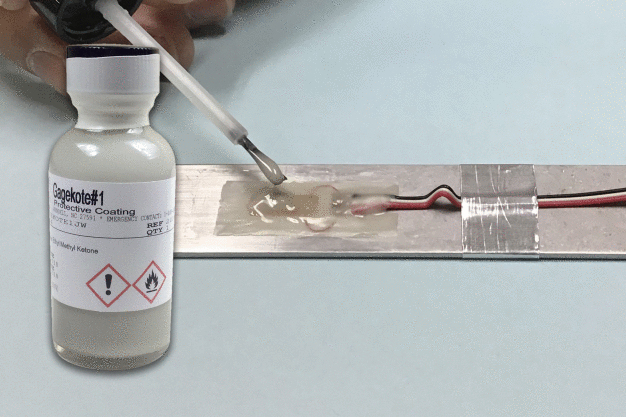

Micro-Measurements Introduces Moisture-Resistant Protective Coating for Maximum Strain Gage Sensor Stability

Coating offers a wide temperature range and helps mitigate field installation failures

The Micro-Measurements® brand of Vishay Precision Group, Inc. (NYSE: VPG), industry experts in the design, development, and manufacture of resistive-foil sensors for high-precision strain, high-stress and force mechanism measurements, today introduced the Gagekote #1, an expansion of the Gagekote Series, a solvent-thinned (toluene) synthetic resin. The Gagekote #1 is ideal for applications in PCB testing, agriculture, civil engineering, automotive, stress analysis aviation/defense/aerospace, education, medical, Internet of Things (IOT), Robotics, Industry 4.0, consumer, Process monitoring, load cell manufacturer. Transportation, Energy, and smart manufacturing industries.

The Gagekote #1, often used as a pre-coat for Gagekote #5 and Epoxylite #813, is resistant to moisture, and offers a wide-operating temperature range that is easily removable after exposure to temperatures as high as 500F. It was designed to provide maximum stability of the strain gage sensor, as moisture is the most common cause of field installation failures.

“A good protective coating such as the Gagekote #1 not only seals the strain gage installation from moisture, but also seals in any moisture in the area at the time of coating application,” said Yuval Hernik, Sr. Director of Sales and Marketing. “In order to provide maximum stability in high-moisture environments, the gage installation should be warmed until all moisture is removed prior to applying the protective coating. Next, the Gagekote #1 coating should be immediately applied after gage and leadwire installation to prevent moisture from collecting in the gage area. One of the advantages of the Gagekote #1, is that it provides a wide temperature range coating and can easily be removed after exposure to temperatures as high as 500F.” (260°C)

Field installation of strain gages present stress analysts with several unique challenges, particularly when long-term measurements are required, and when massive structures or inclement weather are encountered. For example, strain gage sensor performance is easily degraded by the effects of moisture, chemical attack, or mechanical damage. As a result, strain gage sensors require varying degrees of protection, according to the severity of the environment in which they must operate. The Gagekote #1 provides maximum stability of the strain gage sensor through its protective coating that is immediately chemically stable and highly resistant to water-vapor transmission. The coating only protects against incidental mechanical damage, like minor objects lightly coming into contact with the installation, or very lightly dragging across it.

Vishay Precision Group, Inc.

PA 19355 Malvern

United States