Jim Polarine & Marc Rogers

Fungal Spore Contamination Control and Residue Removal in Cleanrooms

Residues

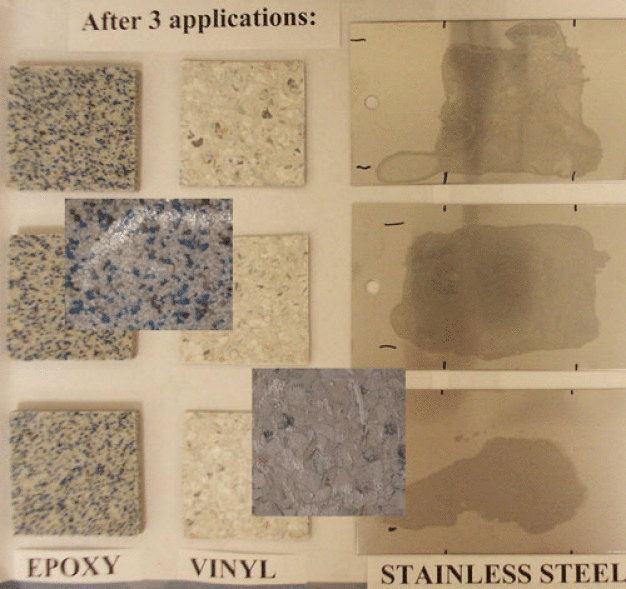

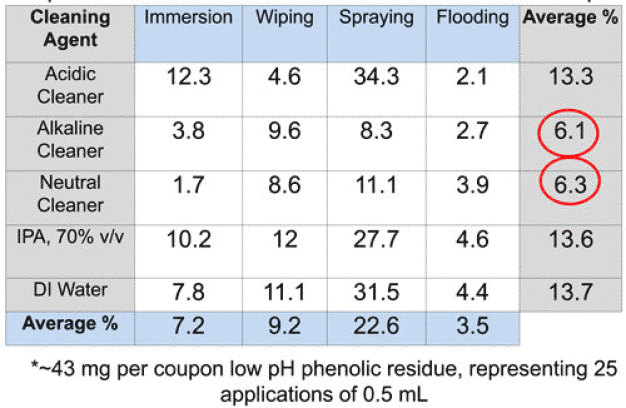

Disinfectants and sporicidesare critical for microbial contamination control within pharmaceutical, biotechnology, and medical device industries. However, their regular repeated use can result in build-up on disinfected surfaces over time. These residues are potentially problematic from visual, safety, and product integrity perspectives. Residue is most apparent (and becomes visible to the unaided eye) at about 4 mg/cm2on stainless steel, but can be difficult to see on other surfaces commonly found in cleanroomenvironments (Fig.1).

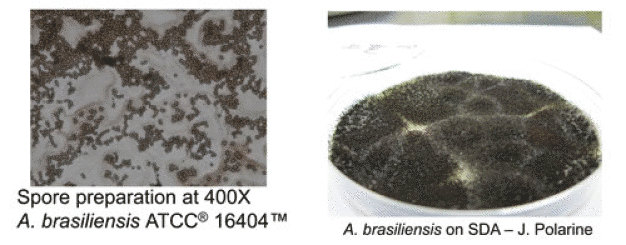

Fungal spore inactivation

Fungal isolates commonly found in cleanrooms:

- Aspergillus spp.

- Cladosporium spp.

- Penicillium spp.

- Chaetomium spp.

- Paecilomyces spp.

- Mucor spp.

- Trycophyton spp.

- Stachybotrys spp.

- Alternaria spp.

- Fusariumspp.

- Rhizopus spp.

- Curvularia spp.

