Environmental report details how new packaging concept for DuPont™ Tyvek® Classic Xpert can help reduce greenhouse gas emissions

The results of a report (1), commissioned by DuPont, reveal that the new DuPont™ Tyvek® Classic Xpert Eco-Pack can have a significantly reduced impact on the environment when compared to its standard packaging format. Accordingly, over the entire lifecycle of the packaging (2), there is the potential to reduce the emission of greenhouse gases by three tonnes CO2 equivalent, achieve a saving of 77,700 MJ of primary energy, and decrease solid waste by 820 kg. Besides the environmental benefits, the new Eco-Pack can help users of the garments avoid costs relating to the handling and disposal of packaging at the end of their useful life.

In its standard packaging form, each Tyvek® Classic Xpert garment is individually packed in a polybag together with a user manual (referred to as Instructions for Use, or IFU). 25 coveralls are then grouped within a value pack, and each box contains 4 value packs, making 100 garments per box. “As part of DuPont’s new Tyvek® Classic Xpert Eco-Pack packaging concept, the 25 garments within the value pack are no longer individually packed, and there is just one user manual per value pack. Hence the packaging saving equates to 100 percent in terms of the polybags, and 96 percent in IFUs,” explains Deborah Sondag, marketing specialist EMEA, DuPont Protection Technologies.

The report, entitled The Environmental Benefits of Packaging Reduction, and carried out by BIO by Deloitte, quantifies and compares the environmental impact of both packaging concepts using a standardized Life Cycle Assessment approach. As a first step, a life cycle inventory is created for the individual stages involved in the production of the polybags and IFUs, their delivery to DuPont (up-stream processes), their onward transportation to customers and ultimate disposal (down-stream processes). Thereafter follows an evaluation of their environmental impact in terms of global warming potential, air acidification potential, net water consumption, primary energy demand and waste generation.

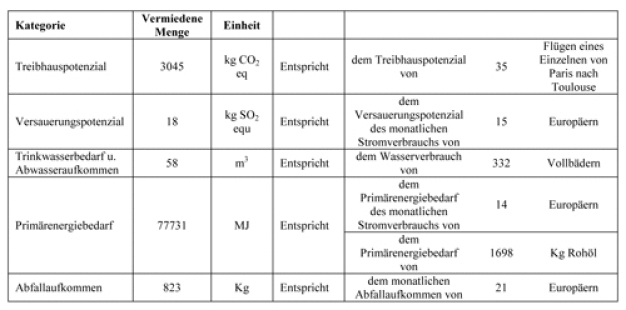

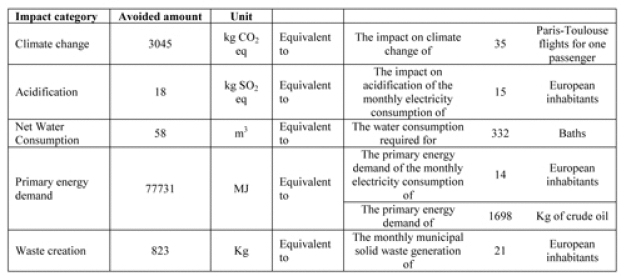

Three separate scenarios were considered for the assessment, differing in terms of number of garments shipped, shipping distance and end-of-life scenario (landfill, incineration or recycling, depending on the waste management practice of the destination country). Based on a shipment quantity of 35,000 coveralls transported by truck to France (scenario B), the following benefits of Tyvek® Classic Xpert Eco-Pack over standard packaging were predicted: see figure 1.

Deborah Sondag continues: “In a context where environmental impacts are more and more important regarding the communication strategy of a firm, DuPont wants to provide its customers with clear environmental claims on these improvement actions, allowing them to easily integrate the related environmental benefits within their own environmental management program.”

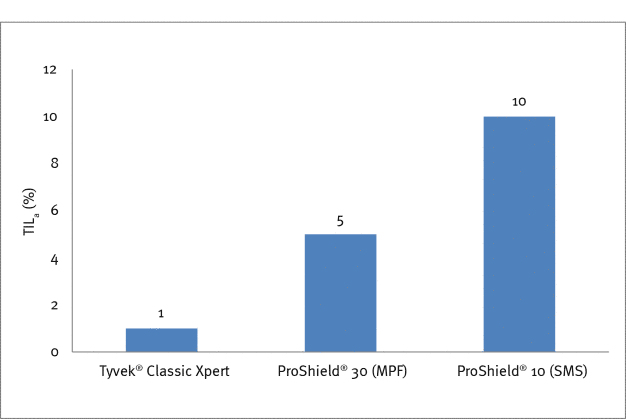

Tyvek® Classic Xpert is the market-leading Type 5 (particulate) and Type 6 (liquid) disposable protective garment. Indeed, whilst there are many alternative garments also certified as providing similar levels of protection, a detailed look at their results delivers greater insight as to their actual barrier performance of the garment in question. For instance, the average total inward leakage of particles into a Tyvek® Classic Xpert garment, measured as part of the testing requirements for Type 5 protective clothing, is just 1 %. This compares favourably to 5% for a typical microporous (MPF) film garment or 10% for a typical SMS garment (see figure 2). Factors determining the particle barrier provided by the garment include the fabric used, seam construction and overall design.

Also in terms of providing a durable barrier to liquid, it is worthwhile looking at Tyvek® performance in closer detail: In tests used to determine the resistance of fabrics to liquid penetration and permeation, Tyvek® is demonstrated to provide a high barrier both before and after abrasion, while the levels of competitive materials are either inferior from the outset or fall away spectacularly after abrasion.

(1) Bio IS were requested by DuPont de Nemours to produce a Report presenting the conclusions on the “Environmental benefits of packaging reduction”. The Report was prepared for the DuPont de Nemours’s confidential use, on the basis of contractual terms of reference agreed upon with the DuPont de Nemours to meet specific requirements and which may not be appropriate to meet the objectives of any other party who is a third party in relation to the Engagement entrusted to Bio IS. Its work should not be taken to supplant any additional inquiries or procedures that should be undertaken by a third party recipient of this attestation and it makes no representations regarding the sufficiency of the procedures it performed for the purpose of third parties. Bio IS release any responsibility of the use which could be made by the report by a third party. It didn’t audit or otherwise test or verify the information given to it in the course of the services provided.

To conduct this report, Deloitte used the Lifecycle Assessment Method. Life Cycle-based approaches are now mandatory for all existing product standards (PAS 2050, GHG Protocol scope 3, European Product Environmental Footprint (PEF)) LCA carried out according to 14040 and 14044 ISO standards is:

- multi-steps, assessing potential impacts of a product all along its whole life cycle

- multi-criteria, taking into account a wide range of environmental issues (climate change, air acidification, water eutrophication, consumption of non-renewable natural resources, etc.)

(2) Based on a shipped quantity of 35,000 coveralls by truck to France.