STÄUBLI Tec-Systems GmbH

Complete solutions for the food industry

The high performance, dynamism and consistency of Stäubli robots has made them a benchmark in the food industry. In recent years, the Swiss manufacturer has invested heavily in pioneering improvements and new developments to meet the sector-specific requirements for the many and varied applications in food processing.

"We at Stäubli currently offer by far the broadest and most powerful assortment of robots for the food industry," says Gerald Vogt General Manager Stäubli Robotics Germany confidently. He should know, as prior to his appointment in mid-2014 to the Stäubli Management, he spent many years directly supervising the development of robotics at the main factory in Faverges.

The machines that emerged from this period are now regarded as the reference point for food applications of all kinds. Stäubli has the right solution for every task, from straightforward primary or secondary packaging to ultra-fast handling processes and operations involving covered and uncovered products under the strictest hygiene conditions. The extensive range of picker, SCARA and six-axis kinematics can be configured into various versions designed for special applications.

Identification of the right robot for the job can quickly be performed by reviewing the profile of the relevant application. Important parameters may be cycle times, range and payload, hygiene requirements, ability to cope with cleaning processes and so on. Once these criteria have been clarified, the choice of optimum kinematics - SCARA, six-axis or picker - is generally obvious. It then remains to select the appropriate special version.

Abundant special designs

Stäubli robots can be adapted for the most diverse of foodstuffs - bread, pasta or cakes, meat and fish or dairy products, frozen foods or fruits and vegetables - and for a variety of processes - filling, dispensing, cutting, handling, labeling, sorting, packing and palletizing. The big advantage here is that the entire Stäubli robot range can be lubricated with NSF H1 food grade oil which has been developed in close collaboration with a specialist partner company to meet the specific requirements of the Stäubli robot drives and to prolong service life to the absolute maximum. Furthermore, the dynamics of the robot are not impaired in any way: they can attain maximum performance with H1 oil and are not subject to the sort of restrictions that apply to machines supplied by other manufacturers in the market.

After making the decision on whether to use H1 oil, the next choice is between standard, cleanroom or HE specification. Gerald Vogt: "To exclude the growth of bacteria and molds, the production and processing of foods is increasingly taking place in cleanroom environments conforming to ISO Classes 5 to 8. It is therefore a major plus point that even the standard versions of Stäubli robots are cleanroom compliant. If the standard models are still not within spec, optional cleanroom versions can be supplied up to ISO2."

Cleanroom versions for germ-free production

The fast SCARAs of the TS series equipped with bellows conform to ISO 6 cleanroom standard. These high-precision machines boast a repeatability rate of ±0.01 millimeters and are ideally suited for a widest range of applications in the food industry thanks to their smooth, easily cleanable surfaces, their cleanroom compatibility and their excellent performance.

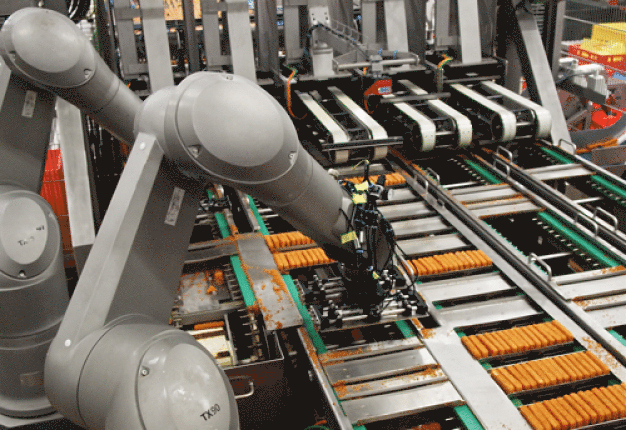

With the six-axis robots of the TX and RX series, Stäubli has taken cleanroom compatibility to the next level. All six-axis robots are characterized by their unique, fully enclosed design with internal cabling and integrated drive technology. As a result, the robots are easy to clean, and even the standard version complies with ISO 5 cleanroom specification. The designated cleanroom versions of these robots are distinguished by the CR suffix and comply with ISO 4. The so-called "Supercleanroom" class of certain six-axis models in the TX series has been upgraded to ISO 2 and can be deployed in virtually germ-free processes.

