Daniel Krause B.sc., Sales Engineer Industrial Air Technology bei ebm-papst Mulfingen

Extracting emissions – high performance for clean air

Conversion to ErP-compliant EC fans

Every employee has a right to breathe clean air. That is also the case in the metalworking industry, where the cooling lubricants used for cutting and non-cutting machining are a source of aerosols, oil mist and vapors that pollute the air in production facilities (see Fig. 1), which is detrimental to the environment and can endanger the health of employees. As a result, statutory limits apply. To ensure that these limits are not exceeded, machine tools and machining centers are usually equipped with centralized or decentralized air purification units. As ErP-compliant drives for their fans, modern EC motors are well suited for a number of reasons.

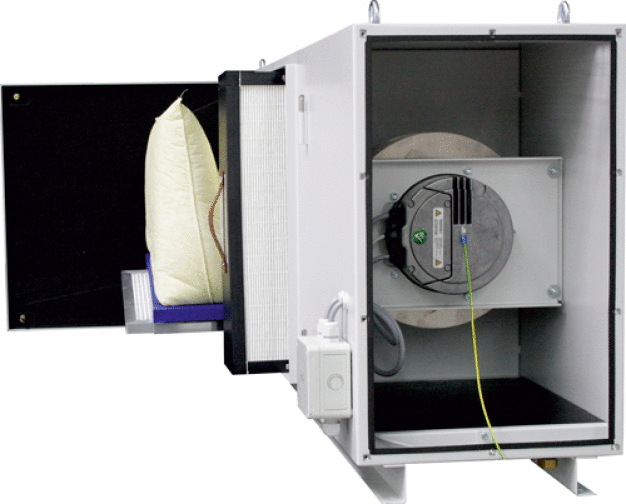

Air purification units generally make use of a multistage filtering and separation process. Fans ensure that the contaminated air extracted from metalworking machines passes through the various filter systems (see Fig. 2), safely extracting emissions such as oil and emulsion mist and suspended particulate matter. This process calls for fans that generate relatively high pressure from a low air flow. The high pressure is needed to overcome the resistance from the filters. The fans should also be as easy to control as possible. The extraction flow can then be adjusted to the actual need, enabling energy-saving partial-load operation that also extends the service life of the filters. At the same time, the extraction performance can be kept constant in spite of increasingly clogged filters by appropriately adjusting the motor speed, and performance reserves can be made available for future system expansion as the speed and air performance can be adjusted as needed later.

AC motors reach their limits

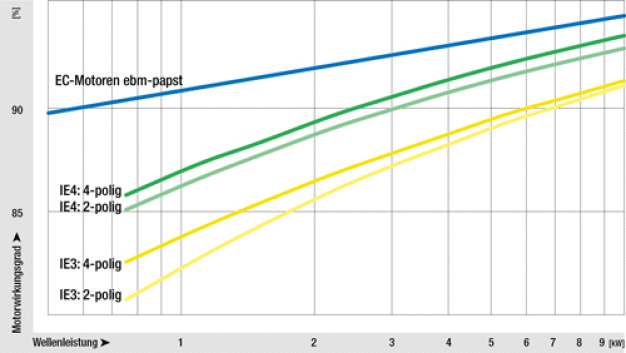

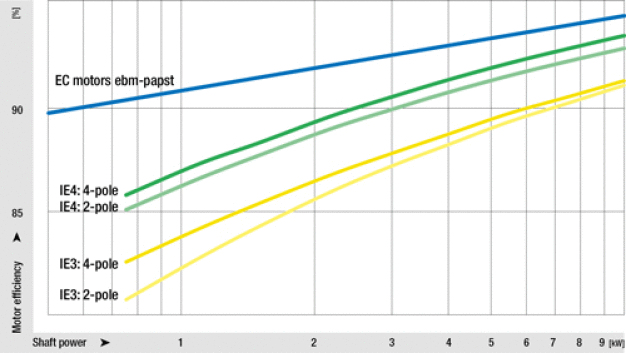

Until recently, AC motors with variable frequency drives had been considered suitable for operating fans. That has changed, since such motors often fail to comply with the current requirements of the European Union’s Ecodesign (ErP) Directive. Now modern EC fans often present an ErP-compliant alternative in many cases (see Fig. 3). An example is the innovative GreenTech EC technology developed by ebm-papst, which can play out all its strengths in air purifiers. EC motors are basically permanent-magnet synchronous motors in which a magnetic rotor synchronously follows an electronically generated rotating field. Their control electronics allow operation at any speed, even above the 3,000 rpm limit imposed on asynchronous motors by the line frequency.

High efficiency, smooth operation and connectivity

EC fans work at much higher efficiency levels than asynchronous motors. Their optimized commutation allows partial-load operation down to 1:10 without a loss of efficiency, while their air flow can be adjusted as needed with a 0-10 V linear or PWM input. A PID controller is integrated in their motor electronics. Multiple fans can be conveniently networked via MODBUS and then controlled with a centrally connected air-monitoring system, and of course diagnostic and warning functions can also be used via the bus at the same time.

The high efficiency of the EC motors not only saves energy and lowers operating costs, but also generates less waste heat so that factory buildings are not additionally heated by the air purifiers during the summer. Commutation and the motor design also ensure very smooth operation. The high cycle frequencies are acoustically imperceptible, reducing noise emissions and making these “stealth fans” ideal for applications in which noise protection regulations must be observed; in some cases, manufacturers can then use less insulation.

But it is also possible to go a step further. Moving air is always accompanied by a certain amount of noise. If the EC fans are now combined with air-inlet guards (see Fig. 4) on the intake side, a drastic reduction in noise emission results and turbulence and annoying low-frequency sounds are minimized. This reduces the frictions that can otherwise arise when people and machines share the same space.

Easy installation and commissioning

The fans from ebm-papst with backward-curved, aerodynamically optimized aluminum impellers for use in air purifiers are available in sizes 250 and 310 (see Fig. 5). They cover a range of drive powers between 250 watts and 12 kW. Flexible options for installation include short delivery times and mounting with vertical or horizontal motor shaft orientation. With their compact dimensions, they are also suitable for retrofits, as when energy-saving replacements are called for or increased air performance is needed in a limited space. Such retrofits usually require minimal adaptations, if any.

Since the electronics and motors in the EC fans are combined in a single unit, installation is simplified and requires less space. Since the motor and the electronics in the motor system are already perfectly matched, there is no need for additional electronic filters and shielded cables. Nor is an external motor protection switch required. Costly adaptations during commissioning in the air purification units can be dispensed with, as can grounding and shielding. All these characteristics make the energy-efficient and ErP-compliant EC fans a worthwhile alternative for centralized or decentralized air purification units.

ebm‑papst Mulfingen GmbH & Co. KGaA & Co. KG

74673 Mulfingen

Germany