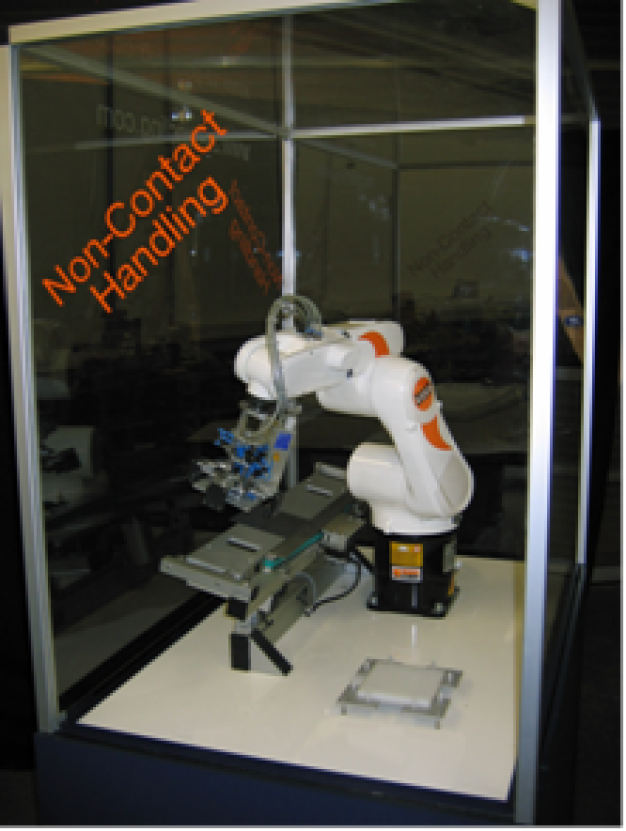

KUKA robot brings progress into the pure area

KUKA robot Switzerland AG shows together with Carpenter & Schilp operations technology AG contactless handling�� �No Zauberei, but most modern technology presents the KUKA robot Switzerland AG in a pure room module.� It acts around an application, which is based on the technology � of the contactless grip arm �. Together also� the company Zimmermann & Schilp operations technology AG in Regensburg developed, ensured the cell� already on mediSIAMS the 2009 for attention ultrasonic oscillations, which lie with a frequency of over 20kHz above the human aural acuity, help to this uncomplicated solution, which can be installed problem-free on each usual wafer Handler. The ultrasonic is generated by oscillators, which are supplied by a separate power electronics. In order to avoid each mechanical contact between tool and disk surface, in the gap between grip arms and wafer by ultrasonic a high-consolidating, basic Gasfilm is produced. Thus the wafer floats frictionlessly on the Gasfilm and by the attacks is fixed. The grip arm dimensions are co-ordinated with standard wafer cartridges and have within the grip arm range a maximum height of 5.9 mm.�� �No wedging and no contact an ideal application for the pure area�� �With this innovative solution a broad spectrum of goods can be handled. Only the surface finish of the articles must correspond to certain conditions. So those should be sound hard to a large extent flat and reproducibly, as well as. Clearly that this contactless and careful form of handling is predominantly for the pure area of the electronic industry in the range silicon wafer or plasma panel handling interesting. But there this technology cannot only be used. A multiplicity of further applications can profit from this innovative technology. So biological chips and flat screens know also glasses, worked on surfaces, painted construction units, coatings, scratch-sensitive components or printed parts on to be handled with it beside semiconductor wafer and � elements. Thus advantages move into the foreground owing to this technology, which become ever more important nowadays. The renouncement of compressed air feed circuit for the production of the state of suspension is thereby only one of many positive aspects. Also the small requirement of the infrastructure during such a handling is an argument. Finally also dynamic gas eddies are avoided, what again a special advantage for the pure area represents, because so no influence is expenditure-practiced on the flowing state. And the small energy consumption makes the solution the genuine future technology. KUKA robot thousandfold examined and for the pure area works satisfactorily�� �But the technology of the grip arm does not only make an application indispensable for the pure area. Rather these grip arms need also the suitable robot. And to these the pure area makes special demands such as particle freedom, which the KUKA pure area robot fulfills on highest productivity level. Tested of the Fraunhofer Institut according to DIN EN ISO criteria these robots therefore highest Anspr�che.Als world-wide only manufacturer fulfill offer to KUKA a complete pure space line for loads from 3 to 500 kg. Like that it is guaranteed that all resulting process steps can be covered with only one robot development environment. Besides a robot series is to future-oriented users here at the disposal, which offers a maximum at speed with absolute precision. With particularly laid out materials and optimized seals KUKA robots are perfectly appropriate for the pure area therefore. Thus a KUKA robot and a contactless grip arm an irresistible combination for the pure area are together, flexible and equipped for each kind of application.�

This text was translated automatically.

KUKA Roboter Schweiz AG

5432 Neuenhof

Switzerland