Racking and packing � by quality to the world leaders

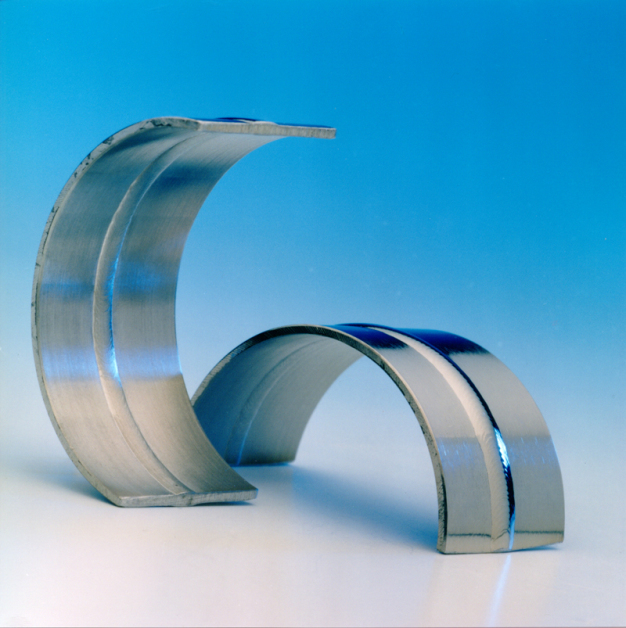

Before nearly 60 years as manufacturers for labelling machines started � today market leaders in things system engineering: The Krones AG, Germany, plans, developed, manufactures and installs world-wide plants for the filling up and packing method after High Purity standard. Customers around the globe are approximately breweries and beverage manufacturers, food, chemical, pharmaceutical as well as cosmetic Industrie.Die of reasons for success are various, let themselves however easily on the denominator � quality, reliability and service � be brought. � criteria, those in our house also for each production step are valid �, thus for Anton Hirschberger � technology advisors and project managers for all interests approximately around welding with Krones.Zur demanded quality of the high-grade steel welded joints after European and American set of rules come recommendations, regulations and standards for the condition of surfaces, the late contact with the customer products like e.g. Beverages or medicines have. The most important defaults for this come from � the Guidelines � derEuropean Hygienic engineering & Design Group (EHEDG) and naturally from the classical standards of the American Food and Drug administration (FDA). Smoothly and these regulations require a hygenic, and/or aseptische, sterile and particle-free execution of the surface, so smoothly and cleanly apart from the mechanical properties for the welding seam also that them can be cleaned with automatic cleaning methods (CIP) arrearsless and thus neither product remainder to adhere nor germs to settle be able themselves. � characteristics, those when welding the high-grade steel fittings usually only with the automated tungsten inert gas (TIG) - orbital welding to fulfill are �, holds Anton Hirschberger. This technology already held in the production plants of Krones before 23 years introduction. � we have the crucial components of the orbital sealing machines � power source, control, welding tongs � most diverse offerer tested �, remember the specialist with the little charming official job title � welding supervision � � and it continue, � are our realization all in all that one of the best plant packages � and for this not least also the service counts and the advancement of welding tongs comes � from Polysoude, Nantes, France. The decision for a supplier in all production plants affects itself in addition also positively the productivity and flexibility out, there we for the availability, procuring wearing parts, the consultation, as well as the customer service essentially only one partner have �. For special cases ger�stetIn its plants e.g. processes Krones a multiplicity of pipes with most different lengths, diameters and wall thicknesses � the output pipe. according to the DIN 11850 � the qualities: to 1.4404 � ASTM 316L and/or 1.4301-entspricht ASTM 304.F�r the tubing welded joints in the work corresponds to Neutraubling is altogether to 10 orbital sealing machines at the disposal. The enterprise designed the devices for handling of the welding building group in addition and in detail to the welding task cut: depending upon accesibility, weight, measure as well as more or less complex geometry of pipes or fittings. The high-quality welding at the pipes with diameters from 12 to 115 millimeters mainly with closed welding tongs are accomplished. In addition, open welding tongs are used. Further orbital plants of the same type are used in the works Nittenau, Flensburg and Freising. For welding tube heat exchangers the system tubing in ground in the work Flensburg is used. Five works, all operators of Orbial sealing machines received their basic qualification by Polysoude briefing and locked the qualification with an operator examination according to DIN EN 1418. Over it they are instructed in the house Krones in the extensive additional set of rules defaults. � our machines and plants must become fair innumerable industrie and welding standards, in addition come customized regulations �, describe Hirschberger, � all these defaults to have we in a Krones company standard converted. Beside the classical defaults from the welding standards e.g. ISO 5817 and/or ASME seconds. IX we summarized all criteria for the welding seam quality. To the well-known " Permissible Unregelm��igkeiten" the annealing colors and a statement are given to the surface of seam. � the advantages are on the hand �, explain the welding expert, � after this default we manufacture in all five German works with the same quality; it has validity for all fusion welding procedures at steel, titanium and their alloys. � enormous influence on Qualit�tDie demand for quality products, rising world-wide, � larva in Germany � is unbroken. With this trend also an expansion of the manufacturing capacities with ever high-quality materials accompanies. For the lasting success of the Krones AG this means to be always also in things technology outrider. Hereunder applies it not to leave apart from the productivity also the quality from the eyes. � from there it the automated TIG orbital welding of the tubing components ever more meaning too �, summarizes Hirschberger comes, � the procedure of Polysoude has enormous influence on the quality and only this supplies the demanded cleaning-fair, smooth welding seams, with a seam root, which locks concisely with the tubing inner wall, a minimum heat bringing in with smallest oxidation, those by pickling if necessary is easily removable (a metallically bright inner wall is a condition for the natural passivation process, which protects the surface permanently). In addition come the unsurpassed metallurgical characteristics, which fulfill each still so strict standard to more than. � all factors, which are indispensable for the germ-free production of beverages, food, medicines as well as Kosmetika.

This text was translated automatically.

POLYSOUDE S.A.S.

44300 Nantes

France