Contamination Control

Cleaning and disinfecting procedures for controlled environments

In a controlled environment cleanliness is measured by the amount of airborne and surface particles present within the area. The highest contributing factor of contamination is caused by personnel in the form of fibers, hair, skin flakes and bacteria.

A person in a sitting position produces about 100 thousand particles, a person walking 5 miles per hour produces 10 million.

Effective contamination control procedures are key to a functional and efficient cleanroom. When choosing a mopping system for your facility there are many variables to keep in mind:

- What size is the area you are cleaning?

- Amount of contamination within the area?

- What level of classification is required?

- Do you need process validation?

Cleaning validation is achieved by demonstrating that the cleaning procedure consistently removes contamination to acceptable levels. Implementing validated standard operating procedures for specific cleaning techniques will guarantee the cleaning can be performed reliably and repeatedly to satisfy a certain level of cleanliness.

A reliable contamination control process requires high-quality cleaning equipment and specialized techniques. It does not matter how effective a cleaning agent is if the cleaning technique utilized by a cleanroom operator is poor. Today’s critical cleaning professionals recommend the use of multi- bucket mopping systems for maximum cleanliness, efficiency, and removal of contaminants.

The following report explains how to control contamination in a controlled environment by utilizing TruCLEAN Mopping Systems and proper cleaning and disinfecting procedures.

TruCLEAN Mopping Systems

Designed to capture and isolate contaminants from cleaning and disinfecting agents, TruCLEAN multi- bucket mopping systems provide the ultimate in cleanroom cleaning technology.

Each mopping system component will play an important role in delivering the highest level of cleanliness. For example, our low-profiled swivel mop frame allows mopping in an “S” motion, uniformly applying cleaning and disinfecting agents. The stainless steel wringer has a unique wringing mechanism that exerts force evenly across the entire mop surface, extracting the maximum amount of soiled contaminants. Debris is released through hundreds of apertures combined with natural gravity flow, transporting contaminants from wringer into the waste collection bucket.

TruCLEAN mopping systems effectively:

- Remove non-viable and viable contamination

- Dislodge biofilms

- Remove residues

- Apply disinfectants or detergents

- Easy to use, ergonomic

Clean, Disinfect or Both?

Cleanrooms in pharmaceutical facilities must be kept in a state of microbiological control. This is achieved by using specific cleaning techniques along with the application of detergents and disinfectants. The object is to reach a specific level of cleanliness for the class of cleanroom for an appropriate period of time.

Cleaning and disinfection are commonly confused as the same action. Cleaning requires mechanical agitation and the use of a detergent to remove contaminants from a surface. After cleaning, the application of a disinfectant (chemical substance capable of eliminating bacteria or fungus) represents disinfection. If sanitation procedures are performed incorrectly, high levels of microbial contamination will remain and critical manufacturing areas become unstable.

It is important to acknowledge that all controlled environments are not created equal when it comes to proper cleaning methods.

We will now illustrate the appropriate procedures to use with your TruCLEAN mopping system for overall cleanliness and absolute contamination control.

Cleaning Procedure for Contaminant Removal:

1. Set up your three buckets.

Bucket 1: Mopping solution

Bucket 2: Clean water

Bucket 3: Waste collection (Below Wringer)

2. Submerse sponge mop into front bucket in order to activate all cells of the sponge mop. This should take no more than 3 minutes. Unlike disinfecting, cleaning requires firm mechanical agitation of the surface and thorough collection of contaminants. More frequent emptying of the waste bucket will be required.

