RAUMEDIC shows micro molding parts, thermoplastic PTFE Moldflon and its Silicone expertise.

MEDTEC Ireland

For the second time, RAUMEDIC will be presenting the latest developments from the world of polymers at MEDTEC Ireland in Galway, the industry meet-up for the medical technology industry.

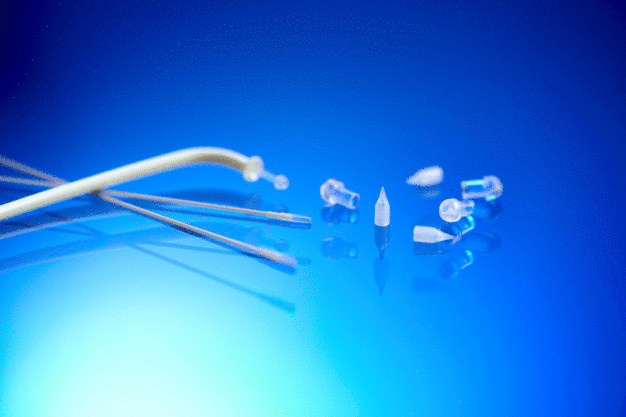

At this year's event, the precision injection molding capabilities of RAUMEDIC will play an important role. Micro molded parts, as tiny that you will need a magnifying glass to see them properly, are in the focus of attention. RAUMEDIC processes also high temperature materials such as PEEK, PSU and PPSU in clean room conditions, for many medical technology and pharmaceutical application. This is highly advantageous, as the company is also well known for its expertise in micro extrusion, and the micro molding technology just completes the portfolio of the single source supplier.

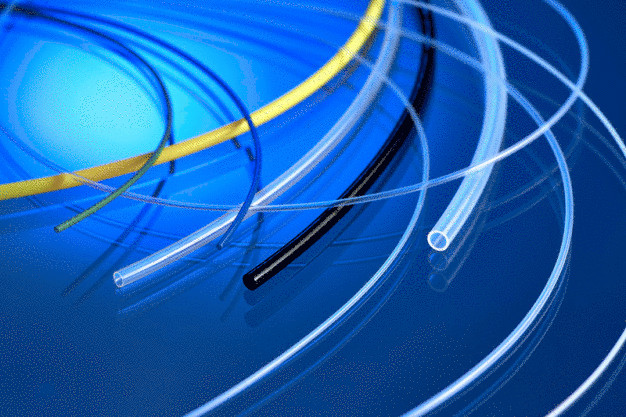

What's more, the company will also be showcasing its tubing, extruded from PTFE Moldflon. This is a special type of thermoplastic material provided by ElringKlinger that, in contrast to regular PTFE (polytetrafluoroethylene), can be processed from the melt – a major advantage in terms of economy and processability for PTFE. Further testing has also been performed to realize the benefits of PTFE Moldflon for secondary thermo forming operations such as tipping and flaring. PTFE Moldflon is a biocompatible thermoplastic with very similar physical properties to traditional PTFE such as melting point, continuous service temperature, coefficient of friction, tensile strength and dielectric constant. The main benefit from PTFE Moldflon is that it can be processed from the Melt. This is highly advantageous for long continuous PTFE tubing production runs and for PTFE with co-extruded radiopaque stripes. Perhaps the biggest development is the extrusion of PTFE for lubricous inner catheter liners and for insulating fine wires for electrical stimulation applications.

Visitors will have the opportunity to drop by the thermoplastic and silicone processor and form their own opinion on how these two materials are processed as part of a unique injection molding process. This multifunctional one-shot technology provides the system components for catheter sets in one single working step.

Raumedic AG

95233 Helmbrechts

Germany