Water purification made to measure

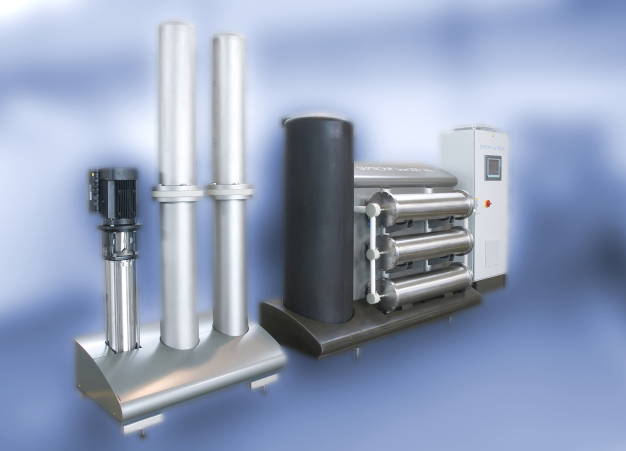

Compact design, maximum variability and high-quality technology - these are the characteristics of the Septron LINE 100-300. With the extension existing of the equipment family the Christian Water Technology Group offers a new individual and solution ready for installation for the water purification made to measure. the modular structure of the line makes possible a composition meeting demand of individual equipment components. Units to the electrode ionization (EDI) and reverse osmosis (RO) can be positioned independently combined as well as. These are available in two versions: The before-qualified VAL execution corresponds to the particularly high requirements of the pharmaceutical industry. Thus produced Aqua Purificata fulfills all editions of the European (pH. Eur.) and American (USP) Pharmakop�en around a multiple. Highest micro-biological purity is guaranteed by the clearance volume-poor connection technique. For application in the general industry however the variant PRO is the ideal partner. Of their produced high-purity water is used for example to rinsing purposes into the solar cell and printed circuit board manufacturing versions has in series a Siemens SPS control with 12" - Touch screen display for process visualization. Owing to WIN CC flexible is completely simple the operation. Besides optionally a audit Trail function and a DATA recorder can be merged into the system. These serve the complete backtracing of all events and interferences as well as the 21 CFR conformal recording of all operational data. Together with the four password levels is provided in such a way for maximum process and quality assurance. Past Septron of LINE products is limited in their achievement for high-purity water production on 2.000 l/h. The new equipment line however possesses capacities from 3.000 to 9,000 l/h and becomes highest quality requirements fairly. An extension of the existing system around additional equipment construction parts can take place at any time problem-free. Fast availability and start-up of the elements are certain due to the series concept. Beyond that the compact building method of the devices permits the space-saving employment on an area of 2,6 m2 to minimum utility space. This makes largest flexibility in the plant planning and highest economy possible in the manufacturing caption: The new Septron LINE 100-300 converts tap water fast and surely into high-purity water. The housing consists of special non-corrosive chassis material also easily cleaning smooth surface photo: Christian Water Technology Group

This text was translated automatically.