Windsor boosts individual injection moulding solutions

During Fakuma WINDSOR demonstrates unusual entrepreneurial diversity with three exhibits: The SD300SV from FCS further expands the company’s offer of servohydraulic injection moulding machines (IMM). Adjacent to it, a fully electric J100ADS from JSW works with an actuator mould for medical device applications. A special highlight is WINDSOR’s own product: the PxP73 is an independent injection unit which virtually sets no limits to upgrading an IMM towards multi-component injection moulding. Obviously, WINDSOR’s exhibits are compatible with the requirements laid down in Industry 4.0 and/or Euromap 77.

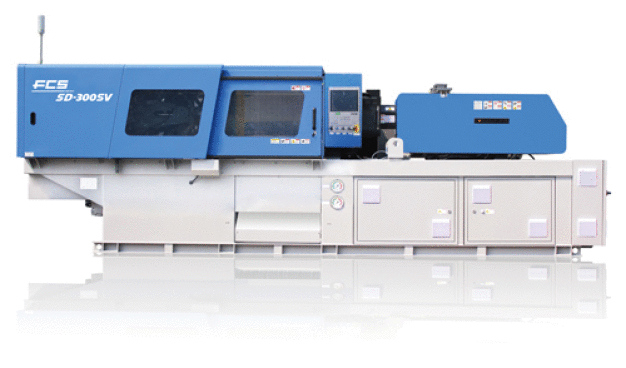

In 2016, Fu Chun Shin Group (FCS), Taiwan, and WINDSOR Kunststofftechnologie GmbH in Hanau, Germany, signed an agreement under which FCS committed to construct and supply hydraulic and servo-hydraulic IMMs according to European standards and specifications as prescribed by WINDSOR. In return, WINDSOR acquires, based on its established sales network developed over 65 years, responsibility for long-term sales, trading, installation, replacement parts supply and service for these 300 to 37,000 kN clamping force IMMs in all EU and EFTA countries. “We have been making great progress with FCS since. The technological status of the machines passes the comparison test with European brands,” says Peter Kochs, WINDSOR’s managing director.

The new FCS machine: WINDSOR operates the servohydraulic SD300SV – 3,000 KN clamping force – with a mould made by Kiranda/Turkey. “The ornamented dish we mould in PP weighs 120 grams and takes a cycle time of barely 15 seconds. A SEPRO robot demoulds the bowls and deposits them on a conveyor belt directly to the visitors”, explains Kochs and ads: “We offer servohydraulic IMMs from FCS because they use the latest and high-end technology in this special segment.” The machines’ quality meets European standards. However, their price level is comparatively low: “The price/performance ratio of the FCS machines is unequalled”, maintains Kochs. After acquiring the pan-European distribution rights for FCS, WINDSOR has been quite successful in marketing toggle SGMs and two-platen machines from FCS and relies on these proven large machines in the future. FCS machines are the choice a great number of applications: they produce components for household appliances, white goods, electronics, toys and also automotive parts to name only a few. Kochs: “There are practically no limits for applications.” The FCS toggle IMMs are available with clamping forces ranging from 30 to 1420 tonnes – complemented by servohydraulic two-platen machines with clamping forces from 500 to 4000 tonnes. Kochs promises: “We strive to improve quality even further and maintain the low-price level.”

The JSW machine: Japan Steel Works (JSW) has contributed a fully electric J100ADS injection moulding machine providing 100 tonnes of clamping force. It is equipped with an actuator mould from KEBO/Switzerland. The machine produces the mentioned actuator components in transparent PP, the parts weighing only 6.8 grams each. They are switch elements for medical devices such as sphygmomanometers and blood glucose meters. The two-cavity mould operates at a cycle time of barely seven seconds including part demoulding. “We have integrated the SEPRO robot control, responsible for demoulding and transportation of the parts, into our IMM control system”, explains Kochs. A special feature of the plant is its data visualization on a 15” android system: regulation and control is effected with a software version used in mobile phones. “JSW was the first IMM supplier offering an android surface”, says Kochs. Control commands such as for instance closing or opening etc. are integrated which are comparable to apps of standard smartphones. This instrument offers the user extremely easy control operations. A predominant advantage of the JSW machines – for which WINDSOR holds the distribution rights for Germany – is their reliability: “The technology is namely state-of-the-art and widely proven. The occasions where wear parts have to be exchanged are very rare, the machines work year in, year out impeccably”, states WINDSOR’s managing director and concludes: “JSW develops and builds fully electric injection moulding machines since 1985. So, their technology is quite sophisticated.”

WINDSOR’s own product: At short notice, WINDSOR decided to also showcase its own product during Fakuma: PxP 73 is a new version within the PlugXPress® range. PxP 73 is a self-contained injection unit comparable to an IMM without clamping system etc. WINDSOR’s great strengths are custom-designed adaptions: “We provide solutions which fit exactly in the plant configuration”, Kochs states. The results are individual systems with individual units. PxP communicates with the IMM via an interface. The customer can attach the PxP easily to the IMM without major changes in the machine. This injection unit operates a three-zone screw available from 16 to 105 mm and uses a B&R control system equipped with a 15” touchscreen. The PlugXPress® injection unit for multi-component injection moulding can be attached to any IMM. Kochs: “One of our customers produces tooth brushes in three different materials and four colours.” This way, six-component IMMs are not unusual. The rising demand in the multi-component sector and the success of the PxP is said to be the reason why its sales volume in 2017 has more than doubled compared with the previous year. “Our strengths are individual custom solutions and we differentiate ourselves from the competition by realizing a great deal of flexibility. PxP works where standard solutions fail”, comments Peter Kochs.

WINDSOR TECHNOLOGIES

63452 Hanau

Germany