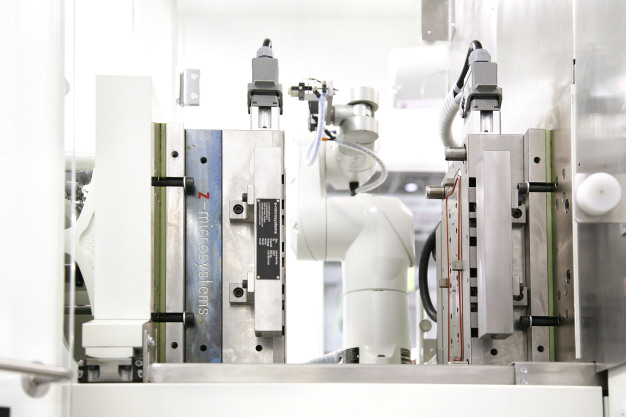

Clean thing - injection moulding machine with integrated robot under pure space conditions

The production of medicine-technical products belongs to the most sensitive ranges in the machine and equipment construction. Hundred percent of control of the production processes under pure space conditions is called one of the central requirements within the Medical range, which a spraying casting cell fulfills pure space robot of St�ubli, integrated by angel with, reliably. Angels conceived the premiere of one for pure space requirements e-victory 50 on the plastic world guidance fair K 2007 ensured at the specialized public for attention. The total conception for the production of medicine-technical components and medical mass-produced article offer an interesting and economical solution from a hand to the users. The injection moulding machine with 500 kN closing force is qualified after GMP for the employment in the pure area. Dipl. brings the crucial advantage for users - engineer Christoph Lhota, leader division Medical with angel Austria, on the point: � our customers get when desired a functioning, ready for occupancy spraying casting cell with all components from a hand from us. After the slogan Plug & Play can begin the user with it immediately with the production of its medicine-technical parts. If the partial spectrum changes, the cell can be adapted owing to high flexibility, which is reached not least by the employment of a Sechsachs robot for the partial handling, fast and uncomplicatedly to the new task spectrum. � the partial spectrum, which can be squirted on the machine, is broadly diversified. In principle it concerns medicine-technical products for a mark use. The spectrum is enough from medicine supply systems such as syringes, infusion sets, Transfusions and dialysis equipment over centrifuges, blood filter, Inhalatoren, diabetes Care products up to implants for the adjustment of fractures. With the fair premiere on the D�sseldorfer K the machine on highest purity conditions produced micro-fluid test elements, so-called � lab on A chip � (LOC), which was packed still in the pure area in bags. This LOC�s serves to the fast analysis of body fluids locally, which is possible today in large laboratories. The machine developed angels according to c�GMP regulations (Good Manufacturing Practice current) the US-American FDA (Food and Drug administration). In order to be able to realize the development on material conditions, the Austrians invested sword mountain in the application technology center in the parent plant into a pure area of the class 6 according to DIN EN ISO 14644-1. � round 95 per cent of Medical applications in the plastics engineering run under pure class of area GMP C+D, which corresponds to ISO 7 and 8. The pure space fitness of our machines fulfills these requirements without reservation. If necessary we can fulfill also stricter requirements. For the assigned St�ubli TX 40 in pure space execution the adherence to this pure class of area is not a problem �, like that Lhota. The robot reached even the much more fastidious pure class of area ISO 4.Holmlose closing unit with significant VorteilenDie characteristic angel victory of the injection moulding machines exists in the cross-beamless closing unit. This design, which in such a way offers angels according to statement of Christoph Lhota only, saves some crucial advantages. In addition the freely accessible fitting space for the tool and much place for the integration of the robot belong within the machine. Further plus of the cross-beamless construction: It offers ideal conditions for the employment in pure areas, because the cross-beams are avoided as splash guards been void and turbulences by breakdown outlines in the laminar pure spatial air river. Why angel Austria� among other things Dipl. uses, brings the St�ubli TX 40 in this cell - engineer Christian OF Lhota on the point: � a criterion was naturally the factory-installed given pure space fitness of the TX 40. In addition however the extremely compact building method of this robot, the one simple integration comes within the machine permitted at optimal position. That is, we must the robot not over the product place, but can him on one level with to the product set up, which affects the laminar river of the air, which in pure areas too over 90 per cent of the cases from top to bottom runs, not negatively. � in addition have St�ubli straight within the medicine range a particularly good image. In principle angels in addition, robot of other manufacturers can integrate, however only under the condition that these robots exhibit the demanded pure space fitness. Simple operation RobotersDie integration of the St�ubli of robot into e-victory the machine makes itself in a further point, which pays simple operation. With VALplast St�ubli one offers developed application software, which simplifies the operation and programming of the robots within the spraying casting range highly in self-direction. The binding at spraying casting automats is made fast and simply by the standardised euro map interface. The intuitive and user friendly surface permits the fast programming of the robots. Pre-defined functions and components facilitate the production of programs and courses of motion substantially. Deep special know-how is not necessary therefore. The field of the robot within the machine is limited to pure handling operations.� The TX40 takes over the withdrawal of the parts from the form and the placing on a conveyor. With the increased temperature level in the spraying casting cell the Sechsachser gets along in the best way thereby. Also variations in temperature between approach with beginning of layer and the work after some production hours leave the robot cold. The high precision of the robot is by far sufficient for these applications. Apart from the compactness and pure space fitness the reliability of the St�ubli machines had highest priority for angels. � the robot, stands also the whole machine stands. And losses of production can want and we at all to afford �, so Lhota. Linear systems versus robot angels builds over 1000 own linear Handlingsysteme for injection moulding machines annually. The fact that one decided with this machine to the integration of a six-oh robot explains Christian OF Lhota: � application determines the assigned component with us. We normally use our linear systems, if their control must be integrated completely into press control and if it depends on extremely short cycle times. Sechsachs robots however are then used, if under pure space conditions must be worked and if the cell must be very compact, the withdrawal handling thus within the cell to be integrated are. A further reason for the employment of Sechsachsern can naturally generally lie also in the assumption of follow-up operations at the Spritzgussteil and in the high flexibility. � construction and manufacturing of grip arms transfer the Austrians likewise gladly to self-direction. One falls back already once to a Standardmodul of the well-known manufacturers, all further adaptation and individualizing work settles one then however in the own house. One uses high manufacturing depth, which is often misunderstood in this country as deficiency, in Austria consistently for the own advantage. One is fast, flexibly, independently. And not only with the building of grip arm picture: The cross-beamless closing unit saves some crucial advantages like freely accessible fitting space for the tool and much place for the integration of the robot within the machine.�

This text was translated automatically.