Sensors for the measurement of the electrolytic conductivity of pure and high-purity water

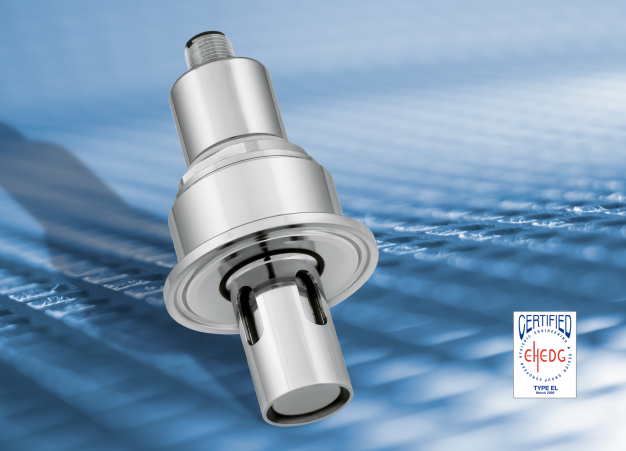

In the context of the extension of the successful JUMO tecLine Lf VA row after type sheet 202924 two new Messzellen (K = 0.1 and K = 0.01) were developed. By a shortening of the active test electrodes they permit the installation even with smaller pipe diameters and/or sample volumes. The choice of materials and the technical organization of the sensor in accordance with the Hygienic Design defaults of the EHEDG, attention of the Regularien of the ASTM international and the European pharmacopeia (pH. Eur.) were defaults with the construction of the sensor.� Thus the sensor can be used in plants for the production of high-purity water for the industries pharmacy, food and biotechnology. In addition, due to a good price performance ratio the employment is conceivable in pure and high-purity water plants for technical rinsing processes (reverse osmosis plants, Ionentau). During the measurement of pure and high-purity water with conductivenesses of approx. 0.05 �S/cm (18.3 M�) to approx. 500 �S/cm is used konduktive conductance sensors to the 2-Elektroden-Prinzip. Crucially for the best results of measurement are here the cell constants of the sensors. So compellingly a Messzelle with cell constant K = 0.01 must be used for the measurement of high-purity water of highest quality (under 1 �S/cm). Within the range of 10 �S/cm upto max. approx. 500 �S/cm cells come� with K = 0.1 to Einsatz.Die of medium-affecting parts are manufactured made of high-grade steel 1,4435 (316L) in electricalpolished quality. For it certificates of acceptance test know 10204 3,1 as well as Rauigkeitszertifikate after EN (better 0,8�m in accordance with pH. Eur. and/or ASTM international) to be made available. The used seals and plastics correspond to the requirements of the FDA and are physiologically harmless. The cell constant can be measured and confirmed with ASTM test certificate. This is in particular with Pharmawasseranlagen of importance. The electrical connection is made by M12-Stecker. For temperature collection a Pt1000, is integrated class A. The sensor was equipped with the JUMO PEKA Prozessanschlusssystem. This possesses a EHEDG permission and is sufficient thereby for the highest requirements for hygiene. Owing to the modular system structure the sensor existing in camp execution can be equipped fast with each process connection wished by the customer. The suitable adapter (e.g. Clamp, VARIVENT�, milk cone, Einschwei�stutzen) is screwed as module on the sensor.

This text was translated automatically.