A wide range of solutions for the flexible and secure packaging of medical products

16 - 19 November: MULTIVAC at COMPAMED 2015 in Düsseldorf

At COMPAMED, which takes place from 16 to 19 November in Düsseldorf, MULTIVAC will be showing innovative packaging, labelling and marking solutions for sterile items and other medical products, among them a compact thermoforming packaging machine for packing products in small batches. All MULTIVAC's packaging solutions are individually designed for the product that is to be packed. The result is a comprehensive packaging system, which guarantees not only maximum pack quality but also a flexible, secure and reproducible packaging procedure.

With the R 081 thermoforming packaging machine, MULTIVAC will be presenting an entry-level model that is designed for packing products in small batches. The R 081 is also suitable for cleanroom applications and can be used for producing both vacuum packs and modified atmosphere packs with reduced residual oxygen content. The machine can run both flexible and rigid films as well as Tyvek® and paper-based packaging materials. It is equipped with electrical lifting units, which contribute among other things to a consistently high level of sealing quality.

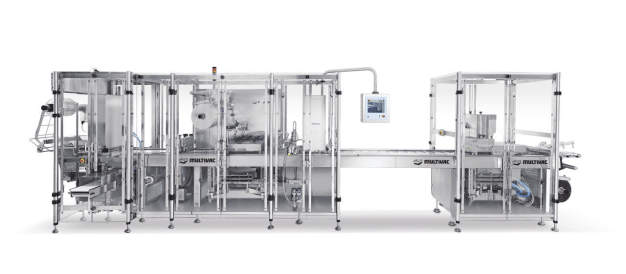

In addition to this, MULTIVAC will also be showing a thermoforming packaging machine in the MULTIVAC Clean DesignTM, which can run a wide range of packaging materials and is designed to pack sterile medical products to GMP standards. MULTIVAC's proven drawer system provides for frequent, reproducible and quick format change. This machine also makes changing the cutting tool of the complete cutter significantly easier. This means that the machine is very flexible when it comes to packing different products in different batch sizes. In the interests of reliable line clearance, the area for product processing is strictly separated from the area of the machine equipment. Transparent enclosures with large doors protect against environmental influences and, thanks to perfect overview of the process, they increase the security of the packaging procedure against any products being lost.

With the T 260 there will be a traysealer model on view at COMPAMED, which enables medical products to be packed in accordance with GMP guidelines, particularly with regard to packaging quality, process reliability and cleanroom compatibility. The sealing die of the T 260 ensures that there is controlled sealing pressure with high sealing forces and precise temperature distribution, and this gives a consistently high level of packaging quality.

As regards the packing of products in film pouches, MULTIVAC will be presenting the C 200 TC and C 300 TC chamber machines. Their permanently heated sealing bars offer a high degree of process reliability and reproducibility. Thanks to the IPC control of these chamber machines, which can be validated and calibrated, all the processes can be monitored and controlled.

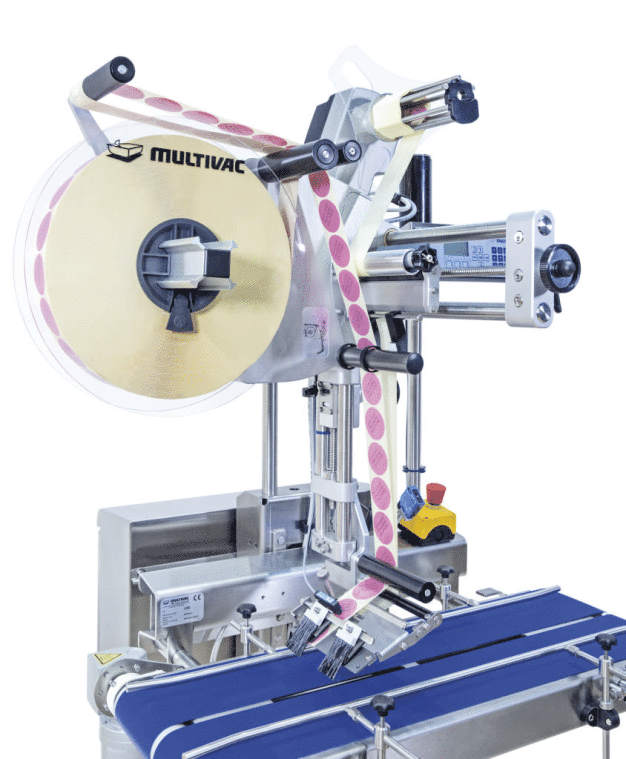

As regards the area of labelling, the BASELINE L 300 conveyor belt labeller will be exhibited, a cost-effective solution for simple top and bottom labelling tasks as well as applying labels over the edge of packs.

MULTIVAC Sepp Haggenmüller GmbH & Co. KG

87787 Wolfertschwenden

Germany