- Products, devices, systems, plants for applications

Paths through unexplored territory

New large-scale equipment ‘Pathfinder’ strengthens pharmaceutical process engineering at TU Braunschweig

The Centre for Pharmaceutical Process Engineering (PVZ) at Technische Universität Braunschweig has expanded its biotechnology facility with a state-of-the-art plate separator from the GEA Group. With continuous progress in biopharmaceutical research, the need for high-performance technical infrastructure is also growing. A central process step in biotechnological processes is the efficient and precise separation of cells and culture supernatants, which can now be carried out gently and efficiently with the new large-scale equipment. This opens up new possibilities in bioprocess engineering and supports the complete mapping of the value chain of biotechnological processes on a pilot scale.

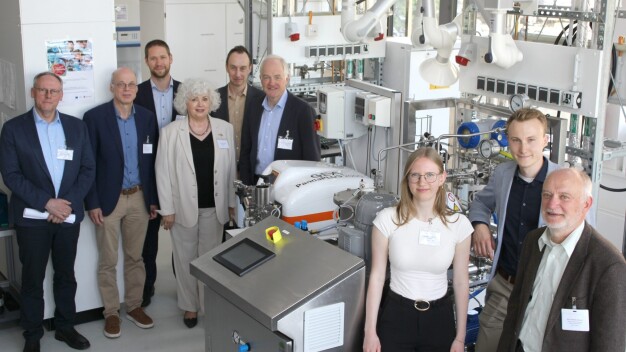

The new large-scale device was officially put into operation at the PVZ on 1 May 2025: The GEA Pathfinder separator is specially designed for biopharmaceutical pilot plants and enables throughputs of up to 200 litres per hour. From pre-culture and cultivation to cell separation and active ingredient purification, the biotechnological value chain can now be realised at the PVZ.

The Pathfinder enables extremely efficient cell harvesting from large bioreactors with volumes of up to 100 litres. The device achieves outstanding separation performance with up to 20,000 times the acceleration due to gravity and continuously removes even the finest particles and cell fragments from the cultivation media. Its hydrohermetic inlet ensures particularly gentle product handling – shear forces are minimised, which protects product quality. The self-cleaning drum enables fully automatic cleaning-in-place (CIP), while GMP-compliant certifications meet the requirements of pharmaceutical production.

This powerful complete package supports fast, scalable and reproducible process control – an essential prerequisite for the development of next-generation biopharmaceutical products.

Research for tomorrow’s medicine

Around 100 scientists from the fields of pharmacy, biotechnology, process engineering and other natural and engineering sciences work together on an interdisciplinary basis at the PVZ. The aim is to develop innovative manufacturing processes for individualised biopharmaceutical products. One focus of the ‘Pharmaceutical-Biological Process Engineering’ department is on the biotechnological production of active ingredients such as therapeutic proteins, antibodies for immunotherapy, enzymes for industrial biocatalysis and new antibiotics – key technologies for the medicine and pharmacy of the future.

Strategic partnership with GEA

In addition to basic research projects, the use of the new separator also forms the basis for application-oriented industrial research and development collaborations. Starting in summer 2025, two industrial projects led by Professor Rainer Krull and M.Sc. Jan-Angelus Meyer from the Institute of Bioprocess Engineering will begin, building directly on the expanded technical capabilities of the PVZ.

“The PVZ will thus offer expanded cooperation opportunities for partners from the pharmaceutical and biotechnology industries in the future – with the aim of jointly advancing practical and innovative research,” says Professor Rainer Krull from the Institute of Bioprocess Engineering at TU Braunschweig.

Technische Universität Braunschweig

38106 Braunschweig

Germany