With an IML/IMD combination for a multi-touch display – without a compression zone with an SL plasticising assembly for higher precision

Sumitomo (SHI) Demag at K 2013: function integration and precision injection moulding – focus on high added value

With innovative technologies and production processes implemented in complex and fully automated injection moulding cells, as well as highly precise, dynamic and energy-efficient injection moulding machines, Sumitomo offers system solutions with high added value for various industry applications.

For the first time, a fully automated IML/IMD production cell, producing a 5‘‘ multi-touch display in one single step, has been presented at the K trade fair in Düsseldorf. For the first time also, the SL plasticising assembly that operates without a traditional compression zone and thus offers advantages compared to conventional plasticising assemblies has been presented in Europe. In addition, the company has demonstrated the performance spectrum of an all-electric IntElect by running various applications.

Injection moulding cell for multi-touch display – IML for function, IMD for decoration

The production of a multi-touch display, for the first time in a 5‘‘ size – equivalent to a modern smartphone – by injection moulding with a Systec 210 (clamping force 2,100 kN) is evidence of Sumitomo’s competence in complex, fully automated injection moulding cells for efficient and reliable mass production of innovative products. An example of a mass produced part that has been presented at the K trade fair stand is functional films overmoulded with PMMA as part of an in-mould labelling (IML) process developed by PolyIC GmbH & Co. KG, a Kurz Group company. The narrow frame produced by the same procedure is additionally decorated using in-mould decoration (IMD) with a sleek black finish. All operations, from insertion of IML film into the mould cavity through the final multi-step post-processing process for displaying the assembly, take place in the production cell in a cleanroom atmosphere (class ISO 7).

Conductive IML films optimised by PolyIC for injection moulding (so-called PolyTC films) are PET-based films covered with thin metallic conductor structures. They can replace many films currently used for touch screens, for the most part consisting of indium tin oxide (so-called ITO films). ITO alternatives are interesting not only from a technical viewpoint, but also from an economical one, since indium is a rare heavy metal, the price of which continually increases with a growing demand. In addition, the costly lamination of the carrier with film can be omitted. It is already apparent that touch screen technology will be increasingly utilised in the future, and not just in communications technology. Versatile fields of application range, in particular, from the automotive industry and consumer electronics down to white goods for the diverse operating functions required for each specific task.

Even with their individually customisable layout, PolyTC films from PolyIC can be manufactured cost-efficiently as a mass produced product. At the same time, these functional films can be used as individual labels applied during the IML process. Thus, the injection moulding process can be used to efficiently and directly apply touch sensor functionality to large-scale production components.

The IML/IMD production cell with a Systec 210 at a glance: For the IML/IMD combination presented at K 2013, Sumitomo and several specialists designed a modular system centred on the hydraulic all-rounder machine, the Systec. Besides PolyIC (for functional film) and Leonhard Kurz Stiftung GmbH & Co. KG for IMD decoration film and IMD film handling, partners include HBW-Gubesch Kunststoff-Engineering GmbH as developer of the mould, SAR Electronic GmbH as system integrator for the robot-supported automation; Max Petek for the cleanroom solution; and Kist Maschinenbau GmbH as supplier of the modules for the UV film hardening and cleaning of finished parts.

The central switch point in the injection moulding cell with the Systec 210 is a suspended industrial robot (TX90 from Stäubli), equipped with a three-sided gripper system. It extracts one conductive in-mould label (PolyTC-Label) per cycle from a stack and positions it exactly onto the fixed half of the single-cavity mould. Simultaneously, the IMD feeder, installed on the clamping side above the mould mounting area, brings a carrier film with individual pictures to the decorative coating of the moulded part and positions it exactly inside the cavity. Once the mould has been closed, the PMMA display is injected through an auxiliary gate; the shot weight is 20 g. This process uses the variotherm mould temperature control developed by gwk Gesellschaft Wärme Kältetechnik mbH.

