Pure area is not equal to pure area

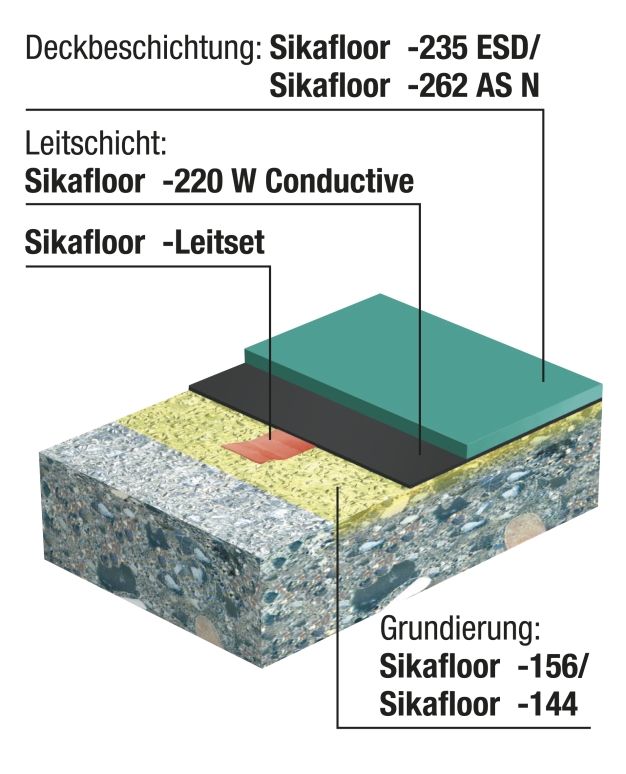

Sika offers comprehensive solutions for specific requirements the final surrounding field of a pure area is subject to strict and constant control. The sense of word accordingly, air must be as clean and unloaded as possible. In order to keep the particle contamination and the concentration of airborne molecules small, different techniques come to the employment: Protective clothing, air cleaner as well as abrasion-resistant, ground, winding which can be cleaned easily and cover coatings. Pure areas are today in many industries indispensable and the need grow. Particularly in electronics and computer industry, in pharmaceutical companies and with the manufacturing of food and luxuries they come to the employment. In addition, in the motorring industry, the medical technology, in operating rooms and air and space technology pure areas play an important role. So differently the operational areas are so different, are also the requirements to the pure areas themselves. In order to guarantee smooth as well as safe work and production processes, branchspecific conditions must be considered regarding the emission rate. According to the individual requirement of a pure area the Sika Germany GmbH offers complete coating solutions for grounds, walls and covers in accordance with the special requirements to the different ranges. The broad pallet of clean-spacesuitable products and systems fulfills general requirements like nonporous and jointless as well as surfaces which can be cleaned easily. The small AMC and VOC degassings and the minimum emission of particles of the Sika products guarantee that the contamination is kept particularly small by materials and devices. Process security is higher and the finished products is purer, whereby productivity and quality of the manufacturers rise. On the basis of the use of the high-quality ground and wall coatings, the further pure spatial planning becomes extremely economical concerning ventilation, cleaning, maintenance. Also the stability of the coatings against chemical, thermal and mechanical attacks is very highly � and over years, because the products of Sika are characterised by a high life span. The fast processing provides for short down-times with repairs and for one time near start-up with new buildings. In addition a large selection of colors stands to order over the basic requirements outside depending upon need determined characteristics such as derivation ability, tear bypass or chemical resistance is fulfilled. All solutions are in any case extremely economical. The basis of most Bodenschichten is a priming with an epoxy resin, for example Sikafloor-156 or also the allergy-reducing Sikafloor-144. Unevenness in the ground become balanced by laying these two EP-primings on in the form of screeding compound. The upper cover coating corresponds to the respective requirements to Reinraumboden.Das Premium product Sikafloor-266 CR comes to the employment whenever high requirements are demanded to the degassing behavior, as well as the particle emission. This coating material for particularly high requirements was developed to room air quality. Sikafloor-266 CR orders as the first product on the market at the same time over a IPA certificate concerning the particle emission (ISO class 3) and over a AMC certification, a material qualification regarding the degassing behavior. Derive-able grounds require a so-called conducting layer between the priming and the surface layer: The conductive paint Sikafloor-220 W Conductive consists of a solvent-free, electrostatically highly derivable epoxy resin and after the transfer over the Sikafloor Leitset to the earth potential is attached. Over it Sikafloor-235 ESD is applied as directly usable cover coating for ESD protected ranges. Alternatively for this there is the combination of the running coating Sikafloor-262 AS N and the aqueous EP-sealing Sikafloor-230 ESD TopCoat.�u�erst chemikalienbest�ndige surface layers is the two-component Sikafloor-381 and the elastifizierte Sikafloor-390. The latter is recommended particularly as tear-bridging solution. There are both epoxy resin products also in derivable versions: Sikafloor-381 AS and Sikafloor-390 AS. An economical and at the same time attractive solution for cover application is the universally applicable epoxy resin bonding agent Sikafloor-261. It is abrasion-resistant, and in many colors available. Walls, columns and covers in pure areas need as a rule a priming for the catch of the pores in the concrete and a cover coating. For the reconciliation of the irregularities can be used the process-finished, well responsible screeding compound Sikagard-185 Porefiller. In addition, adjusts unevenness for the putty Sikadur-331. Subsequently, the upper surface layer laid on, for this presents itself the aqueous, two-component coating Sikagard-183 W CR. The EP-dispersion Sikagard Wallcoat N is particularly resistant against chemicals and is suitable also for Waffeltisch covers. Beside the numerous possibilities to the ground coating and the solutions for wall and cover, the Sika Germany GmbH offers also clean-spacesuited products to the protection against corrosion as well as suitable sealing material picture: Derive-able grounds require a conducting layer between priming and the surface layer: Sikafloor-220 W Conductive is appliziert in this case after connection of the points of grounding by means of the Sikafloor Leitset on the priming. Over it depending upon desired protection characteristics the derivable coatings, e.g. Sikafloor-262 AS N or Sikafloor-235 ESD, are laid on.�

This text was translated automatically.

Sika Deutschland GmbH

70439 Stuttgart

Germany