Partnership between OHB and Fraunhofer IPA

OHB System AG, a subsidiary of listed space and technology company OHB SE, together with the Fraunhofer Institute for Production Engineering and Automation IPA, has designed a mobile clean room, which was presented at LOUNGES 2018, the trade fair for clean-room and pharmaceutical process technology.

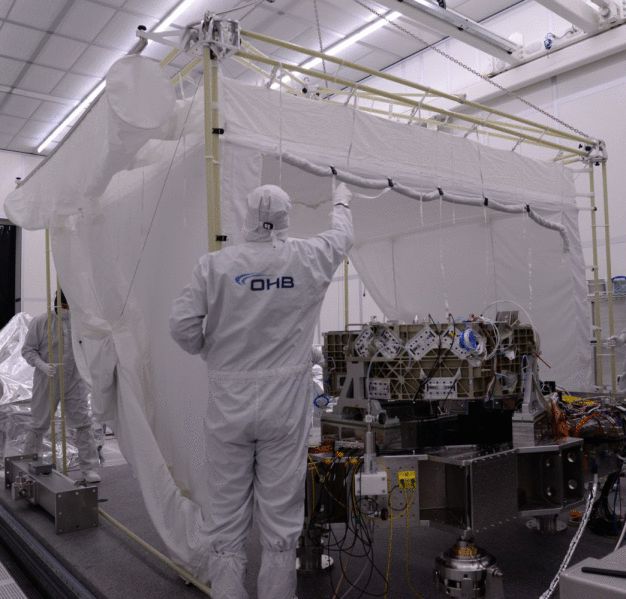

“How can I protect sensitive hardware in a high-purity clean room which is being serviced or modified?” wondered Dr. Axel Müller, Cleanliness Officer at OHB System AG, going on to consider various clean-room situations and possible solutions. He then came up with the idea of developing a mobile and autonomous system which is easy to install and creates its own clean-room environment inside the clean room. He presented his ideas to OHB partner Fraunhofer IPA in Stuttgart, meeting with a welcome response. The experts at IPA were quick to realize the potential and became involved in the production. Their prototype was further developed in conjunction with OHB. The result is the CAPE® (clean and protective environment) mobile clean room that allows users to set up enclosure for their hardware on an area of around four by four meters within a period of a good hour. In addition to the space technology industry, OHB and IPA also see potential demand for mobile autonomous clean rooms in the pharmaceutical, optical, food, medical and the semiconductor industries.

CAPE® provides double protection for hardware and infrastructure

The CAPE® mobile clean room provides temporary protection for all kinds of hardware during product inspections and cleaning processes. Equally, it reliably prevents particle and molecular contamination during new installations, routine maintenance and repairs in the clean room. It can also be used for acceptance testing at suppliers or in test houses for qualifying flight hardware for space applications.

Equally, however, CAPE® protects existing infrastructure. In this case, critical processes such as gluing are performed in the mobile clean room to prevent the rest of the clean room from being compromised.

Tested and approved

CAPE® was used in an ISO5 clean room at OHB Space Center “Optics & Science” for the first time at the end of 2017. “The system not only worked perfectly but also showed potential for modifications and extensions,” says Dr. Müller. “IPA implemented CAPE® extremely professionally. Standardized processes after each use preserve the purity and viability of CAPE® even after storage periods. For this reason, we will provide five systems at OHB to be optimally prepared for all cases.”

CAPE® is not just an off-the-shelf article

CAPE® can be acquired either as a standard product or as a customized model. The design and assembly of the customized models take account of the intended purpose, the desired size and the necessary air purity class.

OHB System AG

82234 Oberpfaffenhofen

Germany