Reduced ozone input lowers operating costs

H+E presents optimised AOP procedure

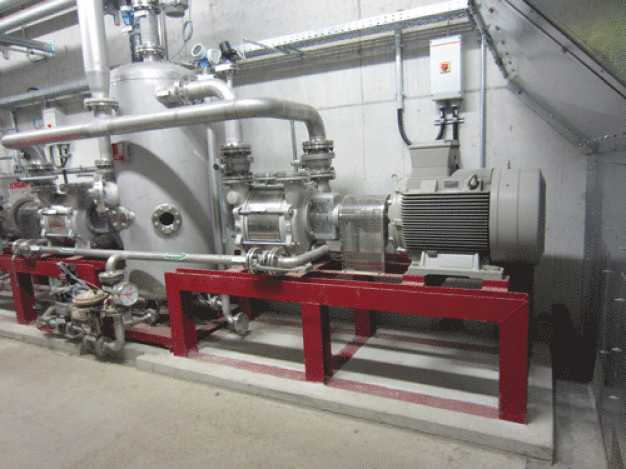

Hager + Elsässer (H+E), one of the leading solution suppliers worldwide for holistic water management systems, draws on over 20 years of experience with the Advanced Oxidation Process (AOP). Here, the cleaning of difficult waste water takes place by oxidation with strong oxidisers like ozone or peroxide and an optional biological cleaning stage. At the Achema 2015, H+E will be presenting an improved AOP procedure that lowers the operating costs by reducing the energy input and the specific share of ozone used, and is at the same time more environmentally friendly than conventional systems. This is achieved by a multistage low-pressure process of the ozone input and optimised process operation, in combination with a biological stage.

Legal specifications on pollution levels in waste water are increasingly putting the productive industry, but also municipalities under pressure. Whereas the limiting values for materials contained in waste water have been reduced continuously, industrial companies want to produce with less and less water, which in turn results in higher concentrations of persistent substances. These developments particularly affect the paper and cellulose industry as well as petrochemicals. These sectors release highly persistent substances, which cannot be degraded biologically without further measures. With the Advanced Oxidation Process (AOP), persistent substances, the so-called hard COD (chemical oxygen demand) are oxidised by the use of ozone. As distinct from other providers that rely on an AOP process with full chemical oxidation or alternatively on an adsorptive or precipitative method with very high residual material quantities in each case, H+E uses a combination of chemical and biological processes.

Here, the contents are cracked in a first stage with reduced energy and oxidiser input, just enough to make them accessible to biological degradation. The persistent, hard-to-remove substances include molecular rings or double bonds. The structures must therefore be opened and converted into short chain molecules. Here, H+E uses multistage low pressure feed systems that are characterised by a low energy requirements and are simultaneously regulated in such a way as to minimise the ozone requirements. The efficient input of chemicals is supported by a system creating the largest possible surface area renewal in the reaction zone, combined with low energy input. As a result, and with the regulated ozone input and corresponding short residence times, the limitation of the reaction to the breaking open of the double bonds is achieved.

The fragments resulting from this process can then be economically degraded biologically in a second stage. With a biological filtration, the BIOFIT®.F process from H+E, the fragmented materials are eliminated; what remains is carbon dioxide (CO2) and water as well as very little biomass.

As an alternative, the cracked waste water can be fed back into an upstream biological system where it is also cleaned.

In total, the AOP process from H+E GmbH more than halves the energy and ozone requirements.

Moreover, the production of ozone from pure oxygen and energy results in a large quantity of remaining oxygen. Under particular catalytic boundary conditions, this supports the direct oxidation process. In any case, this is also used for the supply of oxygen to the biological process, thereby also raising the overall economic performance of the process.

Since this reduces the production of ozone-oxygen mixture, the operating costs and the environmental emissions of the process decrease. In long-term scenarios, despite higher investment costs, the process developed by H+E is lower in overall costs than other AOP processes.

H+E GmbH

70565 Stuttgart

Germany