- Injection moulding

Wirthwein Medical strengthens production capacities with innovative 2K injection molding technology

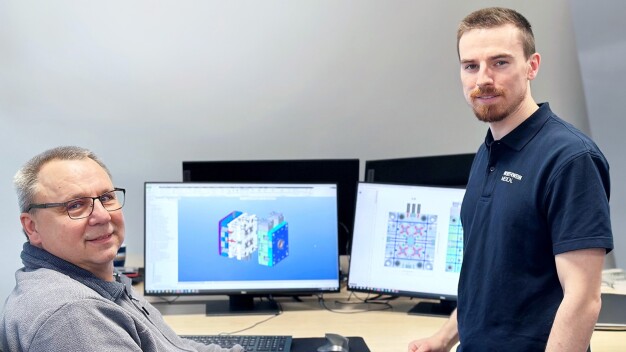

With the introduction of a specially developed, all-electric 2K injection molding machine, Wirthwein Medical is expanding its manufacturing capabilities for high-precision and extremely small multi-component components, including container closure systems and components for pharmaceutical primary packaging. The new injection molding machine was specifically tailored to the specific requirements of the Mühltal-based company and offers a combination of the highest precision, innovation, and automation.

2K technology for demanding applications

A special feature of the new 2K injection molding machine are its two flexibly configurable plasticizing units. Each of these units can be equipped with either a standard cylinder or a micro module with an 8 mm screw. This versatility enables the efficient production of both high-precision micro 2K injection molded components and standard 2K injection molding applications.

Of particular note is the innovative micro-module, which enables the processing of even the smallest material quantities. By using a screw-type plasticizing system instead of a conventional piston, as is common in other micro injection molding machines, significantly improved material homogeneity is achieved. This leads to consistently high melt quality and more efficient series production.

"The micro module is a true innovation in injection molding technology. It enables us to process the smallest quantities of material with exceptional precision in series production, which is particularly crucial for the manufacture of delicate medical technology components.", emphasizes Timo Reifenberger, responsible for application technology at Wirthwein Medical.

In addition, the machine is equipped with advanced automation and a 6-axis robot that removes and deposits the injection-molded parts in a cavity-clean manner. To further increase process reliability, the injection molding machine can be equipped with 100 percent camera control, enabling automatic quality inspection in real time. It also meets the highest cleanliness requirements and is located in an ISO Class 7 cleanroom, allowing pharmaceutical and medical products to be manufactured under optimal conditions.

During the development process with the machine manufacturer, the contribution of specialists from within Wirthwein Medical was particularly beneficial. With their in-depth knowledge and industry-specific experience, they contributed significantly to the development and implementation of this state-of-the-art technology.

Production of sustainable components for pharmaceutical primary packaging

The 2K injection molding machine produces essential components for the pharmaceutical industry with extremely small shot weights. The soft TPE components used ensure the secure packaging and sealing of pharmaceutical products, especially liquids or sterile preparations that must be protected from contamination and environmental influences. Defective primary packaging could compromise the quality and safety of the product and thus have serious consequences for patients.

Using the Container Closure System as an example, it was important for Wirthwein Medical to develop a solution for the soft component that not only meets the complex requirements of primary packaging but also enables 100% recyclability. This was achieved using a specially developed, patented TPE material. Thus, Wirthwein Medical offers an environmentally friendly, functional, and safe packaging solution.

The currently smallest 2K component for use in prefillable syringes weighs less than 0.5 g, with the proportion of soft components below 0.1 g. The 2K design has allowed for the integration of various additional functions, including the optimization of barrier properties.

“We are proud to contribute to reducing waste in the pharmaceutical industry and to offer environmentally friendly packaging solutions in this sector.”, emphasizes Andreas Dunz, project manager at Wirthwein Medical.

The production of these systems requires the highest precision, especially due to the very low shot weights. With the new, innovative 2K injection molding machine, Wirthwein Medical ensures that the material quantities are precisely metered to precisely form the delicate components.

Through this technological advancement, Wirthwein Medical is strengthening its position as an innovation leader in medical technology and is contributing to the development of sustainable, high-quality packaging solutions for the pharmaceutical industry.

Wirthwein Medical GmbH & Co. KG

64367 Mühltal/Nieder-Ramstadt

Germany