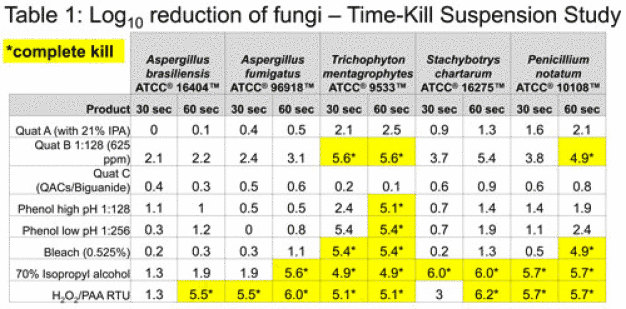

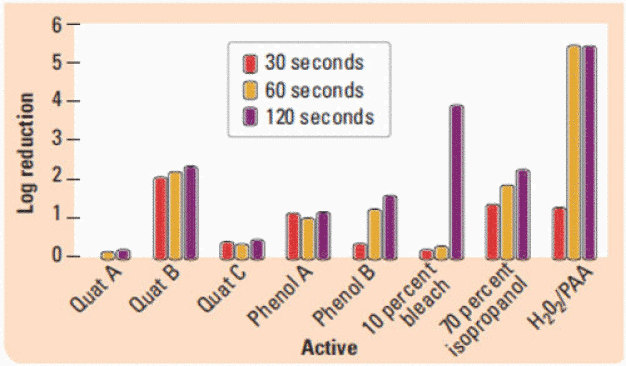

Which product to use for molds?

- Quaternary ammonium formulations

- Phenolic formulations

- Isopropyl alcohol 70% v/v

- Ethanol 70% v/v

- Sporicides

- H2O2/ Peracetic acid blends, H2O2alone, Sodium hypochlorite

Conclusions

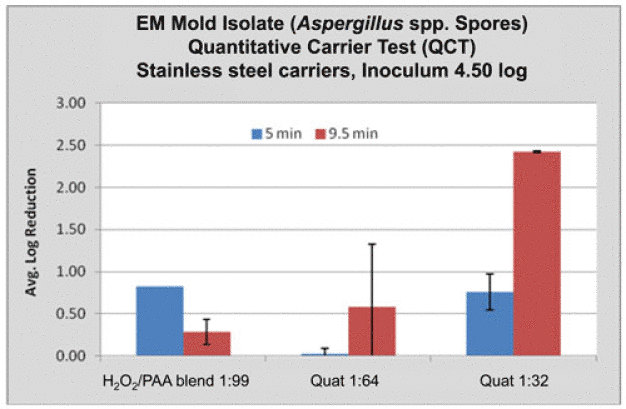

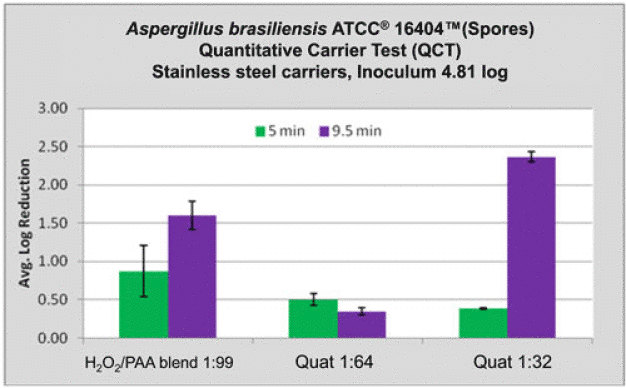

In general, a sporicide is recommended for control of fungal isolates on most cleanroom surfaces. In certain cases (e.g. two log reduction desired), quats or 70% IPA may be used. Results can be strain-specific and surface-specific, so in vitro coupon (surface) testing is advised.

Residue removal is necessary for a complete cleaning and disinfection program and should be performed as needed based on visual or tactile observation.

For further reading see: http://www.ivtnetwork.com/article/jim-polarine-and-marc-rogers-rinsing-strategy.

Acknowledgements

We thank Carol Bartnett for fungal inactivation data and Brook Meadows for residue data and photos (Fig. 1, Table 1).

STERIS Deutschland GmbH

50933 Köln

Germany