-

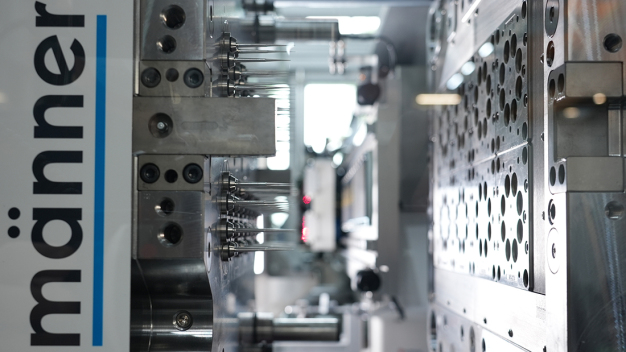

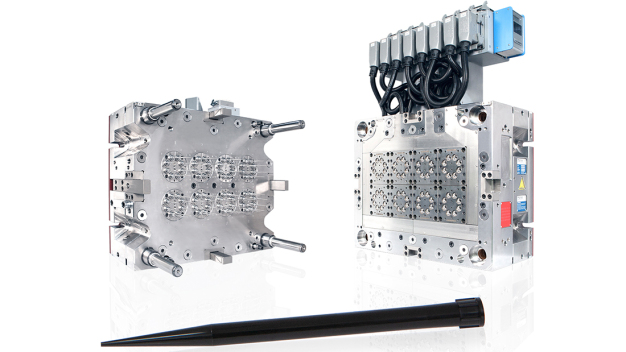

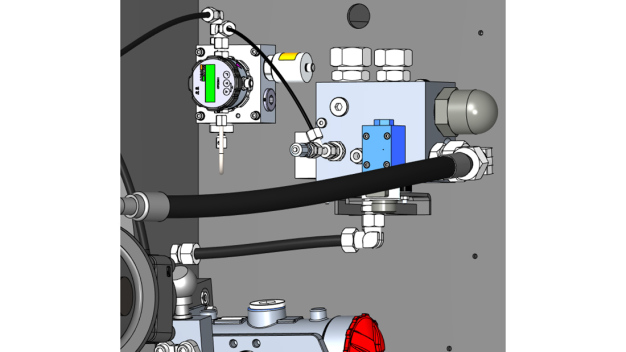

- Injection moulding

Talk by Gerd Liebig, CEO of Sumitomo (SHI) Demag, on the occasion of the LAPP trade press event

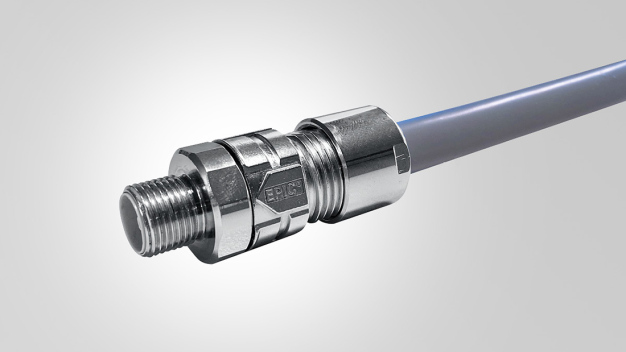

Connectors at their limits – into the future with green intelligence

Gerd Liebig, CEO of Sumitomo (SHI) Demag Plastics Machinery GmbH, outlined how high-quality connector production can be designed cost-effectively and sustainably in the future in a talk held during the LAPP trade press event. He drew a bridge from the trends in customer requirements and machine gene…