4 channels of MAS-100 Iso MH instrument 1 and 2 channels of instrument 2).

Every single airflow difference between minimal and maximum resistance of an individual channel was below ±1.5 % of the 100 SLPM target flow and therefore well within the specified range of the MAS-100 Iso MH of 100 SLPM ±2.5 % (green shading in Fig. 1). The mean difference of instrument 1 was -0.25 % and for instrument 2 it was -0.35 %. In all cases the mass flow sensor controlled the blower speed such that no significant differences between the calibration with minimal and maximum airflow resistance were detected. Consequently, all 12 data points across 6 channels and 2 instruments were well within the specification of 100 SLPM ±2.5 %. The increased air channel resistance was compensated by an increased power output of the blower, which increased from 48 % (no tube) to 67 % (with tube and filter) of the maximum output. So despite the significant additional drag in the air duct, the blower still had a residual additional capacity of more than 30%.

Discussion

We tested the stability of the calibration of two MAS-100 Iso MH impaction-based microbial air samplers under different air resistance conditions. We found no significant differences of airflow between minimal and maximum resistance conditions (Fig. 1). This is because the combination of a mass flow sensor that controls a strong blower motor compensated the increased airflow resistance. This positive outcome offers several practical implications in real containment set-ups (Fig. 2):

1. Remote microbial air sampling

The long tubing or piping between the sampling locations and the base unit enables a large physical separation of the base unit from the containment. Space in controlled environments is always at a premium. The tubing length of 50 m which we tested in this experiment and which is much longer than the 10 m specified for the MAS-100 Iso MH will permit to place the base unit of the MAS-100 Iso MH in the uncontrolled technical zone, for instance into the floor above the cleanrooms. The base unit will then be accessible without gowning and tool sterilization.

2. Protective air filter

Many modern pharmaceutical products such as antibody drug conjugates (ADC) are highly toxic. Protecting personnel from exposure to these substances is therefore a prime concern for workplace safety. We have inserted a protective air filter between the sampling head and the base unit of the MAS-100 Iso NT. The additional resistance to the airflow introduced by adding the filter had to be compensated by the blower. In our experiments this was achieved with 30% residual power output reserve of the blower.

3. Air-flow calibration during running filling processes

The MAS-100 Iso MH permits microbial air sampling on up to 4 sampling heads from one base unit. The airflow from these 4 channels is measured by a single mass flow sensor which controls the aspiration speed of the blower. If 3 sampling locations are inside an isolator, then the fourth sampling head could be used to calibrate the flow sensor. Our tests suggest that the calibration result of this head can be used as a reference for the air flow of all other channels. In such a set-up an ‘as found’ calibration can then be performed on each channel once the isolator is opened for maintenance and, if necessary, the air flow can be adjusted.

4. Identical sampling efficiency for each sampling point

During factory calibration, IQ/OQ and the regular re-calibrations, each channel of the MAS-100 Iso MH is separately adjusted and calibrated with a DA-100 NT digital anemometer. The calibration data is stored in the base unit and a calibration certificate is automatically generated for each channel. This is to ensure identical microbial air sampling efficiency for each sample. In our experiments these calibrations remained valid even if the air channel resistance was changed. For other installation set-ups this finding may need to be verified.

5. Service exchange of air sampler with containment still intact

The MAS-100 Iso MH has been specified and manufactured for robustness and longevity. However, technical failure can never be totally excluded. Should a MAS-100 Iso MH experience any problems during operation, the base unit can be exchanged without compromising the integrity of the containment. The outer valve of the dual-valve protection system keeps the air channel closed even if the base unit is removed and replaced by a calibrated replacement unit (Fig. 2). The ‘as found’ calibration results for each channel will have to be verified and if necessary adjusted and calibrated once the sample heads are accessible during routine maintenance operation.

Conclusion

With this application note we demonstrate on two units and a combined 6 sampling channels of the MAS-100 Iso MH microbial air sampler the remote active microbial air monitoring in isolators and RABS. Each of the up to 4 sampling points was placed 50 m from the instruments base unit. Additionally, a protective air filter was introduced into the air channel. Despite this additional resistance to the air flow, no re-calibration/adjustment of the air sampler was required as the integrated flow sensor maintained the air sampling rate by adjusting the air aspiration speed of the blower. Air resistance in a real isolator/RABS setting depends on a number of factors such as tubing/piping bow radii or pressure differences between controlled zones. Although we expect similar results to our findings, it is advisable to perform a feasibility test for installations outside the instrument specifications of the MAS-100 Iso MH. It may also be necessary to adjust other installation parameters. For further information contact MBV.

The stability of the flow-sensor calibration in combination with standard safety features of this instrument offers a number of practical advantages. These range from easier mechanical integration to increased service friendliness and provide the user with the ease of mind to comply with the requirements for save microbial air monitoring.

MBV AG

Microbiology and Bioanalytic

Industriestrasse 9

8712 Stäfa

Switzerland

Phone: +41 44 9283080

email: welcome@mbv.ch

Internet: http://www.mbv.ch