Optimum results due to part specific workpiece holders

Correct use of part-specific cleaning containers

Parts cleaning applications that require part specific designed workpiece holders are steadily increasing for various reasons. For these uses, Metallform develops and manufactures technically and economically ideal solutions as standalone and insert workpiece holders.

Increasing requirements on the cleanliness of workpiece surfaces, a higher automation level in production, workpieces with critical to clean areas and increasingly complex part geometries are leading to growing demands in parts cleaning. Therefore, part specific designed workpiece holders are becoming more and more important. Due to their optimal design as standalone or insert workpiece holder they make an important contribution to fulfill cleaning requirements needs-based, efficiently and ergonomically.

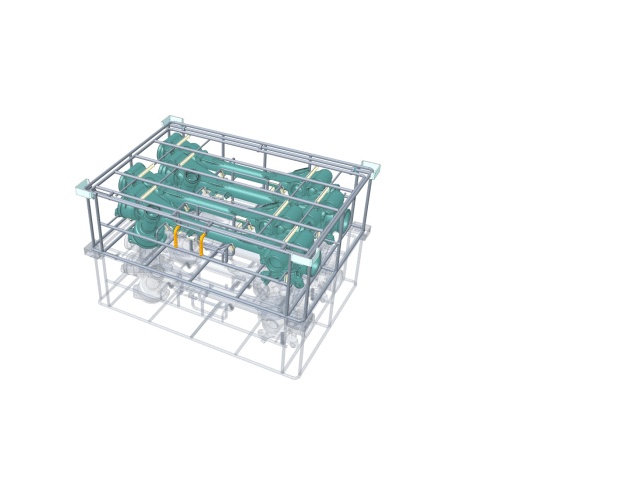

Standalone workpiece holders – ideal for massive and heavy parts

Standalone workpiece holders are used without an outer cleaning basket. The main application area is the cleaning of massive and heavy parts and components which are manufactured in high volume quantities. The weight of these batches is usually too high for manual handling. The loaded workpiece holder is therefore hoisted with a lifting device directly to the cleaning machine’s loading device. As another advantage of this solution, the positioning of parts in the workpiece holder can be optimally adapted to the requirement of cleaning. This includes, on the one hand, the all-around accessibility for the cleaning medium and washing mechanics such as ultrasonics or spray jet. On the other hand, the workpiece can be placed in the holder in such a way that critical to clean areas can be specifically be treated. Additionally, a good automation of parts handling with robots and thus the integration into a networked production environment speak for this solution. The measures of standalone workpiece holders are typically adapted to the batch size of the cleaning machine, which ideally corresponds to the dimensions of a standard cleaning basket. This allows for using the cleaning machine with standalone workpiece holders as well as with cleaning baskets.

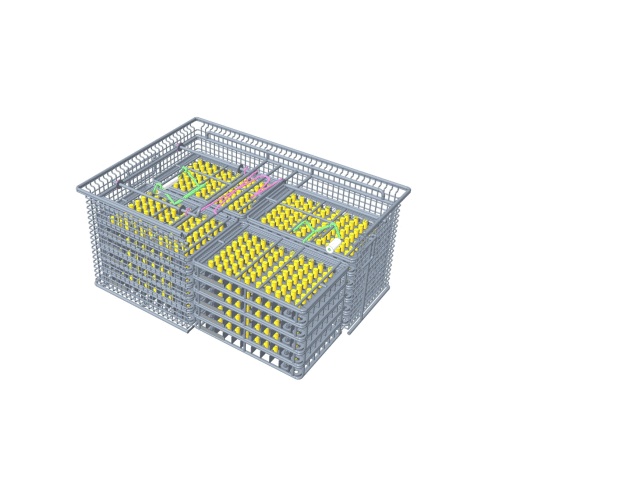

Insert workpiece holders – the more flexible alternative

Characteristic for this solution is that the loaded workpiece holder can be handled manually. For using the full capacity of the cleaning machine, several workpiece holders are combined to one batch and placed into an outer basket. In addition, for gentle parts cleaning the basked allows for building different compartments by using compartment rods. The basket, therefore, can be used for different part specific workpiece holders and compartments as well as for cleaning bulk parts. The higher flexibility is a major advantage of this solution.

Stainless steel in careful workmanship

Metallform manufactures both, workpiece holders and cleaning baskets from stainless steel rounds with electrolytic-polished surfaces. Therefore, the products can be used with all cleaning media, and offer an all-around accessibility due to their open design. Additionally, the high-quality material enables a long service life. The rods of the workpiece holders, as well as the outer structure of cleaning baskets, are butt welded which prevents injury hazardous edges.

Metallform Wächter GmbH

75004 Bretten

Germany