Gentle and Reliable Drying – Innovation for Pharma Products

Drying Technology

„Heat pump based condensation drying“ is the solution to many a drying challenge. It combines seemingly conflicting features such as low temperatures and short drying times. The purpose devised Airgenex® condensation drying system and its variants AIRGENEX®med and AIRGENEX®food are capable of drying, in a gentle and stress-free way at temperatures between 20 °C and 90 °C, items made from metal, glass or plastic, or organic products such as food. Quality drying results at very short times are obtained through the use of extremely dry air routed as required for the specific application. The integrated heat pump technology ensures highest efficiency of the drying process. Drying always takes place in a closed system, which makes it absolutely independent of the climate. Clean room environments are not affected. This ensures best quality and process reliability. Airgenex® condensation drying is a flexible system which may be integrated in any process. Air dehumidification by means of a heat pump may be implemented in any batch or continuous operation. Airgenex® drying systems meet GMP and GAMP requirements.

Drying Tests to be on the Safe Side

Our in-house pilot plant station is used to test customer products for response to drying. This is both part of the services offered and a reasonable method for determining the parameters for successful drying such as temperature, humidity, drying time, air speed and airflow. The documented results, our long experience plus the customer’s know-how form the basis for further system design which will also draw on approaches for solutions in hundreds of various projects.

Drying and Cooling

With minor modification, our AIRGENEX® condensation drying system may also be used for cooling if desired or required by your process.

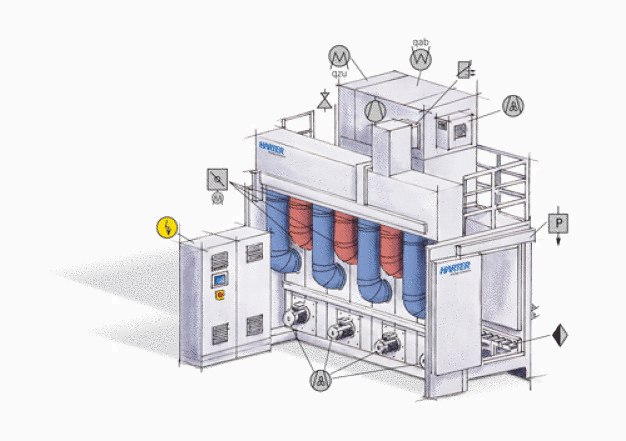

Condensation Drying - How it Works

The so-called AIRGENEX®med drying method uses an alternative physical approach. Extremely dry and, thus, unsaturated air is passed over the items to be dried to absorb any humidity. In a downstream dehumidification module, the air is stripped of the humidity it carries. The humidity is condensed and the condensate drained off. Subsequently, the cooled air is reheated and recirculated. The loop is closed. This makes the drying cycle almost emission free. The AIRGENEX®med module controlling dehumidification is integrated in the drying station. It does not matter if batch or continuous drying is used. The drying chamber includes a custom-designed air recirculation system. Because it is the perfect combination of dehumidification, air routeing, air speed and airflow rate that ensures successful condensation drying for your product.

Batch Drying and Cooling - Application Example #1

A drying-cooling tunnel is loaded with batches of 12 support assemblies including 7 trays each. These hold, for example, a total of 15,000 infusion bottles with a capacity of 500 ml. Sterilisation takes 120 minutes. After sterilisation, the bottle temperature is about 55 °C. Upon customer request, the process of drying and subsequent cooling was adapted to the given cycle time. Thus, the bottles also dwell in the drying tunnel for 120 minutes. Drying is completed after 20 minutes. The remaining 100 minutes are used for cooling of the bottles to ensure smooth transition for further processing. The energy released in the cooling process is, in this application, removed through the existing cooling water system. All infusion bottles are now dried and cooled in a uniform and gentle way. Drying and cooling are fully reproducible. The tunnel has an in-built air recirculation system to produce a high and controlled airflow. The tunnel has an AIRGENEX®med 40.000 dehumidification module attached to provide the necessary environmental conditions for the various process stages inside the drying-cooling tunnel. Upon customer request, the module was placed atop the tunnel.

Application Example #2

Racks supporting cassettes holding vials with a capacity of 5 to 100 ml are loaded in a drying-cooling tunnel after sterilisation. The vials are dried at 55 °C for 45 minutes and subsequently cooled to 35 °C for 30 minutes. The drying-cooling tunnel is designed to accommodate three racks. A total of three special fans inside the tunnel provide optimum air routeing with each fan providing its own recirculating system to pass the dry air required for drying through the applicable rack / cassettes. The total airflow rate produced is about 30,000 m³/h. This way, the drying process will run smoothly with partial loads, too. The system has an input power of only 33.4 kW. Existing leakage test systems can produce valid results now that the vials are truly dry and no longer indicate suspected leakage. False rejects, which were really vials with residual external humidity, are a thing of the past. The drying-cooling also eases downstream processes such as stamping, labelling or printing. Also, packaging cool vials is much easier.

Continuous Drying – Application Example #3

For some projects, the process is different, which means infusion bags are dried after separation. Robots separate the infusion bags and place them on conveyor belts. A non-compressed air blowing type drying tunnel was integrated in the line to the test / packaging stations. In such cases, trays are not dried together with the bags.

Harter Oberflächen- und Umwelttechnik GmbH

88167 Stiefenhofen

Germany