The variotherm mould temperature control is extremely important for the reproducibility of consistently high product quality, in particular for long and narrow flow paths inside the mould, e.g. for an injection-moulded multi-touch display. During this process the mould wall is temporarily heated to a temperature between glass transition temperature and melting temperature of the utilised plastic. This increased mould wall temperature delays or prevents melt solidification as early as during injection, preserves its flowability through constant low viscosity until the mould is completely filled, and thus reduces the required injection pressure and consequently the clamping force. Mould cooling does not start until the cavity has been completely filled and lasts until the part has reached demoulding temperature. While cooling down, the even mould fill extends hold pressure due to an improved pressure distribution in the areas located far from the gate. As a result, all mould areas require the same cooling time. This reduces the risk of deformation as a result of contraction, and at the same time, improves part size accuracy and consistency. In addition, this process is especially well suited for the production of particularly smooth finishes and high-quality glossy finishes. All these advantages of variothermal injection moulding will also be observed in the Systec cell during the combined IML/IMD injection moulding of the touch screen display and frame with its glossy finish.

Even though injection moulding itself forms the basis of the process, the subsequent steps that take place outside the mould within the cycle time of 40 s contribute considerably to the component quality and its cost effectiveness. Once the six-axis robot has removed the display frame from the mould and inserted a new label, it places the component onto a work carrier. The component is then transported into an enclosed laser separation station, where a CO2 laser with air extraction accurately removes the film sprue without breakage. The robot then brings the display into a UV curing unit to cure the finish coat of the decoration film. From there the component is transferred to the cleaning station located below the UV station for the final processing step. Here, brushes perform the meticulous and gentle removal of any remaining fragments of IMD film; any particles loosened from the edges are extracted, leaving no residue.

Production in a cleanroom is absolutely essential for the reliable operation of the multi-touch display. This is ensured by a laminar flow module that cleans the incoming outside air and prevents penetration of particles through a FFU (Filter Fan Unit). Thus, an air purity of ISO class 7 is reached. However, the overall concept of the cell clearly exceeds basic requirements – with the cleanroom module above the injection unit and with protective enclosure profiles and surfaces that can easily be cleaned. All subsequent post-processing steps, such as degating, UV curing and cleaning, take place in sealed system modules closed off from the mould mounting area of the injection moulding machine by partitions.

The entire production cell is constructed modularly. This allows modules to be added or removed depending on the desired degree of automation. In addition, a standardised interface between the moulding machine and automation equipment ensures short commissioning times and a high level of flexibility. Faster commissioning and a reduction in equipment complexity are also helped by the fact that a single industrial robot performs all the handling tasks of the entire production cell. Due to the suspended mounting of the six-axis unit and the compact automation enclosure, the footprint of the entire cell is very small.

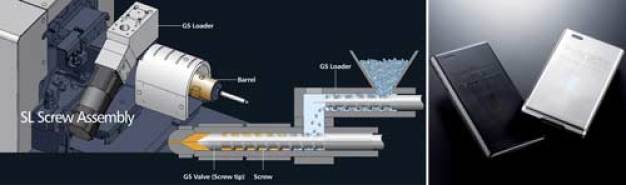

The new SL plasticising assembly – compression-free plasticising brings advantages for process stability and product quality

The important feature of the new SL (Spiral Logic) plasticising assembly, presented by Sumitomo at K 2013, that sets it apart from conventional plasticising assemblies of an injection moulding machine is a cushioned plasticising screw operating without a compression zone. The material is fed by an upstream dosing screw in a controlled manner. The optimum filling ratio is defined based on the material properties and process parameters. The added granulated plastic is melted almost exclusively by the easily adjustable heat supply from the plasticising unit barrel heater.

Compared to conventional plasticising assemblies, the SL assembly offers clear advantages. The crucial feature here is that the regulated operation generates a very homogenous melt without viscosity variations. This results in an obvious reduction in process variations and thus variations in product quality. Due to controlled feeding and operation without a compression zone, high pressure peaks and blockages from nonmelts in the feed zone are avoided, in contrast to cases where such problems occur in the compression zone when conventional screws are used, in particular, when semi-crystalline plastics such as polyamides and PBT (polybutylene terephthalate) are processed. At the same time, due to the lower friction of the SL assembly, wear in the feed zone of the plasticising unit is clearly reduced. Additional advantages of gentle material handling are a low degradation level, a lower reduction in fibre length, longer mould cleaning intervals and energy-related benefits.

