- Cleaning | procedures, devices, agents, media (Wipers, Swaps,...)

Innovation for greater process reliability in component cleaning

Intelligent update for Libelle Cleaner Control - Fraunhofer Institute confirms eIffectiveness

The Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Germany confirms the function and accuracy of BvL Oberflächentechnik GmbH's existing measuring equipment. With the latest technical update, BvL's Libelle Cleaner Control sets new standards in the reliability of monitoring and controlling industrial cleaning processes.

Optimum cleaning thanks to precise control and regulation of the detergent concentration

Continuous monitoring and precise dosing of the cleaning chemicals is of central importance in component cleaning. Reproducible and high-quality cleaning results can only be achieved if the concentration and composition of the cleaning medium are kept within the optimum range. At the same time, precise dosing helps to minimize the consumption of cleaning media, which has both economic and ecological benefits.

This becomes particularly challenging under difficult operating conditions. In many real production environments, the cleaning baths are exposed to dynamic interference: oil residues, entrained particles, air inclusions, flow turbulence or changing temperatures influence the composition of the medium and make reliable inline measurement difficult. Conventional sensor systems can deliver inaccurate or fluctuating measured values under such conditions - with direct consequences: Overdosing leads to unnecessary consumption as well as increased costs. While underdosing impairs the cleaning effect. Both can cause subsequent problems in downstream processes.

Such uncertainties are unacceptable, especially in sensitive applications, such as in automotive and aviation technology, where the cleanliness of components is relevant to safety. Precise, robust and process-reliable sensor technology is the key technology for ensuring both cleaning quality and resource efficiency in the long term.

New: The Libelle Cleaner Control update makes all the difference

BvL Oberflächentechnik GmbH has further developed its sensor technology, delivering tangible added value: the Libelle Cleaner Control delivers more stable and reproducible measurement results, even under difficult conditions. The cleaning medium can now be dosed and analyzed even more precisely - this reduces consumption, increases efficiency and noticeably improves process reliability.

This is made possible by two decisive technical improvements:

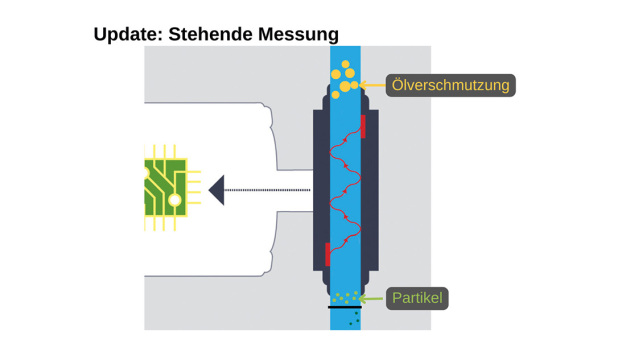

– Standing measurement instead of measurement according to the flow principle

– Automatic cleaning: An integrated cleaning function removes deposits from the sensor at regular intervals - reliably and without manual intervention.

Both functions have been submitted for patent application and are now an integral part of BvL Libelle Cleaner Control. “This is a big step and a real benefit for our customers,” reports Bernhard Sievering, managing owner of BvL Oberflächentechnik, "the result of our innovation is reliable measured values, precise dosing, less cleaning agent and therefore noticeably more process reliability. The Fraunhofer Institute for Manufacturing Engineering and Automation IPA has tested all three of our Libelle products - Fluid Control, Oil Control and Cleaner Control - as part of comprehensive tests and confirmed their function. The conclusion: the systems do exactly what they are supposed to do - practical, reliable and with clear added value for industrial applications."

BvL Oberflächentechnik GmbH

48488 Emsbüren

Germany