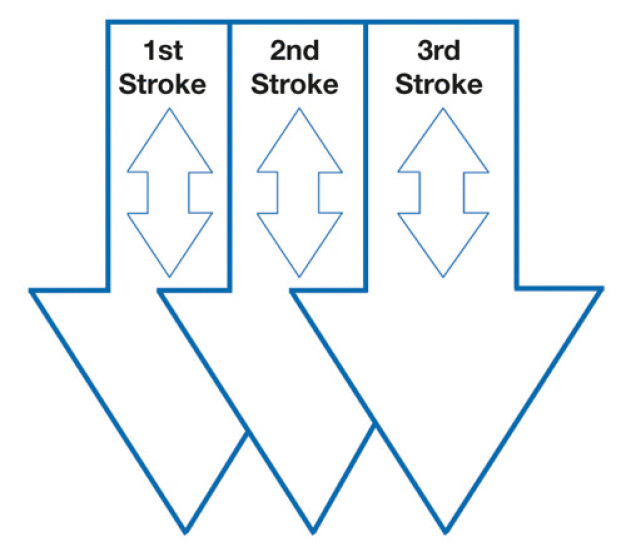

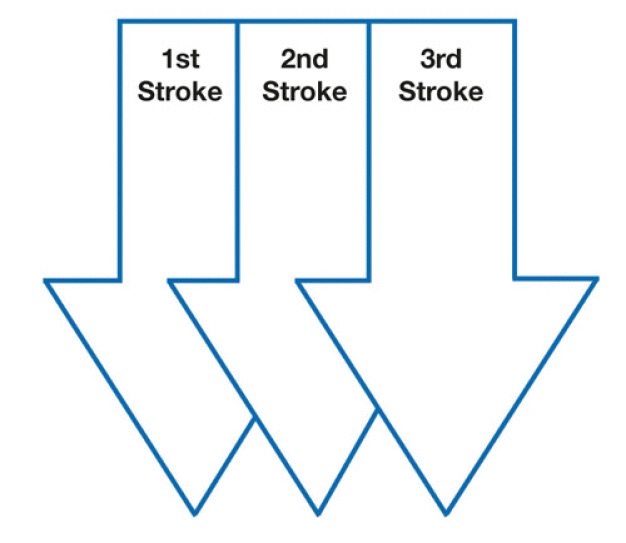

3. Lift sponge mop out of cleaning solution and tilt mop frame on inside wall of bucket to remove excess solution. Sponge is fully loaded and ready to clean. Utilize the “Pull-Lift” technique - pulling the sponge mop towards you, lifting the sponge and over-lapping the previous stroke (see illustration 1). Be firm, agitate the surface back and forth, staying within the unidirectional flow. The cleaning flow should always begin with the cleanest area to the dirtiest. Start with the ceiling, then the walls, equipment, and finishing with the floor. Apply solution as recommended by your chemical supplier.

4. Wring out sponge mop thoroughly. Do not apply unnecessary force on wringer handle.

5. Go back to the cleaned surface and wipe dry using the “Pull-Lift” technique without agitation (see illustration 2). The sponge mop will collect any remaining residue and dry the surface.

6. Rinse sponge mop in center bucket by patting the bottom of sponge on the surface of the rinse solution - then wring out. This process removes residuals from the bottom surface of the sponge mop and minimizes re-depositing contaminants. Do not submerse sponge mop in rinse solution.

7. Repeat steps 2 - 6.

8. When finished, thoroughly rinse entire system and wipe dry. Apply an approved disinfectant onto the entire system or autoclave at 250°F for 30 minutes.

Disinfection Procedure for Pre-cleaned Surfaces:

1. Set up your three buckets.

Bucket 1: Disinfecting solution

Bucket 2: Clean water

Bucket 3: Waste collection (Below Wringer)

2. Submerse sponge mop into front bucket in order to activate all cells of the sponge mop. This should take no more than 3 minutes.

3. Lift sponge mop out of solution and tilt mop frame on inside wall of bucket to release excess solution. Sponge is fully loaded and ready for application to floors, walls, and ceilings.

If dosing surface with contact time of 7-10 minutes or greater proceed directly to surface without wringing. If dosing surface with contact time less than 7-10 minutes slightly wring sponge by applying minute force on the wringer handle. Do not apply excessive force since this will dry out the mop head and cause skipping of the sponge. More importantly, it will result in a non-uniform application of solution.

Utilize the “Pull-Lift” technique, without agitation (see illustration 2). When disinfecting walls, never let the sponge mop touch the floor, you may transfer floor contaminants onto the wall. Apply solution as recommended by your chemical supplier.

4. After applying disinfectant, rinse sponge mop in center bucket by patting the bottom of sponge on the surface of rinse solution. Wring out sponge mop thoroughly. Do not submerse sponge mop in rinse solution.

5. Refill sponge mop in front bucket by submersing only the bottom surface of the sponge mop. Repeat steps 3 - 4.

6. When finished, thoroughly rinse entire system and wipe dry. Apply an approved disinfectant onto the entire system or autoclave at 250°F for 30 minutes.

Conclusion:

Deciding which cleaning method is best for guaranteed compliance with today’s cleanroom standards is a challenging process. For this reason, Perfex Corporation offers vast experience as a trusted manufacturer of high-quality cleaning tools. Our TruCLEAN line of cleanroom mops and mopping systems will surely meet your precise requirements.

TruCLEAN products are methodically designed for healthcare, pharmaceutical, and life science applications. TruCLEAN mopping systems withstand repetitive autoclave sterilization procedures, providing economical advantages.

Perfex Corporation

NY13431 Poland

United States