In combination with a switchable non-return valve, the compression-free screw has a particularly positive affect on the production of technical precision parts. The SL plasticising assembly is also beneficial if product cleanliness requirements are high, e.g. for moulding of optical parts. Due to the removal of the compression zone, the deposits on the screw that are usually unavoidable can be drastically reduced. These deposits flake off and appear as black spots on the parts. Longer cleaning intervals not only reduce the amount of the reject rate, but also increase the machine availability for applications, even if part cleanliness requirements are high.

The SL plasticising assembly is currently only available as an option for all-electric SE-EV series machines produced by Sumitomo with a clamping force range of 500 to 1,800 kN. The new assembly will be presented at the K trade fair on an SE 180 EV (clamping force 1,800 kN). The machine will produce cases for a smartphone made of a ABS/PC blend using a 2-cavity mould; the shot weight is 45 g, the cycle time 25 s.

Precision injection moulding – a domain of the all-electric IntElect

Safety, process consistency and precision for demanding applications with the narrowest tolerances are the main characteristics of the all-electric IntElect series. Similar to the SE series, the IntElect also uses electric direct drives developed and optimised for the injection moulding process and produced by Sumitomo. In contrast to the belt-driven electric drives, these direct drives offer a high level of energy efficiency and ensure higher precision with their faster response times, higher reproducibility and even a cycle time advantage. Thus, the company's electric machines particularly meet the requirements for injection moulding of high volume precision parts.

Balanced multi-cavity moulds: At the stand at the K trade fair an IntElect 100-340 (clamping force 1,000 kN) produced the complete set of parts for a key housing (smart key) made of a PC/ABS blend; the cycle time is 30 s, the shot weight is 33 g. The special requirement for this family mould with large differences in cavity volume is that it should be reliably filled shot by shot. This is why the additional technology module activeFlowBalance is used. The machine at the trade fair stand vividly demonstrated how deactivation and activation of activeFlowBalance affects the demoulding of parts in individual mould cavities. The 6-cavity mould is designed for two upper and lower parts of the housing, as well as for the clearly smaller button switch.

activeFlowBalance can be used to successfully balance out the uneven and fluctuating balancing of multi-cavity moulds which usually leads to negative effects, such as burr formation, underfilling and mould damage. When changing from injection pressure to hold pressure, this machine function uses the expansion of the compressed melt, whereby the partially-filled cavities are filled better due to their low counter pressure. The fill levels balance out in a natural way without extending the cycle time.

Suitable for the cleanroom: The IntElect 50-45 (clamping force 500 kN) will be used to produce MABS components for a peripheral intravenous catheter with a cycle time of 9 s. This application demonstrates precision injection moulding with a hot-runner connection and multi-cavity mould, as well as the cleanroom suitability of the IntElect. The requirements of ISO class 7, which often apply to the production of medical products, can be easily and reliably be met. The only requirements are the mounting of a laminar flow box above the clamping unit and the installation of the machine in a clean environment (cleanroom).

The IntElect 50-45, in conjunction with three other machines at the trade fair stand, was equipped with MAS software developed by T.I.G. Technische Informationssysteme GmbH to record, visualise, analyse and monitor operation, production and process data in real time, even for a large number of machines. Sumitomo contributed as a partner to this new development that has been presented at the K trade fair. The traceability functions of the software allow the user to trace back the product-relevant information down to each individually manufactured product. This requirement continues to grow, particularly in the medical and automotive industries.

The company was also represented with two other all-electric machines at partner stands. An IntElect 100-340 (clamping force 1,000 kN) produced PP blister packages at the trade fair stand of Yushin Precision Equipment Co. Ltd. At the stand of Stieler Kunststoff Service GmbH an IntElect 50-110 (clamping force 500 kN) produced a radio cover for an automobile interior. The focus here was on the finish quality of this demanding visible part. A special combination of different injection moulding techniques (temperature control, external gas pressure process and CO2 cooling), which have been developed by Stieler, has been used. This process can be used to produce high-quality, reliable finishes.

Sumitomo (SHI) Demag

90571 Schwaig

Germany