Latest news from the life science specialists

Achema 2015: Stäubli showcases innovations for the pharmaceutical industry

From June 15 to 19, 2015, Stäubli will be at Achema, the international trade fair for the process industry, demonstrating pioneering robotic solutions for life science applications. The focus of interest will be on the new six-axis machines of the TX2 series and especially on developments in ultra-fast packaging with the TP80 Fast Picker of which there are various special-purpose versions on the horizon.

When the issues of speed and accuracy come into play alongside factors such as particle emissions, easy-to-clean surfaces and maximum availability, Stäubli robots serve as the benchmark and have done so for many years. These high-speed, high-precision machines are the first choice in the manufacture of medical devices, pharmaceutical production, biotechnology, laboratory research and hospital automation. Whether for use in a gray, white or sterile environment, the broad range of SCARA and articulated robots on offer means that the optimum machine can be found for every application.

Cleanroom compatibility is one of the basic requirements for any robot that is to be used in these highly sensitive areas. Yet even the standard SCARA and articulated kinematics from Stäubli are suitable for use in cleanroom environments. And they can also be lubricated with H1 food grade oil (Class NSF) without sacrificing performance.

For higher cleanroom classifications and special requirements, Stäubli offers dedicated cleanroom variants, HE versions and Stericlean robots.

New special edition Fast Pickers

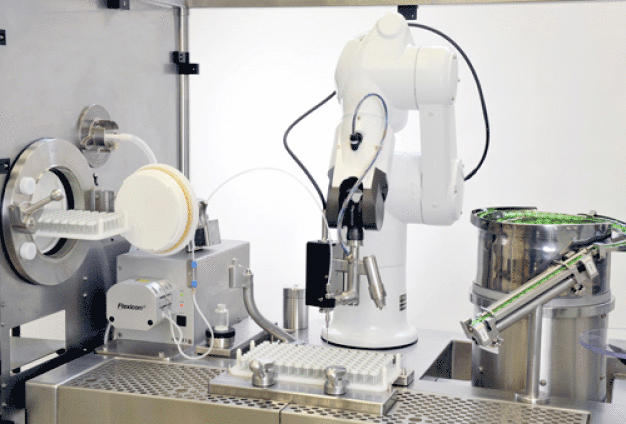

The Stäubli TP80 Fast Picker sets standards for ultra-fast packing and sorting. The innovative four-axis kinematics cope with over 200 picks per minute, handling weights of up to 0.1 kilos. Even at higher loads, the performance of the Fast Picker is barely diminished. At the same time, the Fast Picker has been systematically fine-tuned for reliability and precision. The four-axis machine can operate across large work spaces with a diameter of 1.6 meters, achieving an impressive repeatability rate within ±0.05mm. This makes it ideal for primary and secondary packaging processes which require exceptionally short cycle times.

Stäubli CEO Gerald Vogt points out other key selling points for the machine over and above its superior all-round technical performance: “The Fast Picker has been systematically designed for life science applications. This four-axis robot can be lubricated with food grade oil without suffering any loss of performance. It is easy to integrate and does not have to be mounted on the ceiling directly above sensitive pharmaceutical products. In response to numerous customer requests, we will soon be releasing two attractive special editions – a HE version and a variant with a 200mm quill.”

Up to now, the only HE models have been in the six-axis range. The additional designation “HE” stands for Humid Environment and distinguishes robots which have been modified to make them suitable for use under the most stringent hygiene specifications. The TP80 variant with its 200mm quill significantly boosts the capabilities of the standard model with 100mm Z displacement.

TX2 – a new generation of robots

At Achema, Stäubli will also be presenting its new TX2 six-axis series. The robots on show are significantly more powerful than their predecessors: they are faster, more flexible, more efficient, safer to operate and able to work hand in hand with a human workforce.

Gerald Vogt explains the capabilities of the new TX2 six-axis generation and what the Redefining Performances program involves: “Redefining Performances means that we have thoroughly tested and upgraded all the performance characteristics of our six-axis robots. The aim was to improve the robot in every respect, to integrate superior safety technology and to create a package that would be a technology leader. We wanted to build the best Stäubli robot ever, and that’s precisely what we’ve done.”

The advance in performance is not immediately apparent from looking at the new six-axis robots of the three series in question, namely the TX2-40, TX2-60 and TX2-90. On the contrary, they do not seek to hide the genetic material they share with their predecessors, although they do look more streamlined and dynamic. They retain their ultra-compact design, but now with even slimmer contours. This makes these models – which can cope with a load range from two up to 15 kilos over ranges of between 515 and 1,450 millimeters – the robots of choice for applications where space is limited.

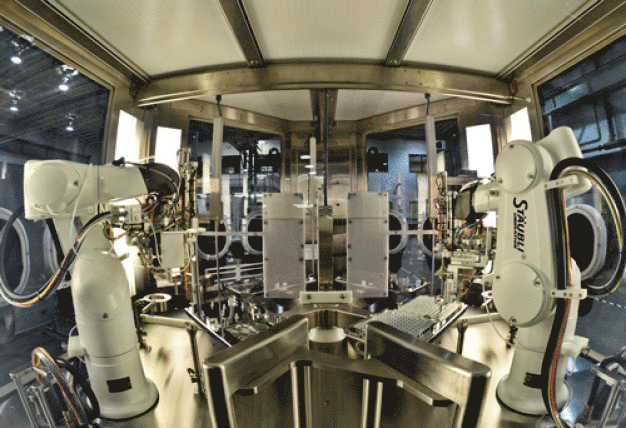

Robots for germ-free processes

Stäubli also has a solution for the automation of aseptic processes. With the development of the world’s first Stericlean robot several years ago, the Swiss manufacturer succeeded in automating processes in the medical and pharmaceutical industries where the use of robots had previously been deemed impossible. Thanks to its advanced construction, the Stericlean robot is able to work non-stop in Vaporous Hydrogen Peroxide (VHP) environments. This proved to be a breakthrough for robot-based automation under aseptic conditions.

Since then, the range and capabilities of Stericlean robots have been steadily expanded. The machines are characterized by a sophisticated enclosure and comply with protection class IP67. Highly stressed parts are fabricated in stainless steel. Before the robots get their paint finish, the surfaces are subjected to a special treatment which increases their resistance to corrosion and ensures reliable operation in VHP environments. All Stericlean six-axis machines comply with the strict Good Manufacturing Practice (GMP) guidelines. In this way, Stäubli has raised its profile as the world’s leading partner for the automation of aseptic processes.

Stäubli Tec-Systems GmbH Robotics

95448 Bayreuth

Germany