Plastic - laser welding

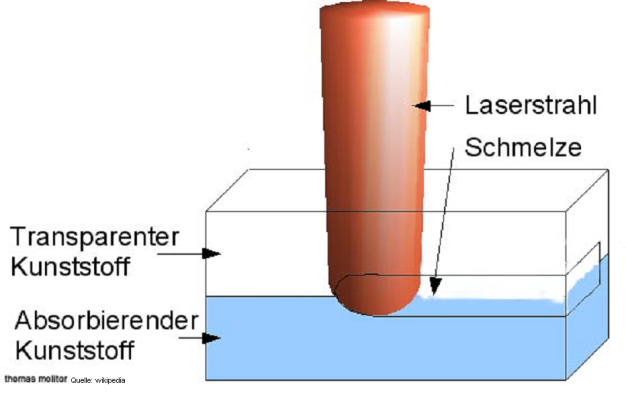

Particle-free working is one of the central requirements to the manufacturing for the medical technology. In particular during the pure space manufacturing it is obligation of each producer to avoid or at least reduce all impurities. This places above all the adding technology before large difficulties. With the employment of adhesives for example is to be counted on unwanted aero brines and steams. These can to be controlled only heavily and be able at unfavorable places in the form of deposits to settle. Besides with the adhesive an additional component item number is used. A increased permission expenditure with registration-requiring medicine products is the result. With the ultrasonic welding however unwanted particles and engineers develop are substantially reduced due to the procedure in the organization freedom due to the friction between the adding partners. Also bringing in the energy represents a larger challenge, the whole construction unit in oscillation is shifted nevertheless and can perhaps damage take. Ideal procedure for MedizintechnikDie method of the laser welding however seems to be as creative for the medical technology: It can be guaranteed by the contactless process that the products are not contaminated by foreign effect. The minimum thermal load of the construction units provides for high precision and reproductibility. Develops no wear of tools, which can draw aufw�ndige maintenance or Requalifizierungen. Besides the brought in energy is brought in very precisely proportioned at the joint, the remainder of the construction unit remains undisturbed by the adding process. This means also the fact that very little warmth is produced which with the work in the pure area under laminar air flow is not insignificant. Further advantages of the laser welding: - Welding seam does not know recording all relevant process parameters inside the construction units put on is been based to possible additives necessary shortest cycle time heating up by absorption of LaserenergieDas principle of the laser welding on the fact that the energy of the point-exactly brought in laser beam is absorbed by the plastic. This entails a local heating up, which leaves the polymer melt opens. It is to be made certain that the heating up arises accurately in the place, where a connection between the construction units is to be made. This is in practice reached, by of the construction units for laser beams, which can be connected, being arranged permeable (transparency) and the other construction unit laser absorbing characteristics exhibits. If the absorbing component warms up due to the radiation energy, owing to the local heat transmission at the joint also the transparent material is aufgeweicht and a homogeneous welding seam between the two construction units develops. A condition for this is natural that both adding partners exhibit a similar fusing temperature. Innumerable AnwendungenAls rule of thumb is valid: � everything that can be welded with ultrasonic, can be welded also with laser �. Accordingly no borders are set to the applications. Frequently the procedure is used to have obvious advantages of the laser welding at present with micro titer plates, surgical instruments, balloon catheters, housings of blood pumps and cartouches for Mikrofluidik.Die Swiss plastic processing plant GEM� Medical induced to invest into this technology. According to specifications of GEM� standard equipment was developed further and guarantees now that the high requirements are at full extent fulfilled concerning pure space fitness. Thus GEM� in the tendency gets ahead to offer complete solutions from plastic a crucial step. Apart from injection moulding, mechanical treatment, rapidly prototyping and assembly now a progressive joining process - in the pure area implemented - can be offered.

This text was translated automatically.

GEMÜ GmbH

6343 Rotkreuz

Switzerland