HE robots: Benchmark for strictest hygiene conditions

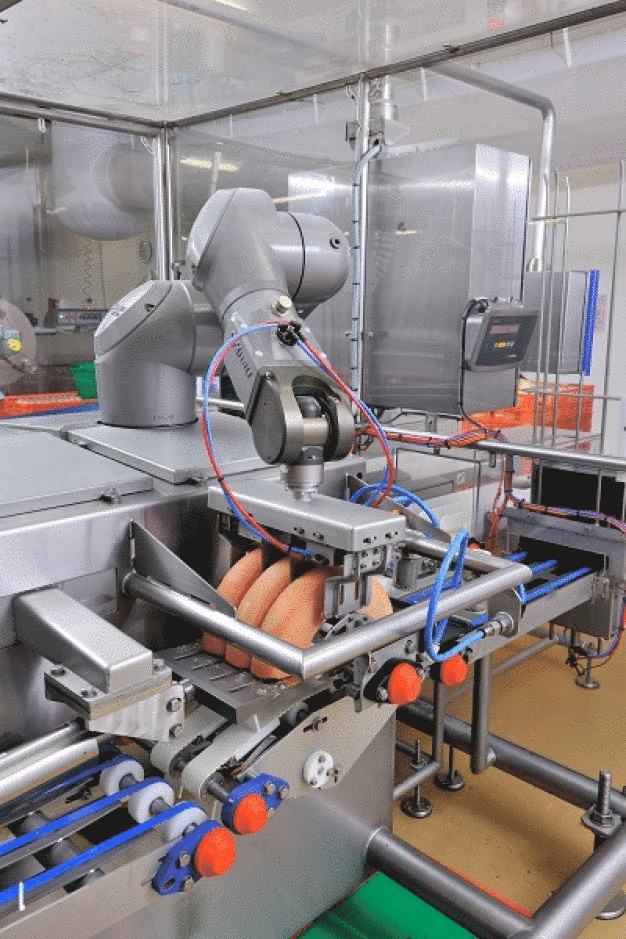

Proving especially popular in the food industry are the HE versions of the Stäubli robots which are able to handle loads of up to 150 kilos. The additional designation HE stands for "Humid Environment" and signifies Stäubli models which have been specifically modified for use in damp areas or are exposed to spray. They are also in great demand for applications that call for the most stringent hygiene conditions. HE robots successfully cope with the daily round of cleaning processes; whereas the aggressive treatment would soon finish off a conventional robot, the HE versions carry on operating with their customary reliability.

"Without our HE robots, it would be impossible to automate certain food applications whilst complying with the strictest hygiene specifications," adds Vogt. "They require intensive cleaning and sterilization processes which no other robot would be able to withstand over a lengthy period. With the HE machines, we have been able to open up new horizons in the food sector, contributing significantly to higher productivity and making the factory environment more worker-friendly."

High-speed picker for sorting and packaging tasks

Another superlative has been claimed by a new high-speed robot developed principally for sorting and packing applications in the food industry. The TP80 Fast Picker achieves a pick rate of more than 200 per minute, thus paving the way for new concepts and strategies in the handling, sorting and packaging of foodstuffs. Gerald Vogt: "The Fast Picker has been designed specifically for applications in the food industry. It is easy to integrate and does not have to be ceiling mounted directly above the sensitive foodstuffs passing underneath. We are also bringing out an HE version in the very near future."

The Fast Picker has been fine-tuned for uncompromising reliability and precision. The four-axis machine can operate in large work spaces with a diameter of 1.6 meters and achieves an impressive repeatability rate of ±0.05 mm. High precision is maintained even after many thousands of operating hours.

Complete solutions in focus

Used in conjunction with the new LINEmanager load-sharing software, the TP80 is a formidable complete solution. The tool has been designed for highly complex picking, sorting and packaging tasks where a 100% reliable solution is required for multiple robots working on a single conveyor belt. The software package manages the complete synchronization of the line by coordinating the speeds of all the robots as well as the feed and discharge belts.

Stäubli has further software solutions on offer for the food industry, allowing users to easily operate the robot components as well as the programming of the entire production line.

Gerald Vogt: "With the introduction of the HE series, the launch of the TP80 Fast Picker and innovative software solutions, Stäubli has further consolidated its leading market position in the food industry. For Stäubli, the food sector is now a hugely important market on which we continue to focus strongly. Working in partnership with producers, we aim to promote automation in the food industry with yet more pioneering developments, thereby improving safety, efficiency and productivity."

Stäubli Tec-Systems GmbH Robotics

95448 Bayreuth

Germany