- Cleaning | procedures, devices, agents, media (Wipers, Swaps,...)

Deep cleaning with implosion force: “Vacuum Impulse Technology (VIT)” pressure change process

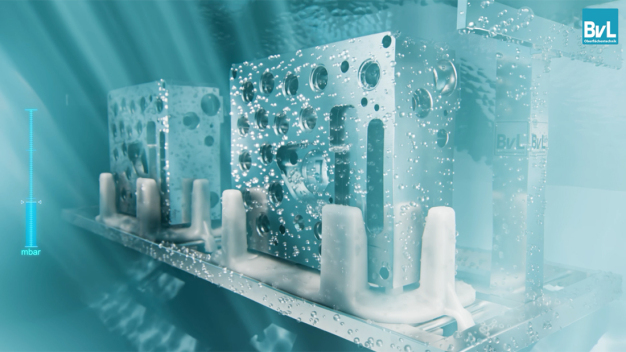

Ideal for the highest cleanliness requirements for precision parts with complex component geometries

When cleaning technical components with complex geometries, conventional water-based cleaning processes often reach their limits - especially in capillaries, deep blind holes or delicate internal structures. For applications with particularly high demands on technical cleanliness, BvL Oberflächentechnik now offers an innovative addition: the pressure change process VIT - Vacuum Impulse Technology.

Typical fields of application in the area of fine/fine grit cleaning and high purity

VIT technology is ideal for industries where the highest standards of technical cleanliness apply - often in the micro and nano range, down to the molecular level. Residue-free surfaces with validatable and reproducible processes are required here. These include companies from the automotive industry, hydraulic and fluid technology, semiconductor production, medical technology and manufacturers and suppliers of high-purity applications. From fuel injection technology in vehicles to ultra-high vacuum technology in the semiconductor industry, there are components with capillary structures in many areas where conventional liquid cleaning processes have so far reached their limits.

While ultrasonic waves work excellently in open media, for example, they reach their physical limits in deep holes, tightly packed bulk material or narrow channels: The waves reflect and lose their effectiveness. This is where BvL's vacuum impulse technology comes in and supplements the cleaning process with a mechanical depth effect that also works where ultrasound cannot reach.

Possible sequence in the cleaning process:

1. vacuum flooding of the chamber - also in preparation for pressure changes

2. ultrasonic cleaning - for degassing the medium and initial detachment

3. VIT - for targeted deep cleaning

More cleanliness thanks to targeted pressure change process

The principle is physically impressive: in a liquid-filled vacuum chamber, the ambient pressure is lowered in defined rhythms and then abruptly ventilated. This creates gas bubbles that are irregularly visible or only microscopically small. When the vacuum chamber is ventilated, they implode - so-called micro-cavitation shocks. These act directly in the boundary layer of the component surface and dissolve even stubborn particulate and filmic contaminants.

The recurring pressure change also creates an asymmetrical volume flow that flushes the cleaning medium deep into structures that are difficult to access and reliably removes dissolved particles. This combined effect enables more intensive cleaning than pure ultrasonic methods, for example - especially in undercuts, capillaries or blind holes. VIT therefore offers an effective and safe supplement to conventional cleaning methods.

Special feature: Vacuum technology

For the VIT technology, BvL relies on a further developed vacuum pump that is particularly characterized by the following features:

– Energy efficiency thanks to optimized pressure control

– Low maintenance thanks to less frequent oil changes and low susceptibility to wear

– Robustness against high steam loads - even with intensive cleaning cycles and/or cycle times

The combination of these properties makes the VIT process particularly economical in continuous industrial use. This sets the VIT process from BvL apart from other pressure change processes.

New deep cleaning technology now available

With the introduction of the Vacuum Impulse Technology (VIT), BvL offers a powerful technology for industrial cleaning tasks that go beyond the standard and thus expands the possibilities of component cleaning with a powerful, precise and economical component. The VIT process is now available from BvL for all vacuum-proof basket systems in the Niagara series and for the Atlantic immersion cleaning system.

BvL at EMO and parts2clean

BvL will be exhibiting at the upcoming EMO trade fair from September 22 to 26, 2025 in Hannover and parts2clean from October 7 to 9, 2025 in Stuttgart in Germany. Trade visitors can find out more about BvL's range of customized cleaning systems here.

EMO: hall 11, booth G24

Parts2clean: hall 10, booth F10.

BvL Oberflächentechnik GmbH

48488 Emsbüren

Germany