Gx Elite Vials – High Quality and Filling Performance

The Gx Elite vials have set new standards for type 1 borosilicate glass vials. They are the result of comprehensive optimization measures in the conversion process, which have focused on designing out the risk to create product flaws during production including the removal of all glass-to-glass- or glass-to-metal-contact beginning with the tubing material all the way through final packaging. The chemical composition of the borosilicate glass still stays the same.

The best in its class

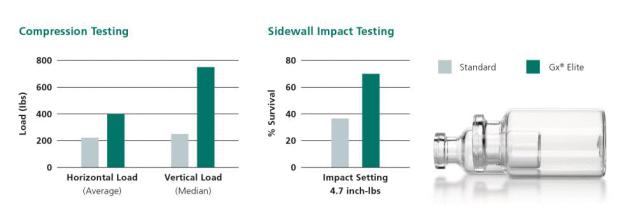

“The Gx Elite vials are the result of several years of careful product development and our customers are really impressed with them too,” says Hans-Ulrich Pieper, Sales Director Europe Tubular Glass Converting at Gerresheimer, emphasizing just how much of an impact avoiding glass-to-glass contact during the production process has on the quality of the vials. The highly shatter-resistant vials are extremely durable and free of cosmetic defects. They also boast an incredibly robust structure, while their resistance to delamination protects the drug inside. Simple handling and a range of packaging options ensure that Gx Elite vials can be supplied for end-to-end use on various filling lines. This cuts costs while improving quality, as countless past and ongoing tests by notable customers have shown.

Intelligent defect recognition

All of Gerresheimer’s tubular glass plants that produce vials work with standardized monitoring, inspection, and packaging technologies, which essentially comprise the Gx G3 and Gx RHOC systems. The inspection systems, for one, are developed in house and form part of a close-knit testing system that ensures the highest precision and quality assurance in line with the latest standards. Complete with modern HD cameras, the Gx G3 inspection system makes sure that cosmetic defects are identified reliably, for instance. The intelligent software detects and classifies the defects in a few fractions of a second, while the Gx RHOC system ensures dimensional quality with HD matrix cameras and a hypercentric ID camera.

Injection vials set the benchmark for primary packaging for parenteral drugs. Gerresheimer’s vials come in all sizes and comply with the relevant international standards and pharmacopoeias. The company’s range includes solutions for bioengineered drugs and other specialist pharmaceuticals.

Gerresheimer AG

40468 Düsseldorf

Germany